Flue gas denitrating whirling current mixer and whirling current mixing method

A mixer and eddy current technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of large system pressure loss, large resistance, large flue area, etc., and achieve strong flue gas adaptability and debugging. Short time, good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

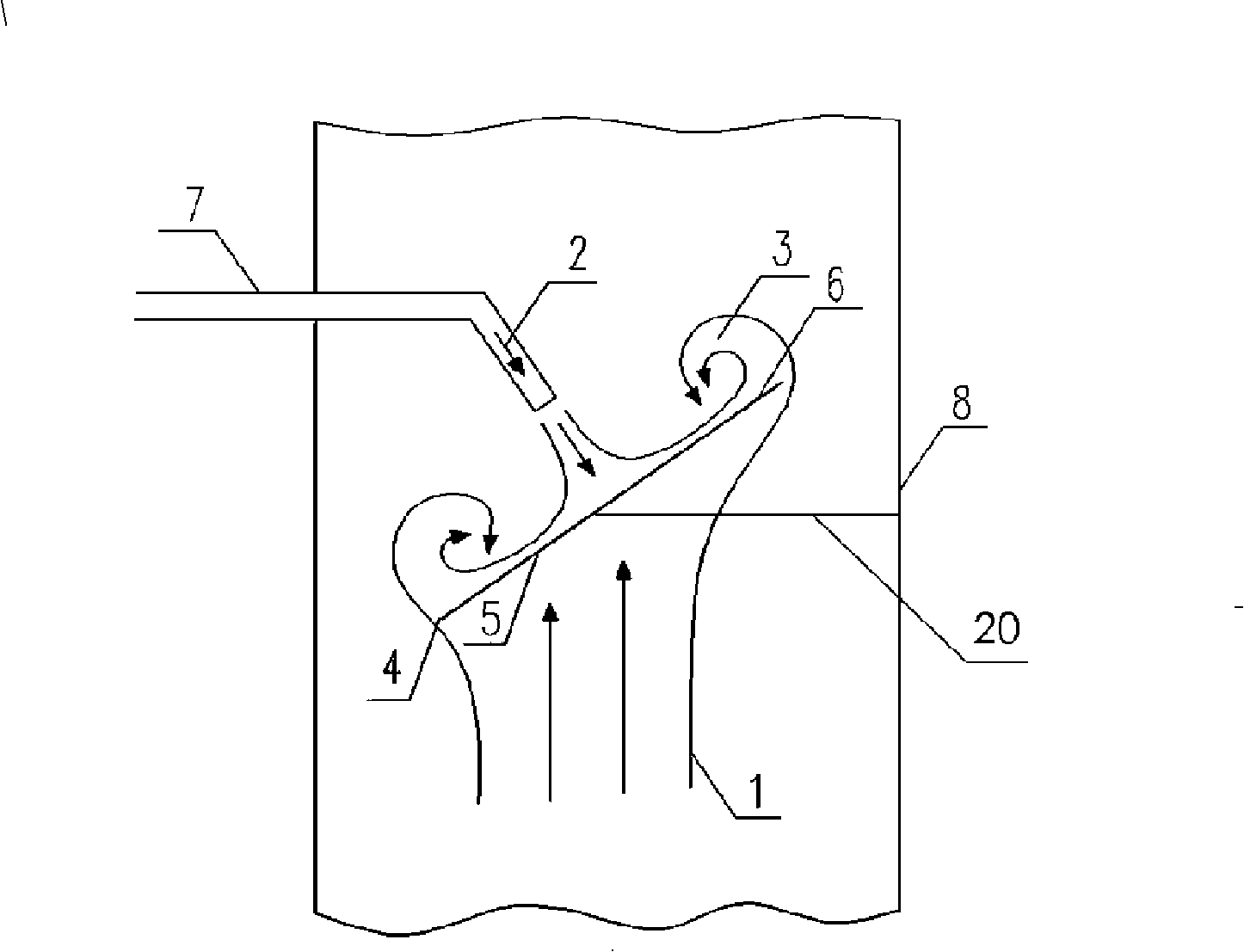

[0031] Embodiment one sees figure 1 As shown, this flue gas denitrification vortex mixer includes a mixing element placed in the flue 8 and a reducing agent nozzle 7 inserted into the flue. It is fixedly connected with the inner wall of the flue, the backflow surface 6 of the mixing element is a plane, the angle between the backflow surface and the flow direction of the flue gas is 10°-90°, and it is facing the nozzle of the reducing agent nozzle 7, but not in contact with The nozzles of the reducing agent nozzles are in contact with each other, and the flow surface 5 of the mixing element faces the flow direction of the fluid.

[0032] The plane of the sheet-like mixing element 4 may be circular, elliptical, rectangular, trapezoidal or other polygonal shapes adapted to the cross-sectional shape of the flue. The mixing element is made of carbon steel or other materials resistant to high temperatures of 450°C. The diameter of the mixing element does not exceed 80% of the cros...

Embodiment 2

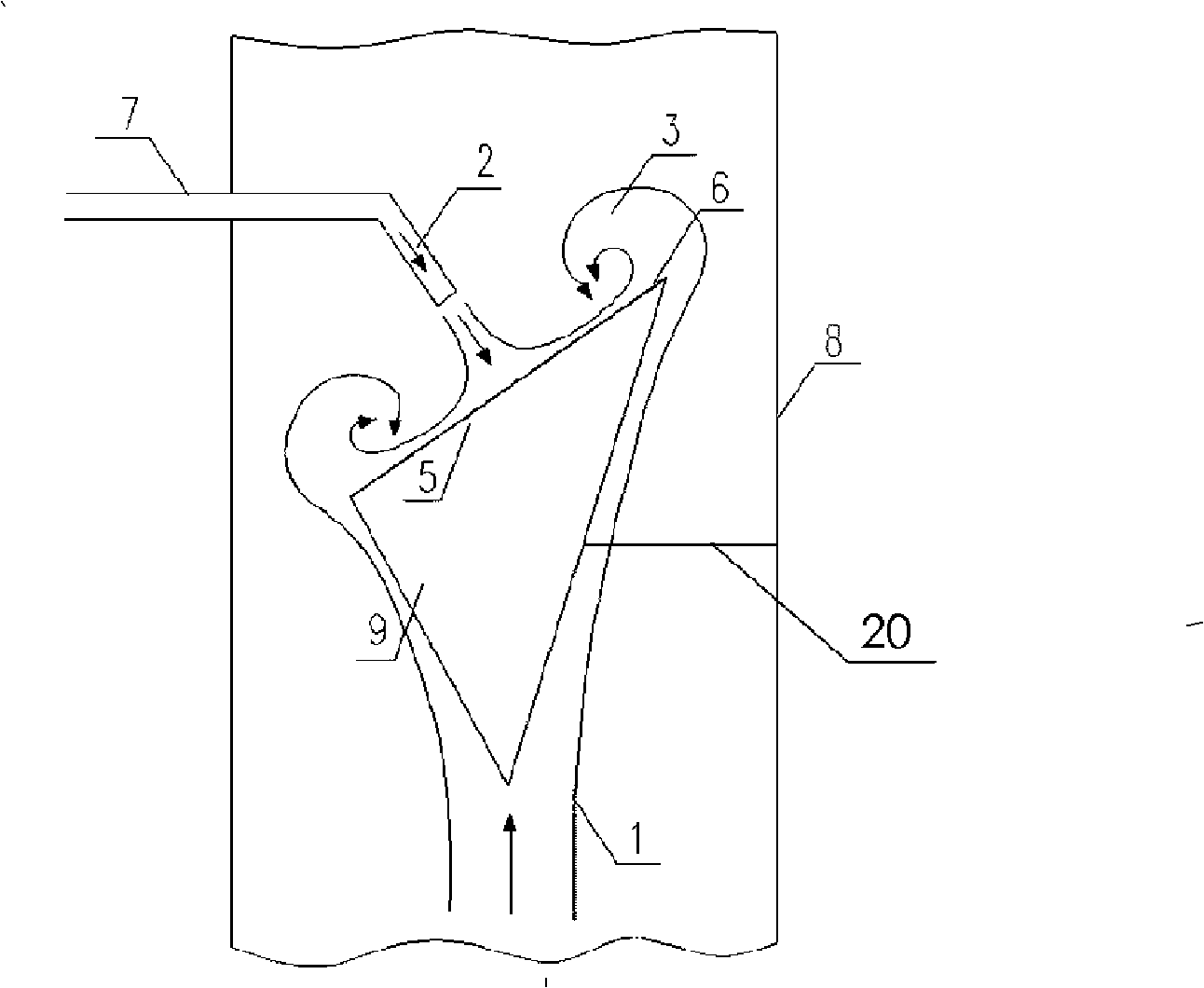

[0034] Embodiment two see figure 2 As shown, the difference from Example 1 is that the flue gas denitrification vortex mixer uses a conical mixing element 9, and the above-mentioned conical mixing element 9 is a right conical, oblique conical, elliptical conical, equilateral pyramid or unequal pyramid The bottom surface of the cone is the reverse flow surface, and the tip of the cone faces the flow direction of the flue gas 1.

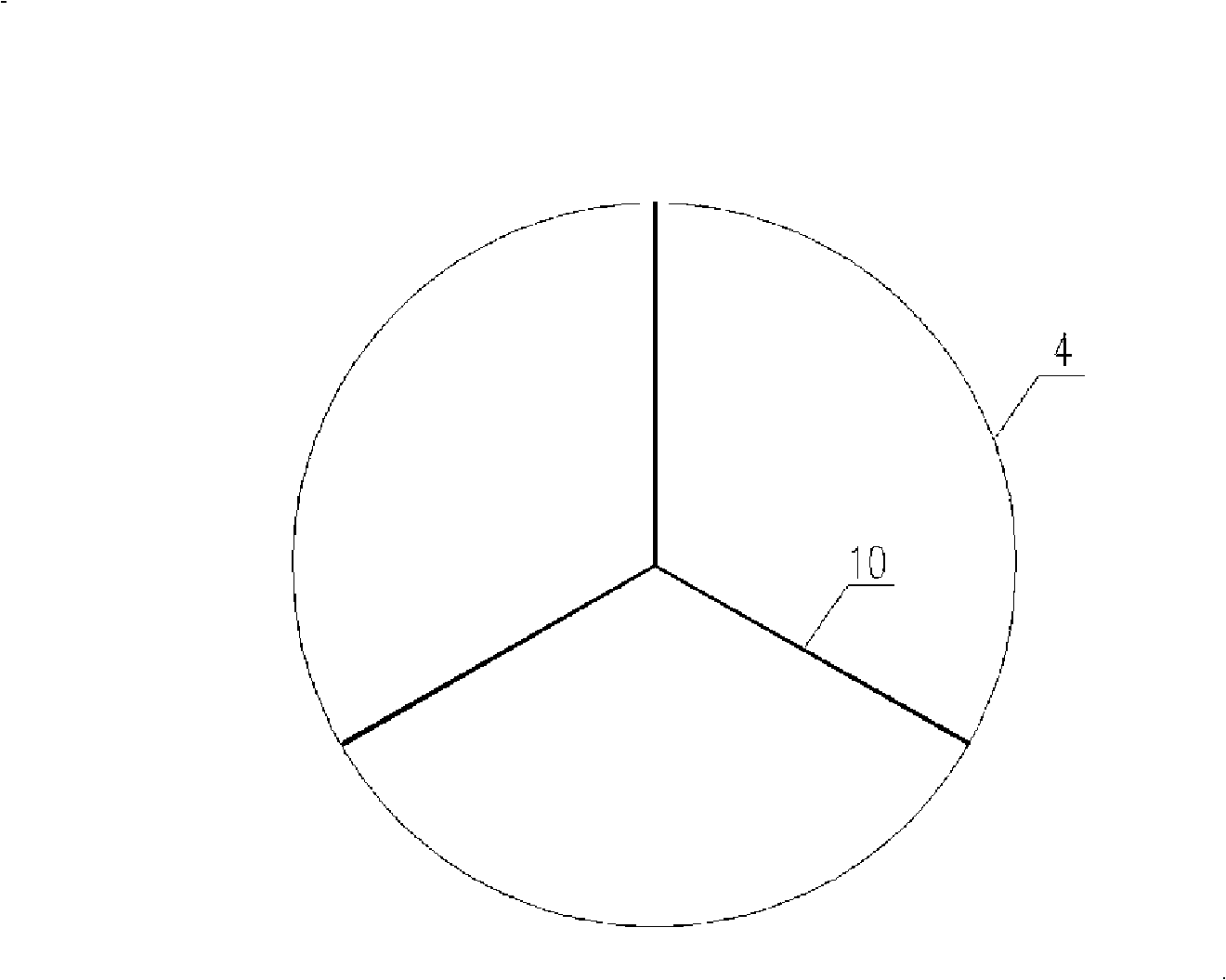

[0035] see image 3 , the backflow surface of the above-mentioned mixing element 4 may be fixed with a radial partition plate 10 that divides the surface 3-n into equal parts. The divider acts as a flow guide, which can make the air distribution more even.

[0036] For regularly shaped mixing elements, the reducing agent, ammonia, can be sent to the center of the backflow surface, which is at the center of gravity of the plane. For mixing elements with irregular shapes, such as unequal triangular pyramids, trapezoids or similar polygonal mixing ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com