Method for recycling tungsten oxide powder dust from flue gas of calcining ammonium paratungstate and recovering device

A technology of tungsten oxide and ammonium paratungstate, which is applied in chemical instruments and methods, separation methods, climate change adaptation, etc., can solve problems such as easy pollution, low recovery rate, and high difficulty, and achieve reduction of production costs and environmental pollution, recycling High rate and utilization rate, the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

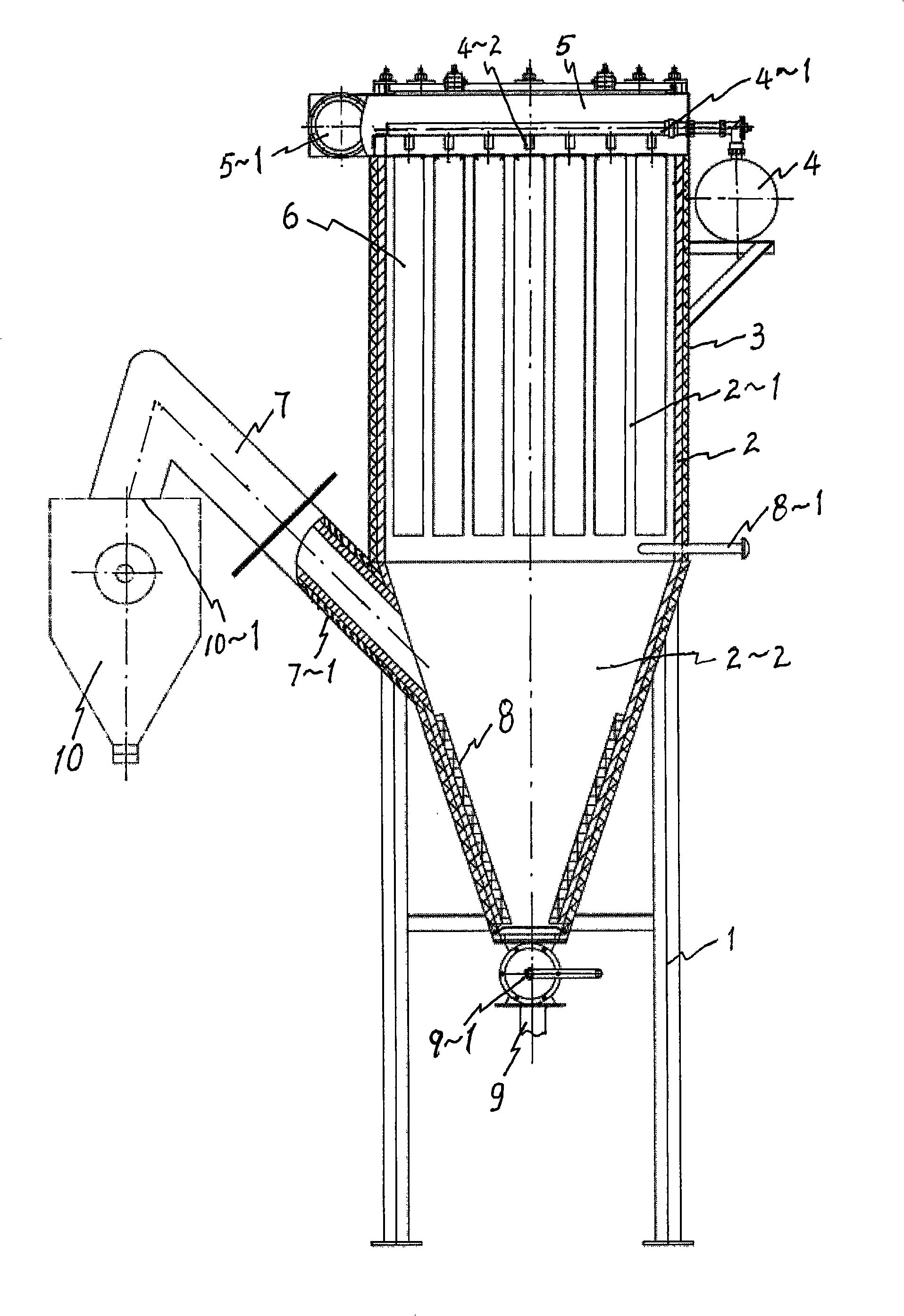

Embodiment 1

[0014] Example 1: Taking the dust collection device used in conjunction with the ammonium paratungstate calciner as an example, the total height of the device is 3740 mm, in which: the axial height of dust collection chambers 2 to 1 is 1620 mm, the axial section of the inner cavity is a rectangle with a side length of 1268 mm, and the ash hoppers 2 to 1 The height of 2 is 1520mm, the included angle is 60°, and the height of exhaust chamber 5 is 325mm; there are 48 dust collection chambers 2~1 made of Fluomes material, with a total filtration area of 36m 2 There are 6 dust collection bags (groups) and 2 electric heating plates 8 symmetrically, each with a surface area of 0.335m 2 , 40A, 6KW, maximum surface temperature 350°C, thermocouple 8-1 is a thermocouple used in conjunction with electric heating plate 8; the present embodiment sets a model at the outlet end of tail gas outlet 5-1 as 4-72№-4A- The 5.5KW induced draft fan ensures the stable operation of the dust collect...

Embodiment 2

[0015] Example 2: Taking the recovery of tungsten oxide dust from the flue gas produced by calcining ammonium paratungstate to produce yellow tungsten as an example, 100 tons of APT are successively added to the rotary tube electric furnace for calcining to produce yellow tungsten, and the flue gas passes through the inverted "V"-shaped flue gas pipe 7 Entering from the upper part of the ash hopper 2~2, there are 48 filters made of Fluomes material, with a total filtration area of 36m 2 , In the dust collection chamber 2~1 of the dust collection bag (group) 6 of model FMS9804, at a temperature of 100±5°C, the working negative pressure is -4500pa and the air volume is 3000m 3 Under the condition of / h, the tungsten-containing oxide dust in the flue gas is collected in the ash hopper of the dust collector; in this embodiment, the dust bag is automatically cleaned once by reverse pressure (pulse) every 10 minutes, and the cleaning The ash flow pressure is 0.35Mpa, and the clean...

Embodiment 3

[0016] Example 3: Taking the recovery of tungsten oxide dust from the flue gas produced by calcining ammonium paratungstate to produce blue tungsten as an example, 100 tons of APT are successively added to the rotary tube electric furnace for calcining to produce blue tungsten, and the flue gas passes through the inverted "V"-shaped flue gas pipe 7 Entering from the upper part of the ash hopper 2~2, there are 102 filters made of Fluomes material, with a total filtration area of 61m 2 In the dust collection chamber 2~1 of the dust collection bag (group) 6, the temperature is 100±5°C, the working negative pressure is -3500pa and the air volume is 3200m 3 Under the condition of / h, the tungsten-containing oxide dust in the flue gas is collected in the ash hopper of the dust collector; the remaining parameters are the same as in Example 2. In this embodiment, 200kg of dust-collecting materials are obtained in total; the tail gas after dust removal is washed with water to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com