Equipment and process for casting multi-branch steel ingot with vacuum spill method and liquid steel

A technology of vacuum casting and molten steel, which is used in foundry equipment, metal processing equipment, and the control of molten metal pouring from the ladle. The effect of shortening casting time, simplifying operation and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 6

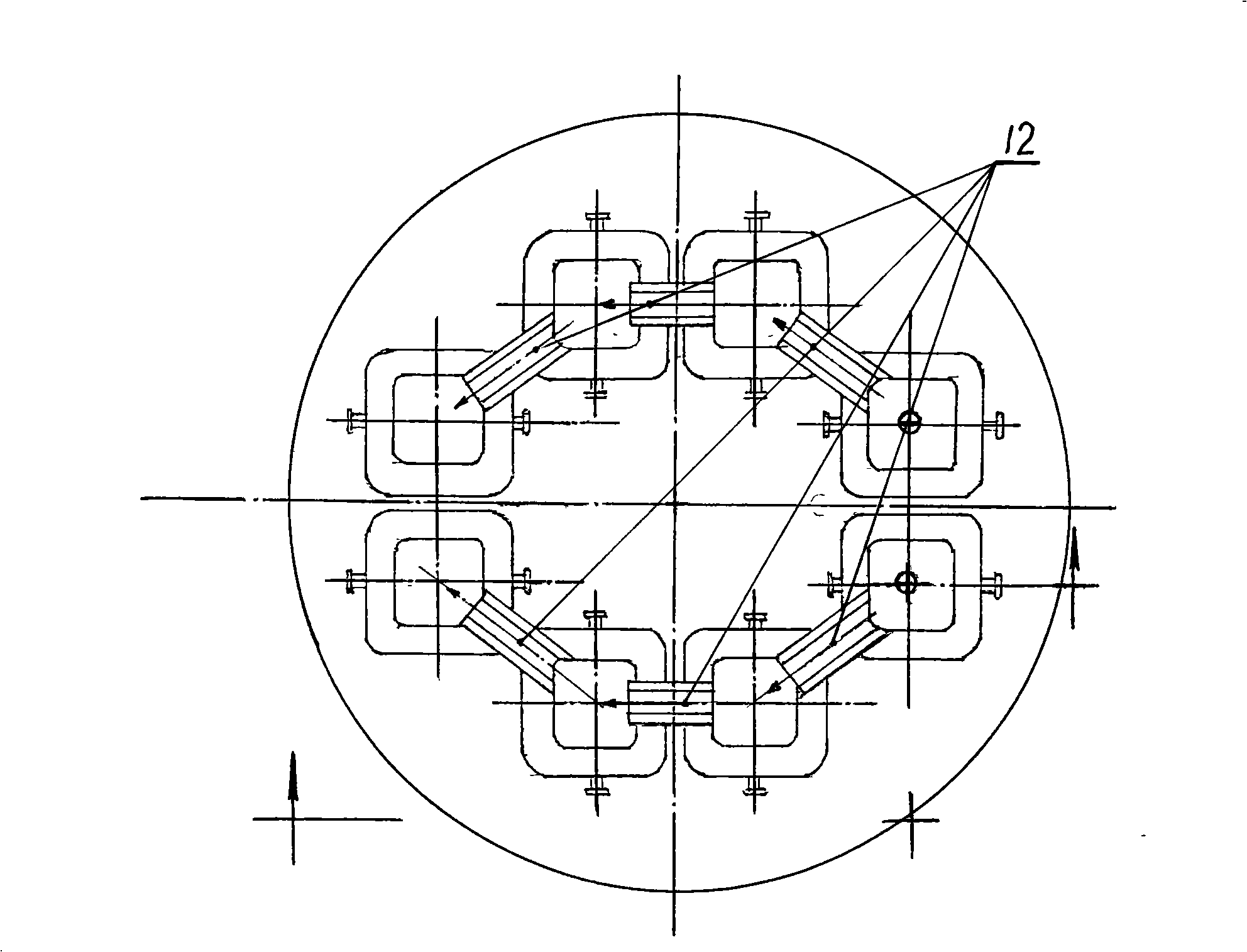

[0171] Embodiment 6 is the process plan layout diagram of the vacuum chamber ingot mould, insulation cap, one-way groove, and sliding nozzle center when casting 4 12-ton flat ingots in scheme one or scheme two.

Embodiment 1

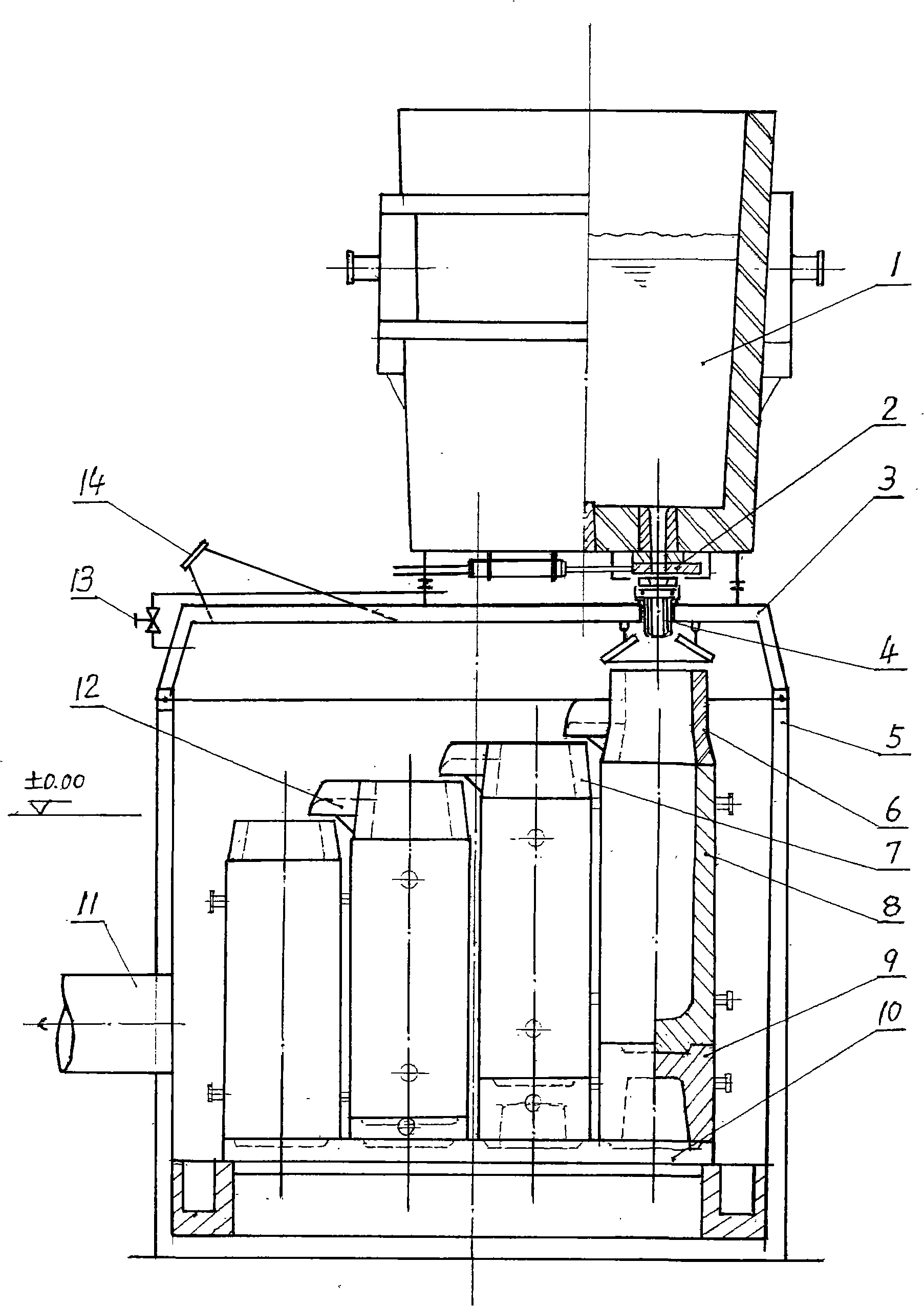

[0172] Embodiment 1: As shown in Figure 5 of the description:

[0173] The first method is to cast two large steel ingots of about 60-80 tons by the single-strand one-way overflow method, and set a one-way groove on the insulation cap of the first ingot mold, and use a VD sliding nozzle ladle of about 125-165 tons of molten steel to continuously When casting 2 large steel ingots, when the cap opening of the second steel ingot reaches a certain height before the specified height, close the sliding nozzle and use 2 casting cycles.

[0174] Such as VD ladle is smaller. It is also very convenient to cast two smaller steel ingots, and of course the inner diameter and height of the vacuum ingot casting chamber can also be smaller.

[0175] This example is suitable for use in the heavy machinery industry.

Embodiment 2

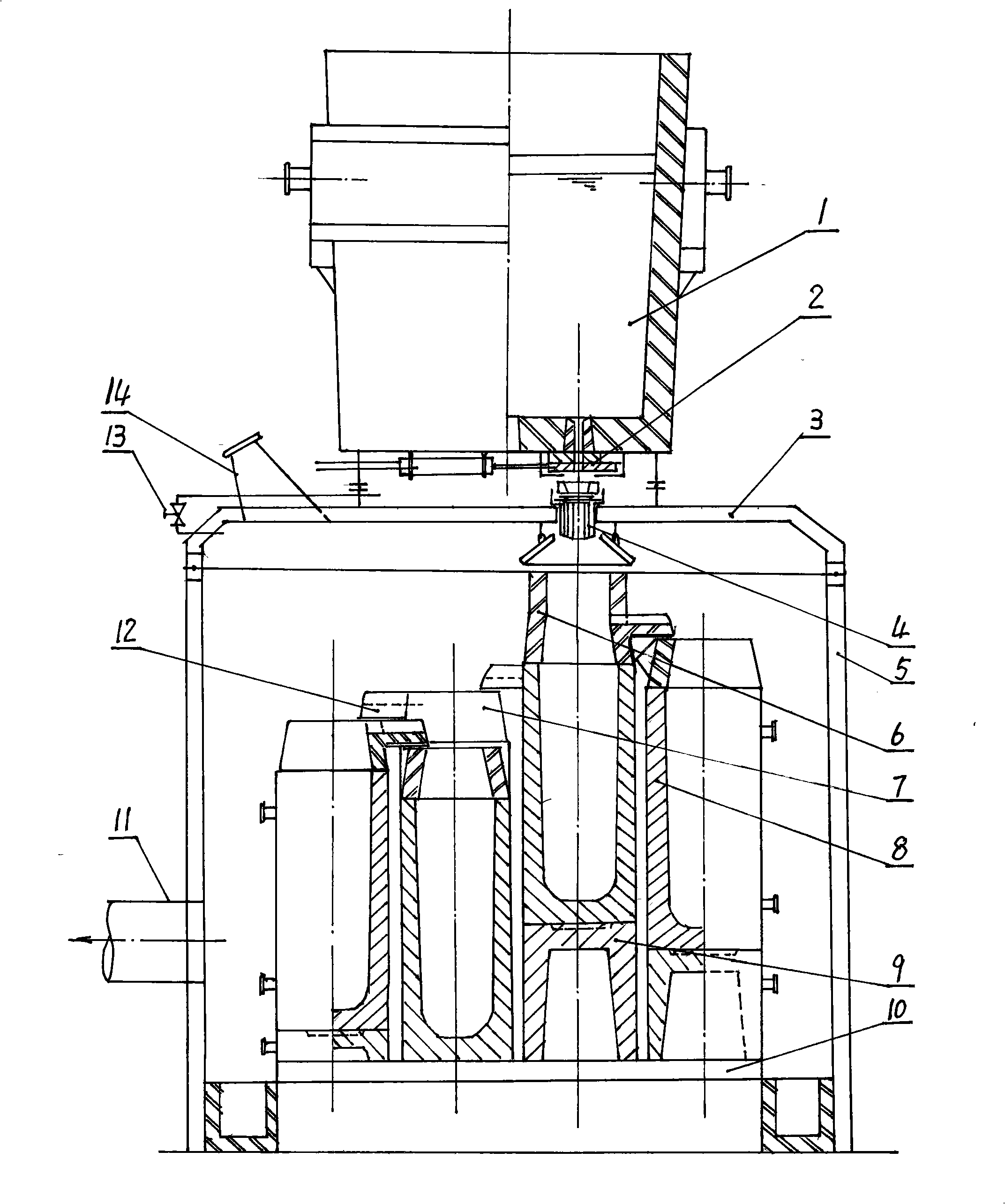

[0176] Embodiment 2: as shown in the accompanying drawings 7 (a) and 7 (b) of the description:

[0177] Accompanying drawing 7 (a) is the third scheme double-strand balance overflow method to cast 3 large steel ingots of about 45 tons, and the first ingot mold insulation cap is provided with 2 balance tanks with an included angle of 60°, using about 140 tons of molten steel The VD sliding nozzle ladle continuously casts 3 large steel ingots, one in the first casting cycle, the flow rate of molten steel in the second casting cycle is doubled, and two large steel ingots are cast at the same time, before the cap mouth of the second and third ingot reaches the specified height For a moment, close the sliding nozzle. No horns.

[0178] Accompanying drawing 7 (b) is scheme 1 single-strand unidirectional overflow method casts 3 large steel ingots of about 45 tons, the first and second ingot mold insulation caps are respectively provided with a unidirectional groove, and two unidirec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com