Preparation method for astragaloside

A technology of astragaloside IV and Astragalus membranaceus, applied in the field of preparing high-yield and high-purity astragaloside IV, which can solve the problems of low yield and achieve the effects of low production cost, high purity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

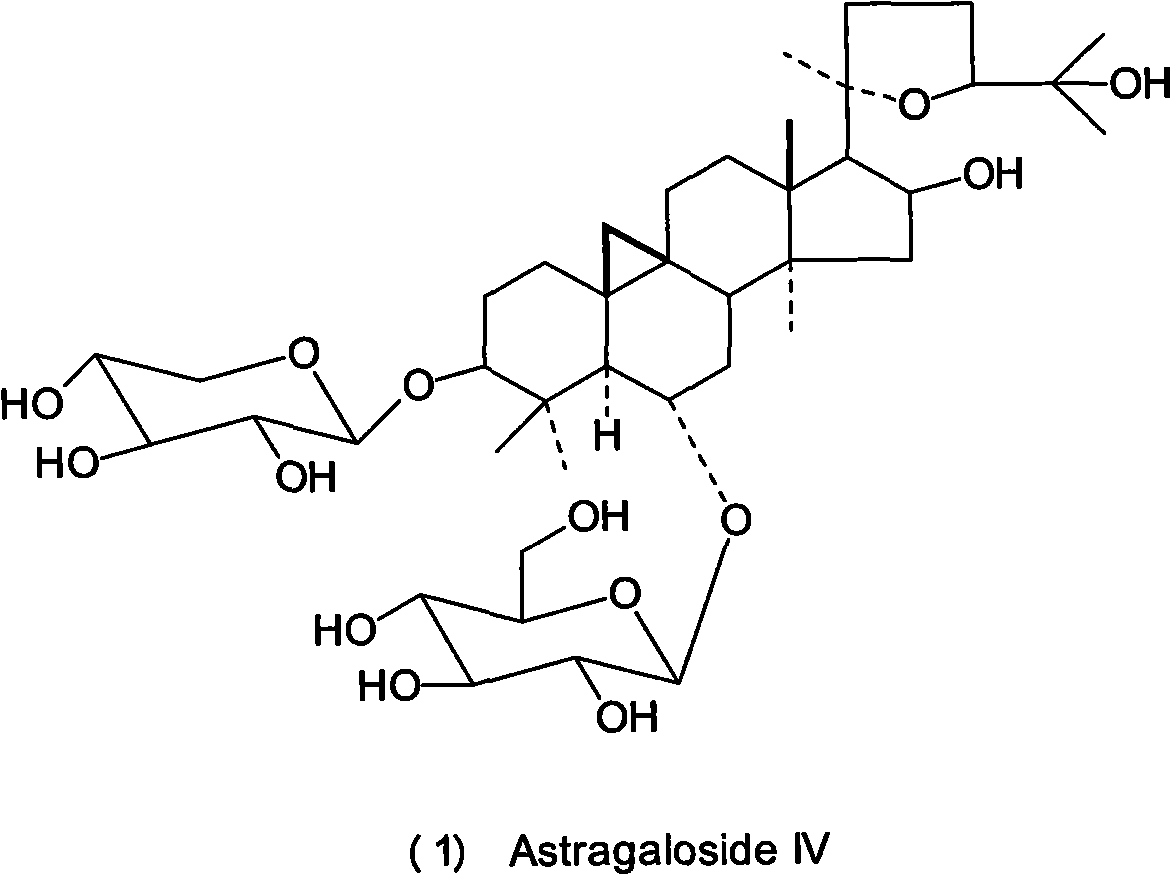

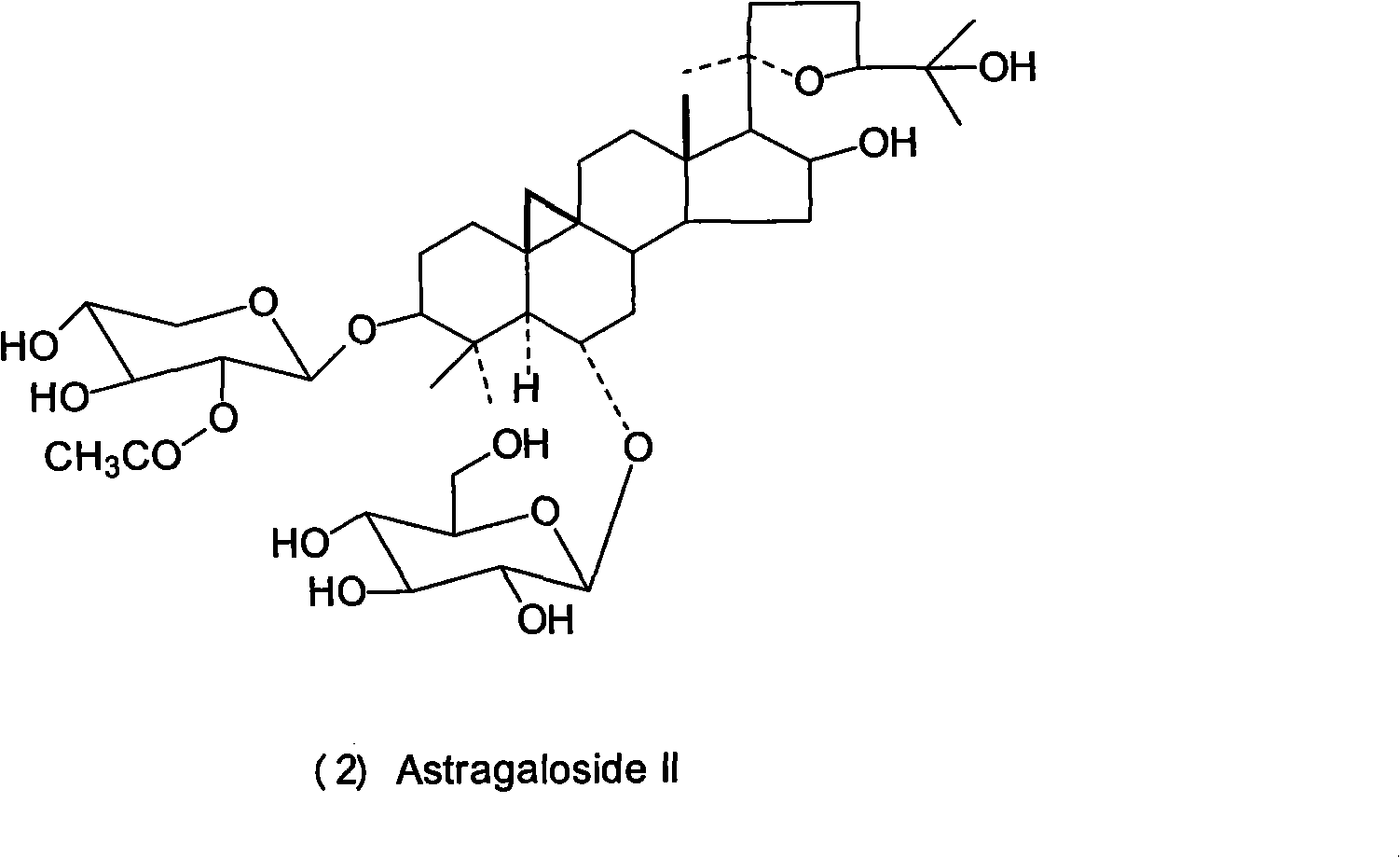

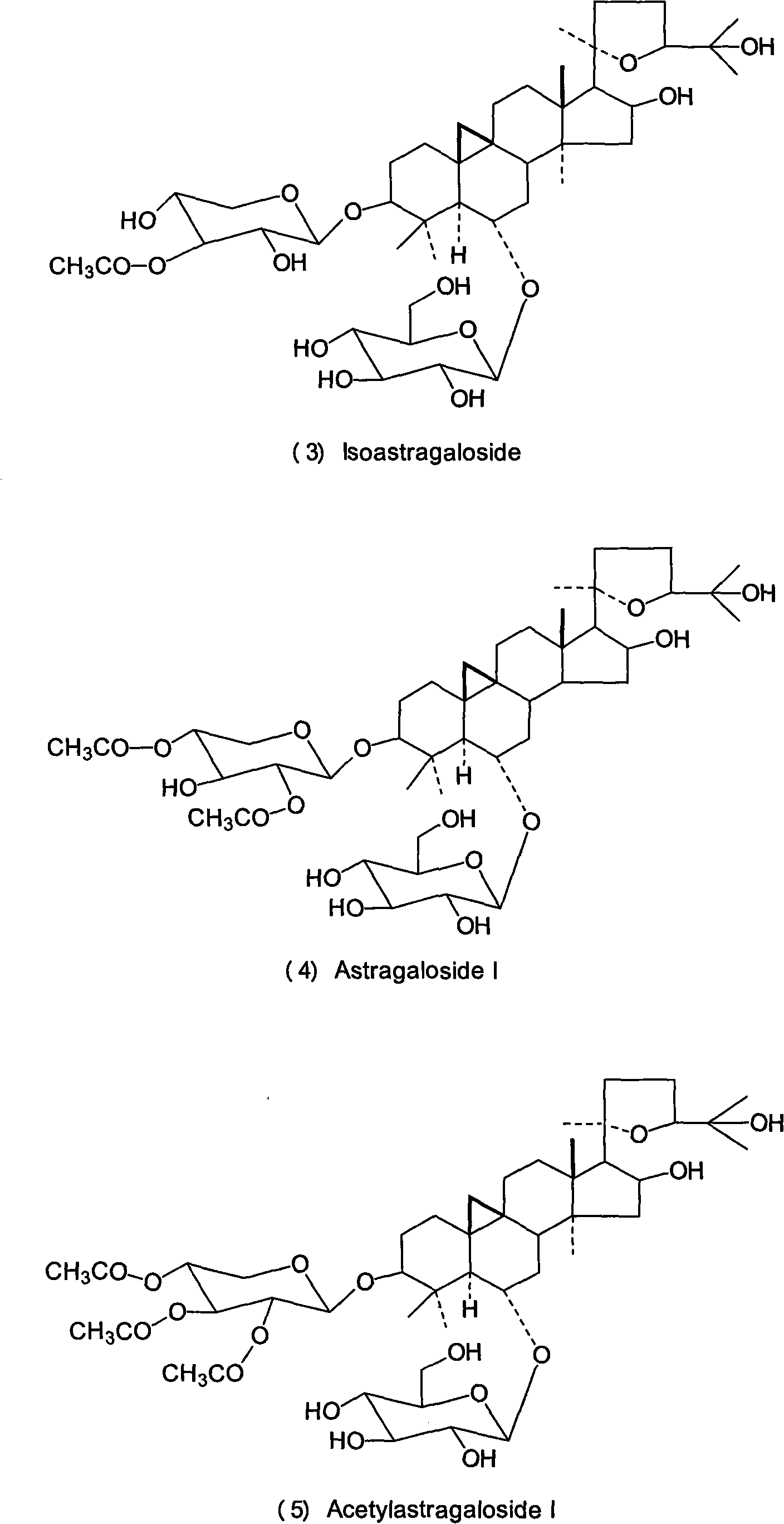

Image

Examples

Embodiment 1

[0040] After crushing 1 kg of Astragalus root, heat and reflux with water to extract 3 times, add 10 times of water to reflux for 1 hour for the first time, and add 8 times of water to reflux for 0.5 hours for the second and third times. Combine the extracts, add Ca(OH) 2 Appropriate amount of solid powder to make Ca(OH) 2Saturated solution, placed at room temperature for 16 hours, centrifuged, the supernatant adjusted to pH 8 with dilute hydrochloric acid solution, added to HPD100 macroporous adsorption resin, washed with 10 liters of deionized distilled water to remove sugars and salts, and then washed with 5 liters of 40% alcohol washes away impurities. Then, astragaloside IV was eluted with 3 liters of 80% alcohol, and the eluate was concentrated to a small volume, centrifuged to obtain astragaloside IV, and recrystallized with dilute ethanol to obtain 1.9 g of astragaloside IV, with a content of 98%.

Embodiment 2

[0042] After crushing 1 kg of Astragalus root, heat and reflux extraction with water for 3 times, add 12 times of water for reflux for 1.5 hours for the first time, and add 10 times of water for 1 hour for the second and third times. Combine the extracts, add Ca(OH) 2 Appropriate amount of solid powder to make Ca(OH) 2 Saturated solution, placed at room temperature for 20 hours, centrifuged, the supernatant adjusted to pH 8 with dilute hydrochloric acid solution, added to D101 macroporous adsorption resin, washed with 14 liters of deionized distilled water to remove sugars and salts, and then washed with 5 liters of 40% alcohol washes away impurities. Then, astragaloside IV was eluted with 3 liters of 80% alcohol, and the eluate was concentrated to a small volume, centrifuged to obtain astragaloside IV, and recrystallized with dilute ethanol to obtain 2.1 g of astragaloside IV, with a content of 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com