Method and preventing and reducing hydrogen sulfide of aqueous system and promoting oil recovery factor

A water system, hydrogen sulfide technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

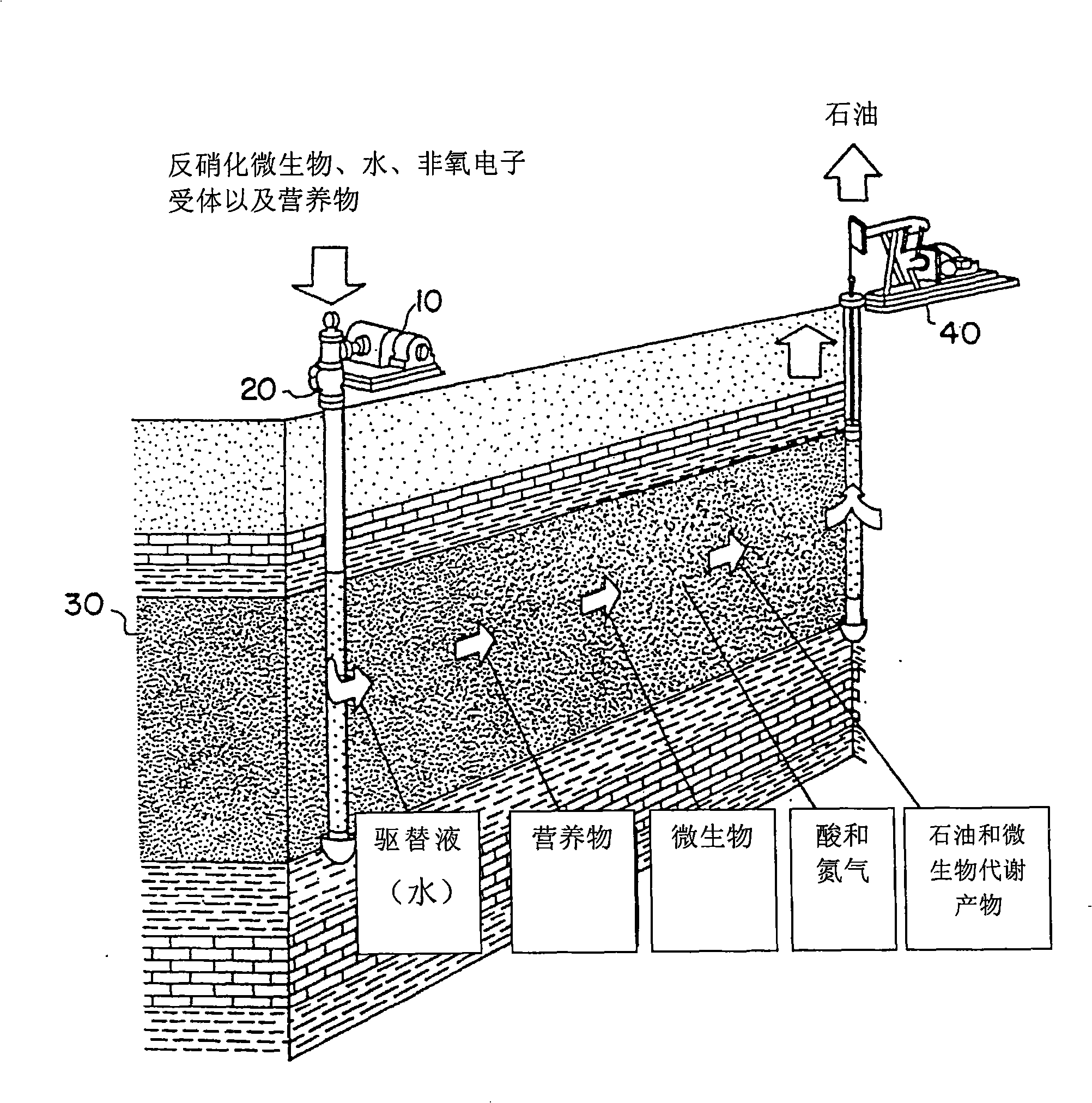

Method used

Image

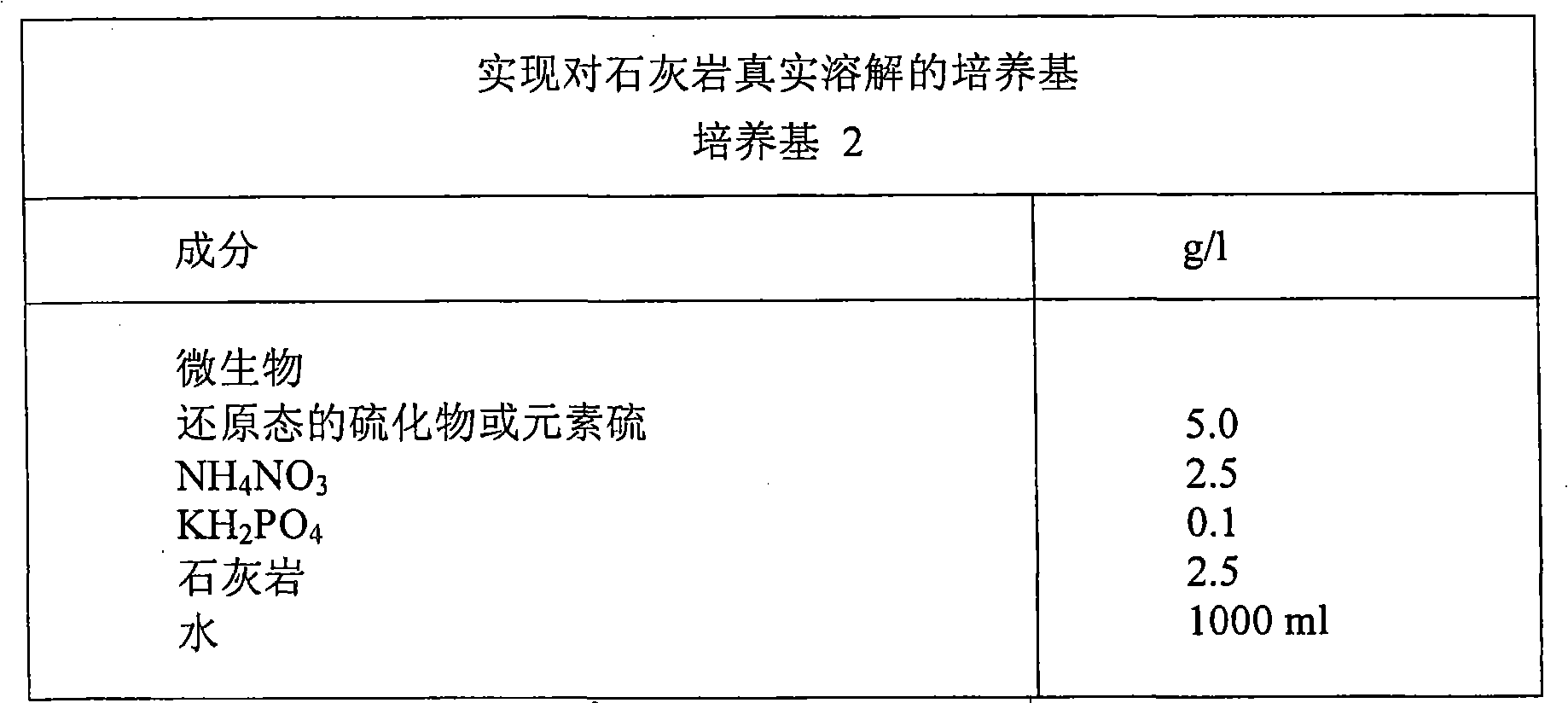

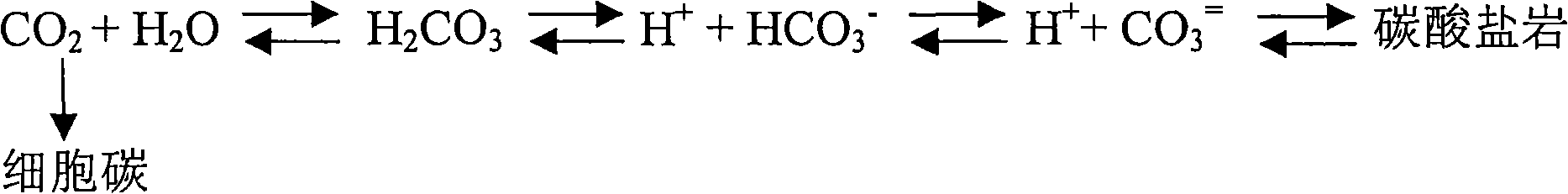

Examples

Embodiment

[0054] The data in the following tables are obtained from laboratory reaction vial tests. A series of sterile sulfate-reducing bacteria synthetic medium test bottles were inoculated with constant numbers of microorganisms, ie, constant numbers of sulfate-reducing bacteria and denitrifying microorganisms. Add different concentrations of chemicals to be tested in different test bottles (samples). The growth of SRB is judged by the formation of sulfide, in other words, the absence of SRB growth can be judged by the absence of sulfide formation. These results are shown in the table below.

[0055] sample number

degree(PPM)

Nitrite ion

Concentration (PPM)

molybdate ion concentration

degree(PPM)

growth

1

500

No

2

200

Have

3

100

Have

4

500

No

5

200

Have

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com