Adhesive, reflecting film, pad pasting glass or slice brick containing the adhesive

A technology of reflective film and adhesive glue, applied in the field of adhesive glue, can solve the problems of poor water resistance and impermeability of pressure-sensitive adhesive, inability to paste the pressure-sensitive adhesive, short service life, etc. The effect of good social environmental protection, energy saving and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

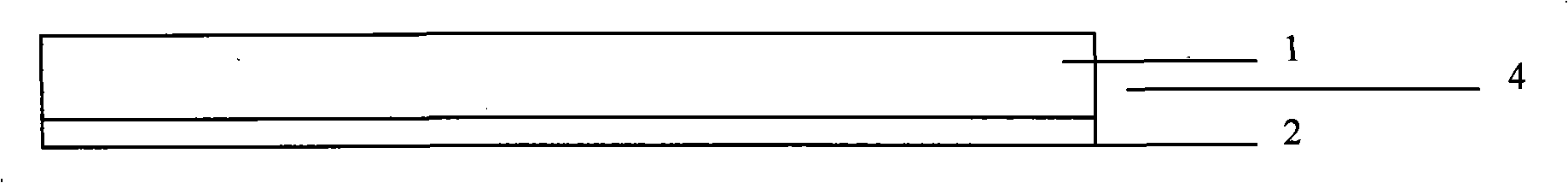

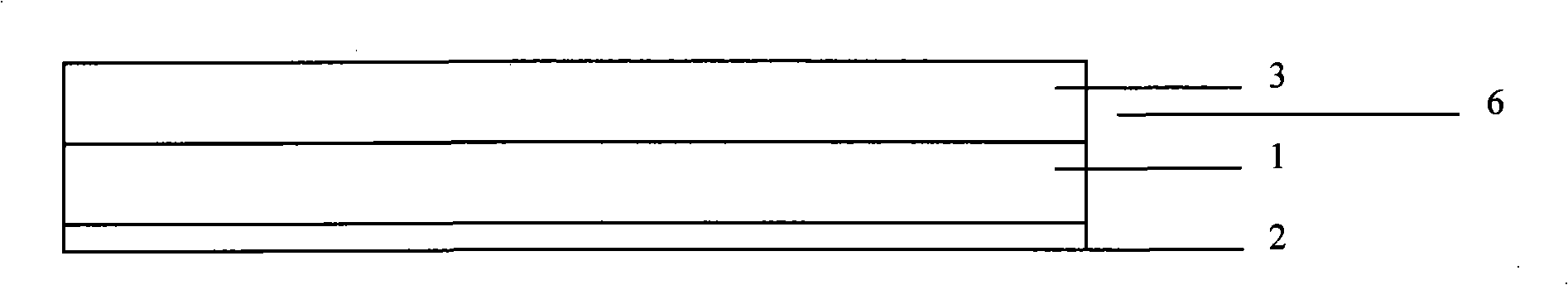

Image

Examples

Embodiment 1

[0039] A kind of adhesive, which is mixed and stirred by the following components by weight ratio:

[0040] 100 parts of epoxy resin 50 parts of anti-yellowing epoxy resin

[0041] 75 parts of porcelain clay powder above 600 mesh, 1 part of cellulose (HPMC).

Embodiment 2

[0043] A kind of adhesive, which is mixed and stirred by the following components by weight ratio:

[0044] 100 parts of epoxy resin 50 parts of anti-yellowing epoxy resin

[0045] 120 parts of quartz powder above 600 mesh, 6 parts of cellulose (HPMC).

Embodiment 3

[0047] A kind of adhesive, which is mixed and stirred by the following components by weight ratio:

[0048] 100 parts of epoxy resin 50 parts of anti-yellowing epoxy resin

[0049] 120 parts of quartz powder above 600 mesh, 4 parts of cellulose (HPMC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com