CFRP/aluminum alloy hot forming quenching aging co-solidification integrated forming method

A quenching aging, aluminum alloy technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problem of inability to achieve sufficient solid solution of alloying elements in aluminum alloy sheets, failure to meet the rapid integrated forming of composite structures, and reduce the utilization of thermoforming molds efficiency and other issues, to achieve the effect of omitting the bonding process, avoiding thermal distortion, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

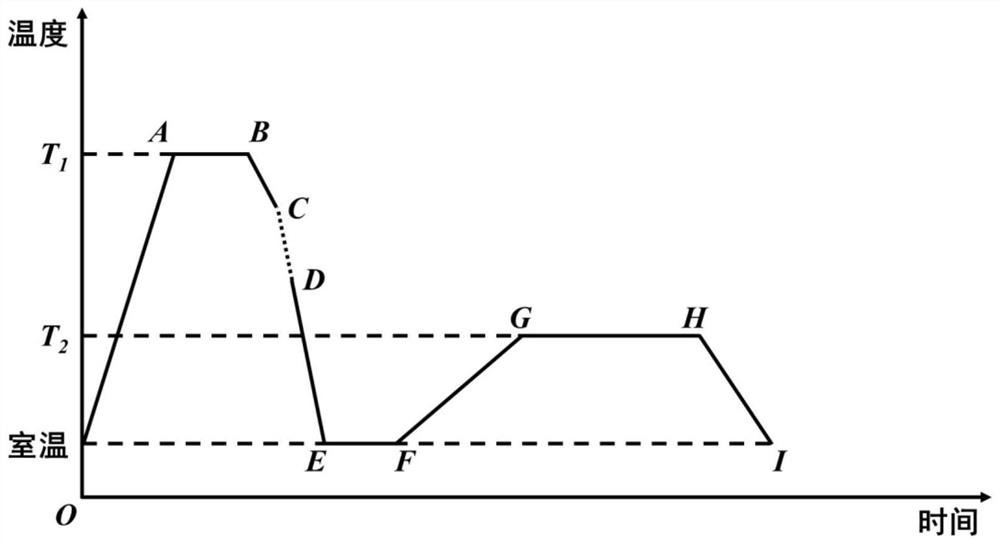

[0040]This example provides a CFRP / aluminum alloy composite structure composed of aluminum alloy 6063T1 with an aging time of about 2 hours and conventional cured prepreg USN10000 (produced by Weihai Guangwei Composite Materials Co., Ltd.). The temperature change curve adopted by the aging-co-curing integrated forming method is as follows: figure 1 As shown, the process mainly includes the following stages:

[0041] (1) The A-B section is the solid solution stage. The aluminum alloy is placed in a heating furnace and heated at 450°C (T 1 ) under the condition of heating for 180min, so that the precipitated phase in the alloy is fully dissolved;

[0042] (2) The B-C section is the transfer stage, and the aluminum alloy sheet is quickly transferred to the water-cooled mold to avoid a sharp drop in the temperature of the sheet and affect its formability;

[0043] (3) The C-D section is the forming stage, and the mold is formed within 5s. The deformation resistance and springbac...

Embodiment 2

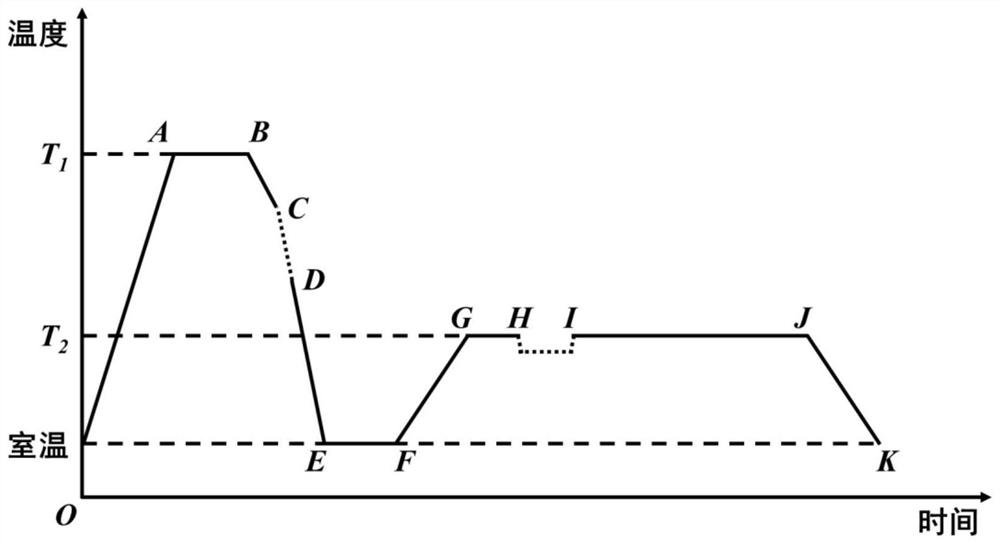

[0051] This example provides a CFRP / aluminum alloy composite structure composed of aluminum alloy 2219 with an aging time of more than 2 hours and a fast-curing prepreg CFSJ-1000Z (produced by Shandong Jiangshan Fiber Technology Co., Ltd.). The temperature change curve adopted by the aging-co-curing integrated forming method is as follows: figure 2 As shown, the process mainly includes the following stages:

[0052] (1) The A-B section is the solid solution stage. The aluminum alloy is placed in a heating furnace and heated at 575°C (T 1 ) under the condition of heating for 30min, so that the precipitated phase in the alloy is fully dissolved;

[0053] (2) The B-C section is the transfer stage, and the aluminum alloy sheet is quickly transferred to the water-cooled mold to avoid a sharp drop in the temperature of the sheet and affect its formability;

[0054] (3) The C-D section is the forming stage, and the mold is formed within 5s. The deformation resistance and springbac...

Embodiment 3

[0064] This example provides a CFRP / aluminum alloy composite structure composed of aluminum alloy 6061 with an aging time of more than 2 hours and a fast-curing prepreg CFSJ-1000Z (produced by Shandong Jiangshan Fiber Technology Co., Ltd.). The temperature change curve adopted by the aging-co-curing integrated forming method is as follows: figure 2 As shown, the process mainly includes the following stages:

[0065] (1) Section A-B is the solid solution stage. Put the aluminum alloy in a heating furnace and heat it at 525°C for 60 minutes to fully dissolve the precipitated phase in the alloy;

[0066] (2) The B-C section is the transfer stage, and the aluminum alloy sheet is quickly transferred to the water-cooled mold to avoid a sharp drop in the temperature of the sheet and affect its formability;

[0067] (3) The C-D section is the forming stage, and the mold is formed within 5s. The deformation resistance and springback of the aluminum alloy sheet are small at high tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com