Enzyme electrode and enzyme sensor

An enzyme sensor and enzyme electrode technology, applied in the field of enzyme sensors, can solve problems such as lack of stability, inactivation of enzymes, and inability to obtain detection sensitivity and response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

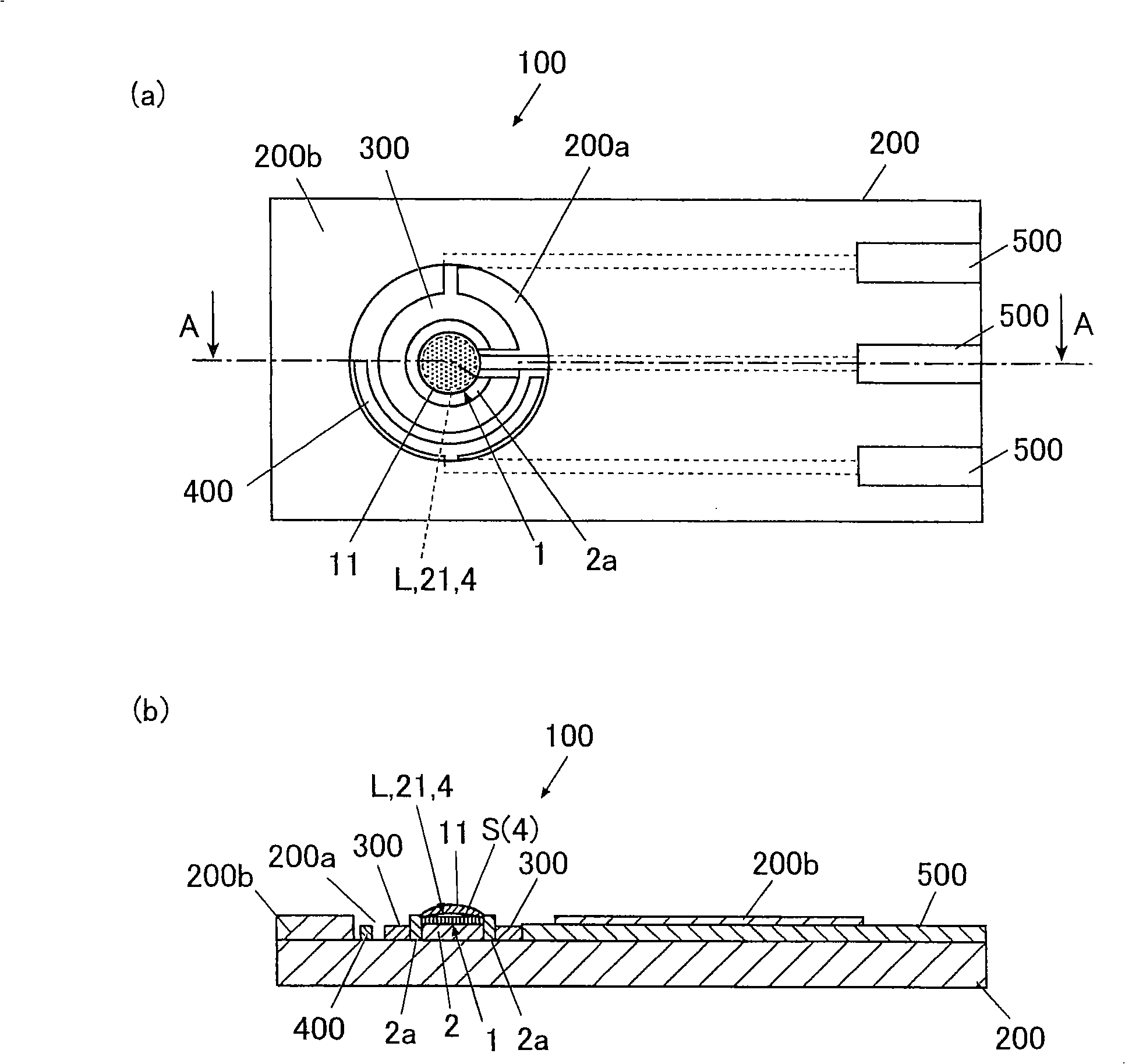

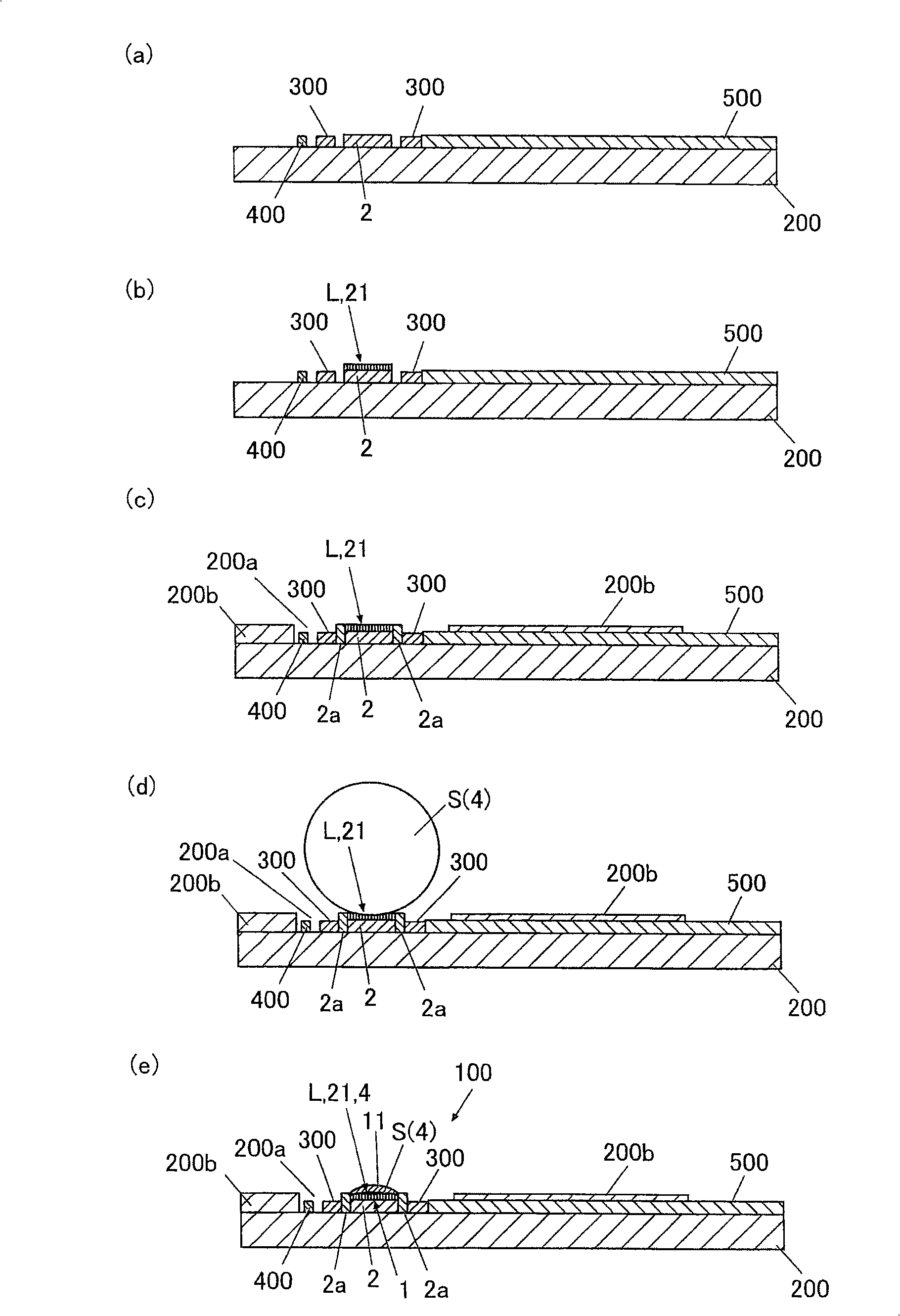

[0128] In Example 1, the enzyme sensor 100 was fabricated by fabricating a base substrate and immobilizing the enzyme 4 on the base substrate to form the enzyme electrode 1 . The enzyme sensor 100 was then evaluated.

[0129] (1) Fabrication of the base substrate

[0130] First, a base substrate is produced.

[0131] (1-1) Fabrication of electrodes

[0132] On the substrate 200, a triode structure of the working electrode (electrode 2), the counter electrode 300, and the reference electrode 400 is patterned.

[0133] Specifically, for example, the substrate 200 made of quartz glass is prebaked at 95° C. for 90 seconds using a hot plate. Afterwards, 50 μL of negative resist was coated by spin coating, and the photomask pattern of the triplet structure of the working electrode (electrode 2 ), the counter electrode 300 and the reference electrode 400 was transferred by an ultraviolet exposure device. Then, post-baking was performed at 120° C. for 60 seconds, development was p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com