Insect repellant fabrics and its manufacture method

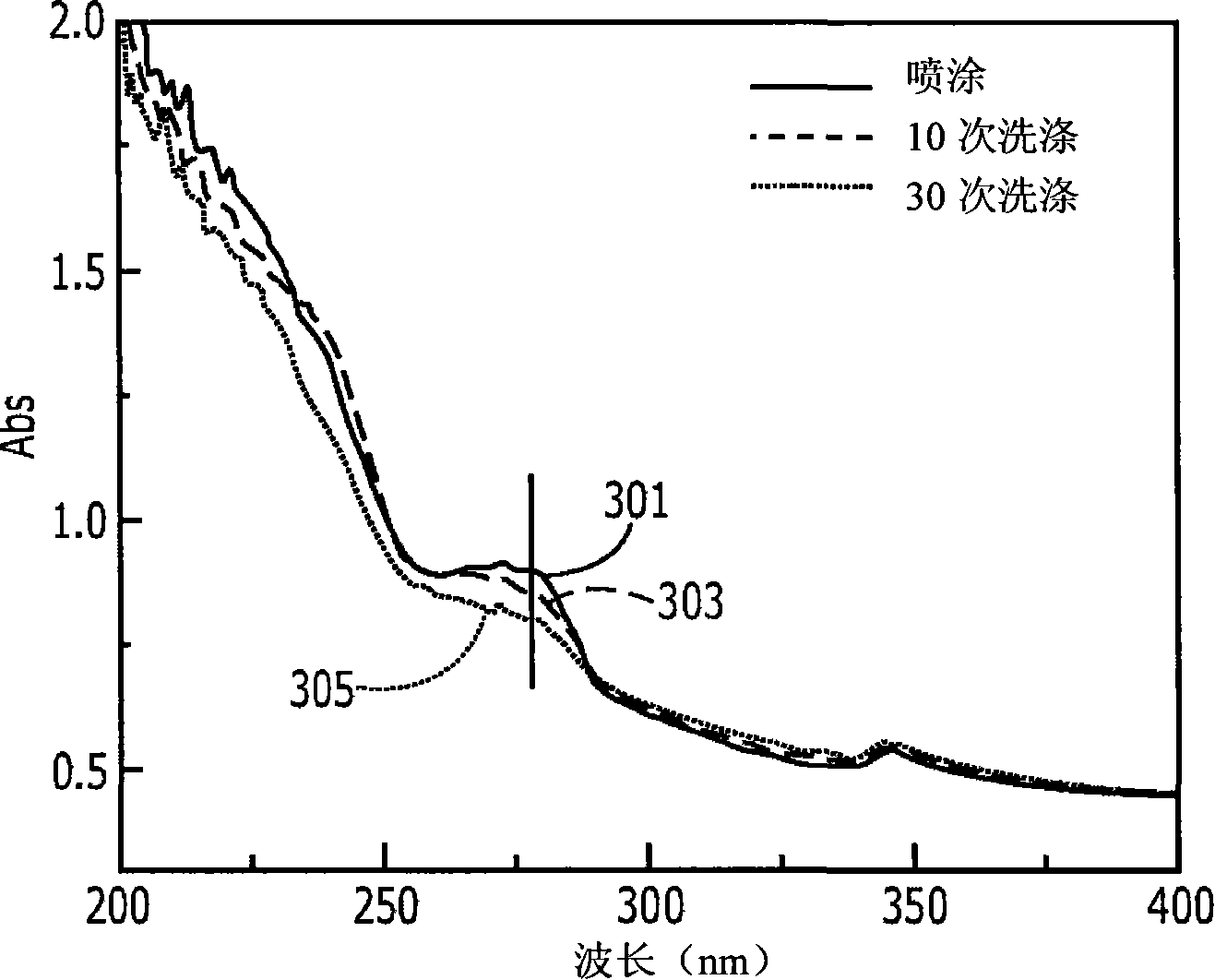

A manufacturing method, a technology for fabrics, applied in the fields of botanical equipment and methods, textiles and paper, animal fibers, etc., can solve problems such as permethrin retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

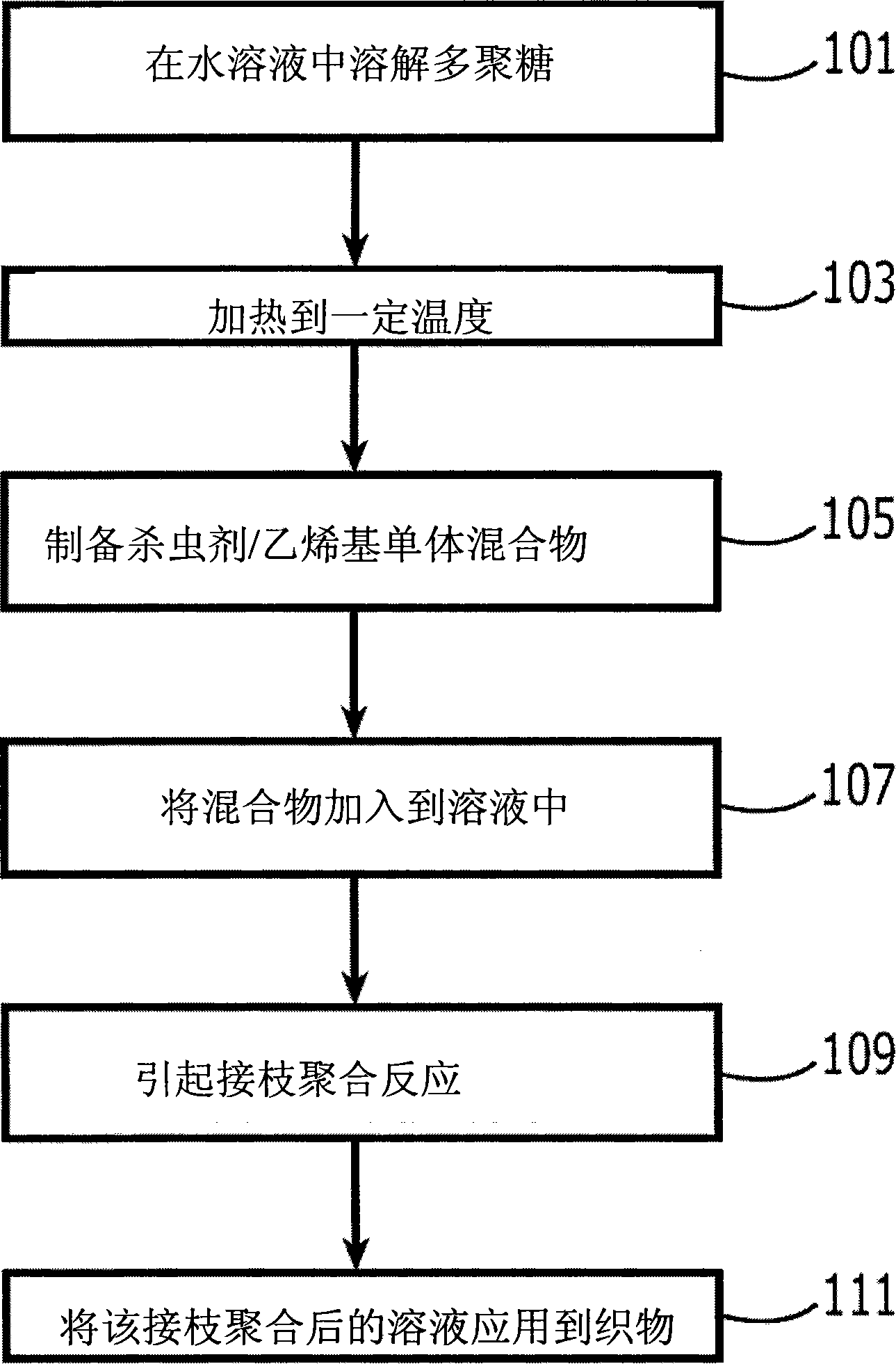

Method used

Image

Examples

Embodiment 1

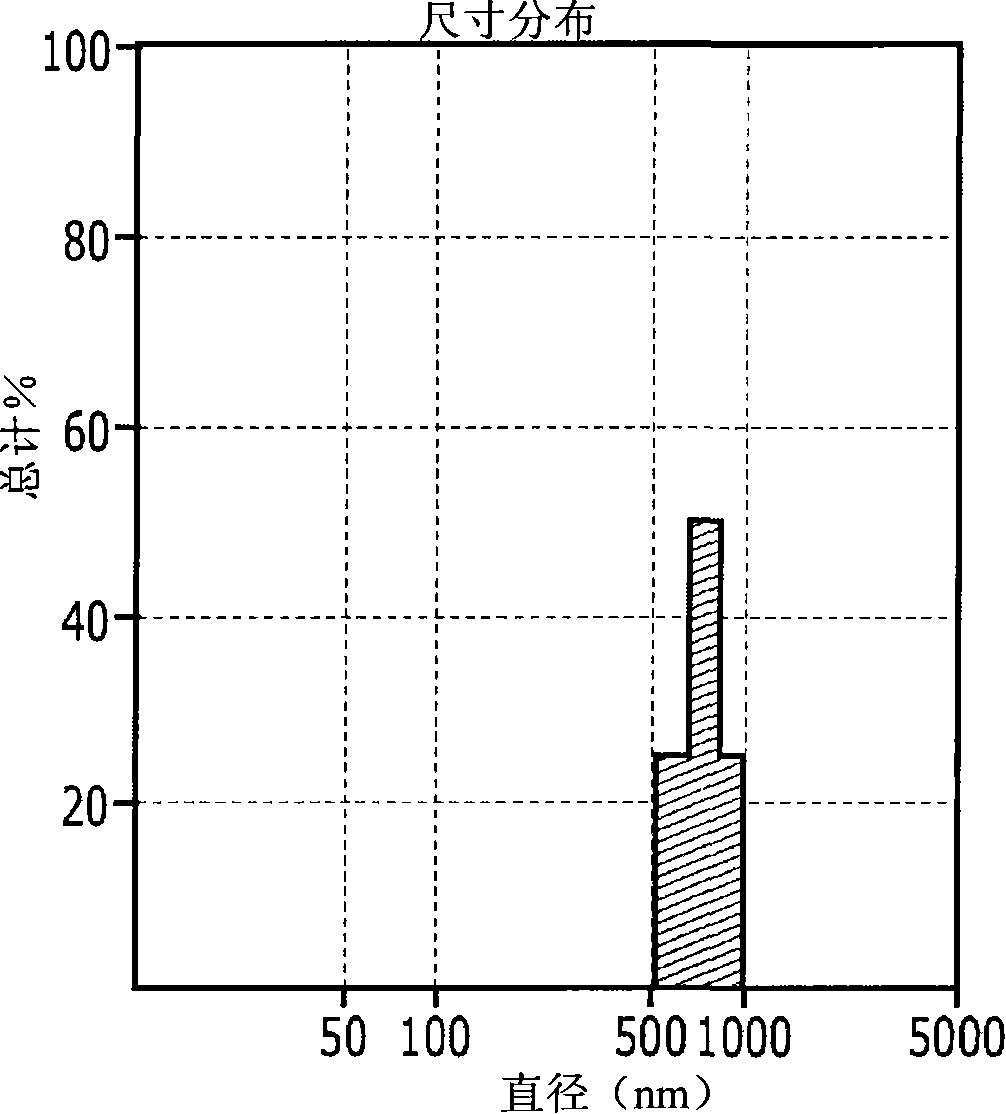

[0064] Mix 97 mL of deionized water with 1 mL of acetic acid, and dissolve 0.5 g of chitosan. After filtering out insoluble impurities, the solution was heated to 80°C in a flask with a condenser, and N 2 , Stir for half an hour. Then, 2 ml of ethylene acetate and 1.0 g of permethrin were added to the above solution, followed by 2 ml of 20 mM tert-butyl hydroperoxide (TBHP) solution. Maintain the reaction at 70°C for 6 hours. The size of the resulting particles is between 500-700 nm. The resulting emulsion was then coated onto cotton / polyester fabric.

Embodiment 2

[0066] 80 ml of deionized water and 0.1 g of NaOH were mixed in a flask with a condenser, and 5 g of amylopectin was added at 70° C. to convert the amylopectin into a gelled state. After the pullulan had gelled, 0.2 g of maleic anhydride was added to the pullulan solution to neutralize the NaOH. Nitrogen was bubbled through the solution for half an hour. A mixture of 10 ml of styrene and 5 g of phenothrin was then added to the solution, followed by 0.5 g of ammonium persulfate. The reaction was maintained at 70°C for 8 hours. The size of the resulting particles is between 500-1000 nm. The resulting emulsion is then applied to cotton / polyester fabric by dipping / coating.

Embodiment 3

[0068] Dissolve 5 g of hydroxyethylcellulose in 72 mL of deionized water. The solution was heated to 60° C. in a flask with a condenser, and nitrogen gas was blown in for half an hour while stirring. Then 10 ml of ethyl acrylate and 5 g of pyrethrin were added to the solution, and then 8 g of ammonium cerium nitrate was added to the solution. The reaction was maintained at 60°C for 8 hours. The resulting polymer nanocapsules range in size from 400 nm to 900 nm. The emulsion is then applied to the fabric by dipping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com