Method for producing titanium alloy artificial hip joint with abrasion-proof ceramic coat

A technology of wear-resistant ceramics and manufacturing methods, which is applied in the direction of hip joints, joint implants, joint implants, etc., can solve the problems of low bonding strength between the film and the substrate, poor wear resistance and durability, and poor mechanical bearing capacity. Achieve the effect of avoiding galvanic corrosion, prolonging service life and good friction reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

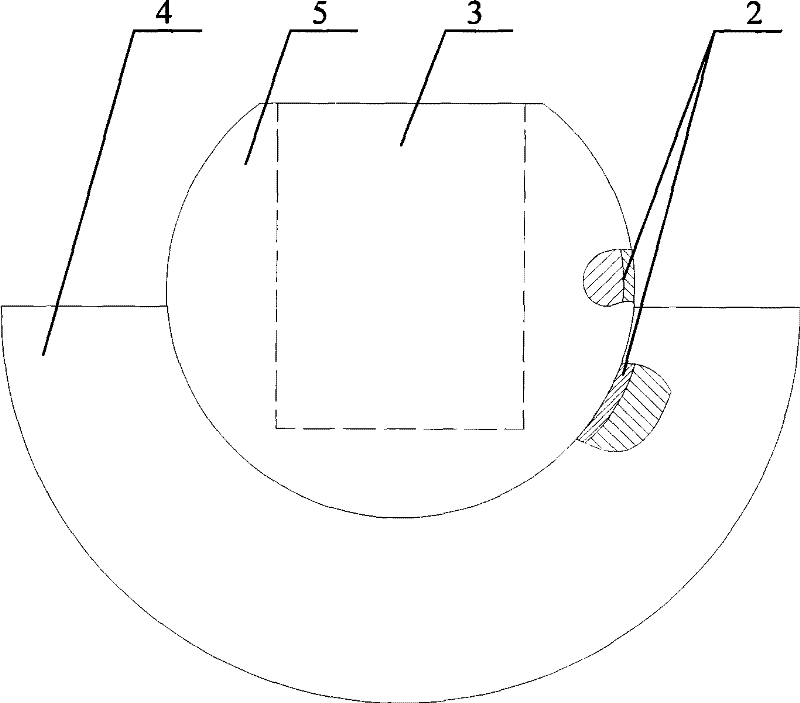

[0008] Specific implementation mode one: combine figure 1 This embodiment is described. This embodiment includes a titanium alloy femoral head 5 and a titanium alloy hip cup 4 mated with it. The hip joint also includes a wear-resistant ceramic coating 2, and the wear-resistant ceramic coating 2 is coated on titanium On the spherical surface of the alloy femoral head 5 and on the surface of the titanium alloy hip cup 4, a cylindrical groove 3 is opened on the upper end surface of the titanium alloy femoral head 5 to cooperate with the stem.

specific Embodiment approach 2

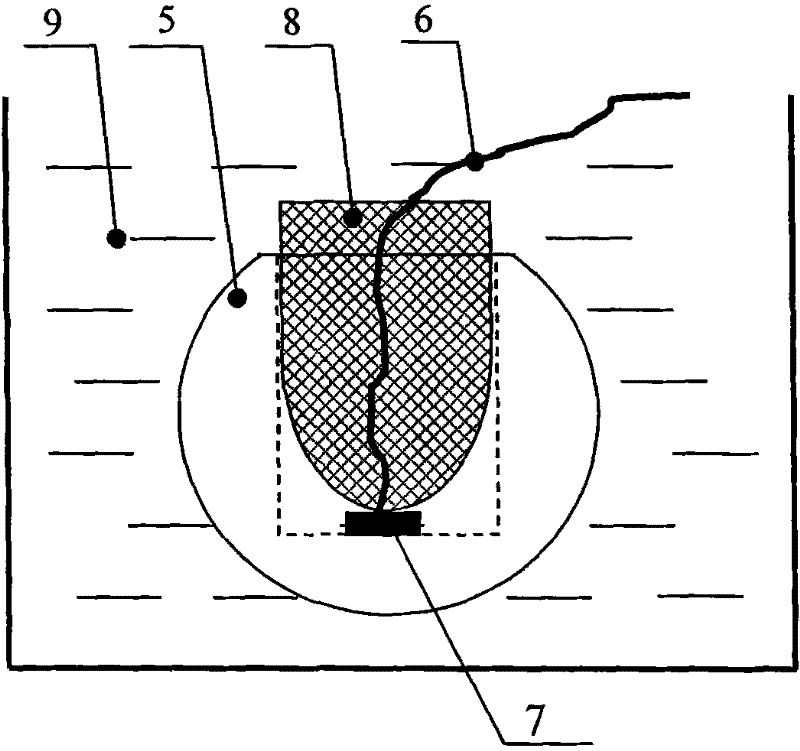

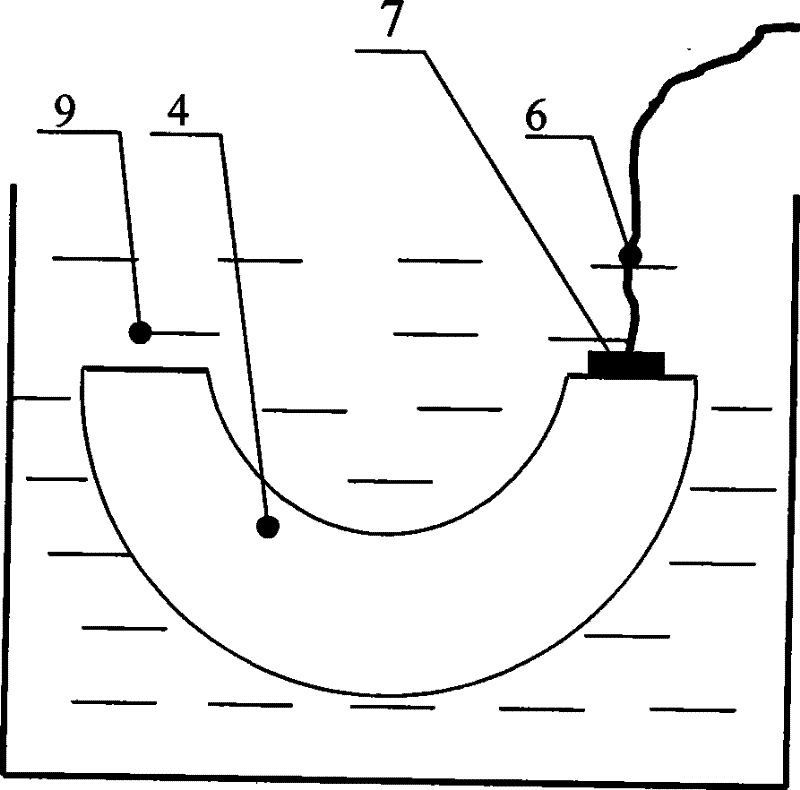

[0009] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment, the manufacture method of the titanium alloy artificial hip joint with wear-resistant ceramic coating of this embodiment is finished like this: Step 1, the titanium alloy femoral head 5 and titanium alloy hip cup 4 of pre-ceramization treatment are respectively Grinding and polishing to the mirror surface, the two clamps 7 are respectively installed and clamped on the bottom surface of the cylindrical groove 3 on the upper end surface of the titanium alloy femoral head 5 and on the titanium alloy hip cup 4, and the cylindrical groove on the upper end surface of the titanium alloy femoral head 5 is fixed. Shape groove 3 is filled with insulation shielding object 8, and an anode contact wire 6 is embedded in insulation shield object 8 simultaneously, and anode contact wire 6 is connected with fixture 7 on the bottom surface of cylindrical groove 3, and another anode contacts Th...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 This embodiment is described. The difference between this embodiment and the second embodiment is that the clamp 7 in the first step of this embodiment is made of aluminum alloy or titanium alloy. The fixture is in close contact with the titanium alloy femoral head 5 and the titanium alloy hip cup 4, thereby avoiding contact point ablation due to poor contact under high-voltage discharge conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com