Efficient seat heating cushion

A seat heating and high-efficiency technology, applied in the field of auto parts, can solve the problems of poor durability and stability of seats, affect the environmental protection of the whole vehicle, and failure of electric heating function, etc., achieve heat balance, excellent heat insulation, and ensure high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

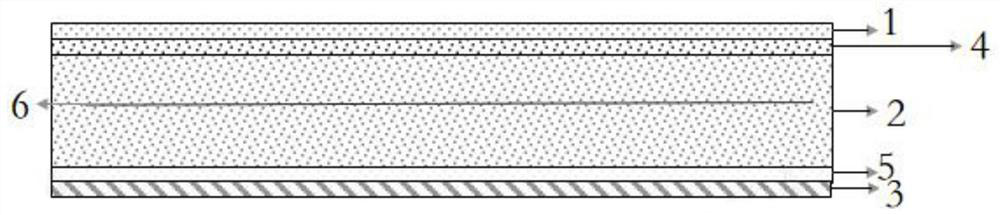

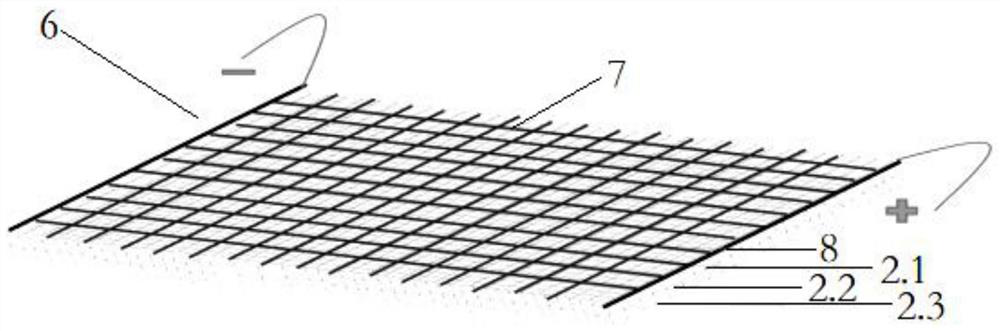

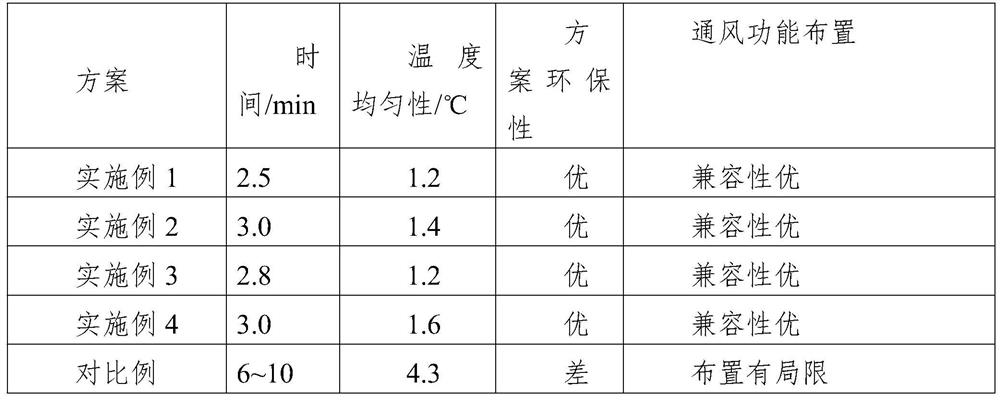

[0025] This embodiment is used for the main driver of a certain car model. The heating pad is from top to bottom: fabric layer 1 (the seat fabric is usually two layers, cortex layer and base fabric layer); heat-conducting silicone adhesive layer (heat-conducting adhesive layer 4) 3D fabric layer (intermediate layer 2) containing electric heating wire; thermal insulation adhesive layer 5 and thermal insulation layer 3, thermal insulation layer 3 is made of breathable non-woven fabric impregnated with airgel by sol-gel method. 3 grams of heat insulation layer weighs 200g / m 2 , the airgel powder mass fraction is 60%.

[0026] The material of fabric layer 1 is perforated polyvinyl chloride artificial leather, the thickness of the material is 1.0mm, and the total weight is 760g / m 2 , the basis weight is 200g / m 2 , in which aluminum-based heat-conducting agent is added to the PVC skin layer, polyester yarn with high thermal conductivity is selected as the base fabric yarn, and the...

Embodiment 2

[0029] This embodiment is used for the main driver of a certain car model. The heating pad is from top to bottom: fabric layer 1 (the seat fabric is usually two layers, cortex layer and base fabric layer); heat-conducting silicone adhesive layer (heat-conducting adhesive layer 4) 3D fabric layer 3 (middle layer 2) containing electric heating wire; thermal insulation adhesive layer 5 and thermal insulation layer 3, thermal insulation layer 3 is made of air-permeable non-woven fabric impregnated with airgel by sol-gel method. 3 grams of heat insulation layer weighs 250g / m 2 , the airgel powder mass fraction is 20%.

[0030]Fabric layer 1 is made of perforated polyurethane synthetic leather with a thickness of 0.7mm and a total weight of 480g / m 2 , the basis weight is 340g / m 2 , in which aluminum-based thermal conductive agent is added to the polyurethane synthetic leather layer, polyester yarn with high thermal conductivity is selected as the base fabric yarn, and the polyuret...

Embodiment 3

[0033] This embodiment is used for the main driver of a certain car model. The heating pad is from top to bottom: fabric layer 1 (the seat fabric is usually two layers, cortex layer and base fabric layer); heat-conducting silicone adhesive layer (heat-conducting adhesive layer 4) 3D fabric layer (intermediate layer 2) containing electric heating wire; thermal insulation adhesive layer 5 and thermal insulation layer 3, thermal insulation layer 3 is formed by impregnating airgel through sol-gel method for breathable non-woven fabric. 3 grams of heat insulation layer weighs 300g / m 2 , the airgel powder mass fraction is 30%.

[0034] The material of fabric layer 1 is perforated microfiber leather, the material thickness is 1.2mm, and the total weight is 690g / m2. Aluminum-based heat-conducting powder is added to the microfiber leather, and the microfiber leather is evenly distributed 1.0mm, with 6*6 holes.

[0035] The thickness of the middle layer 2 is 8mm, and the weight is 400g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com