Method for removing volatilization ingredients of synthetic rubber

A technology of synthetic rubber and volatile matter, which is applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., which can solve the problems of large equipment investment, many personnel, high energy consumption, etc., to reduce equipment investment and simplify Process, the effect of shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

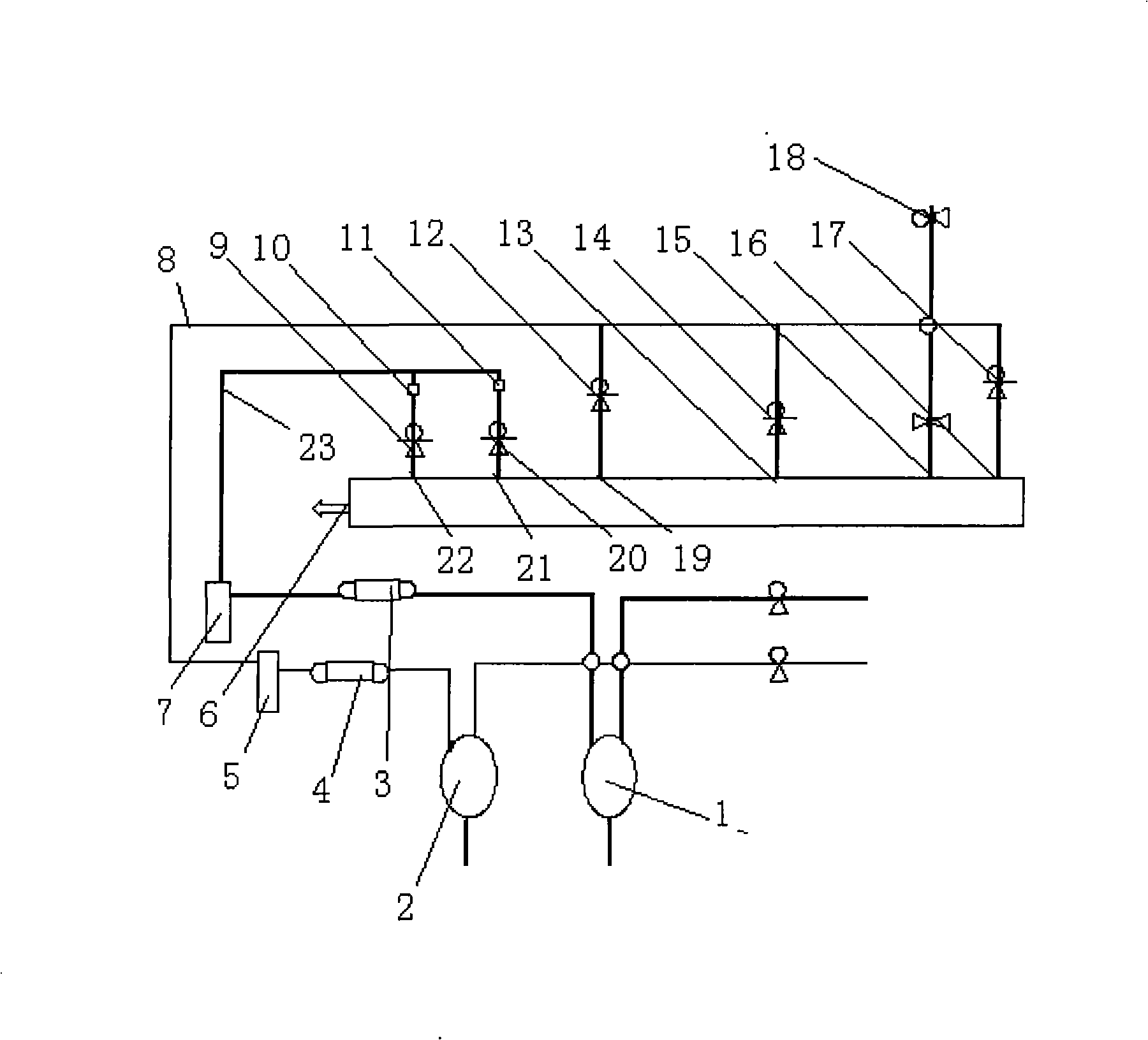

[0021] The structure of this process device is as follows (see figure 1 ): Twin-screw exhaust extruder 6 is divided into rear exhaust area 16, 2 # exhaust area 13, 3 # exhaust area 19, 4 # exhaust area 21, 5 # exhaust area 22 vacuum exhaust area, the glue pump 18 is connected to the glue inlet 15 between the rear exhaust area and 2# exhaust area through pipelines, and the outlet pipes of the rear exhaust area, 2# exhaust area and 3# exhaust area are respectively connected After the vacuum pumps 17, 14, 12 are connected to the intermediate tank 2 through the extraction solvent pipeline 8, the separator 5, and the cooler 4, the outlets of the 4# exhaust area and the 5# exhaust area are respectively connected to the vacuum pumps 20, 9, and then respectively connected to the solid state Transmitters 11 and 10 are connected to intermediate tank 1 through solvent removal pipeline 23 , separator 7 and cooler 3 .

Embodiment 2

[0023] This embodiment is a set of dry process rubber devolatilization pilot test device with an annual output of 100 tons of dry rubber. The quality is qualified, and a total of more than 500 kilograms of products have been obtained.

[0024] 1. Twin-screw vented extruder:

[0025] Model: Co-rotating twin-screw PE-50

[0026] Diameter: 50.5mm Aspect Ratio: 52

[0027] 2. Each exhaust port is connected to a vacuum pump, and the vacuum degree is controlled in sections.

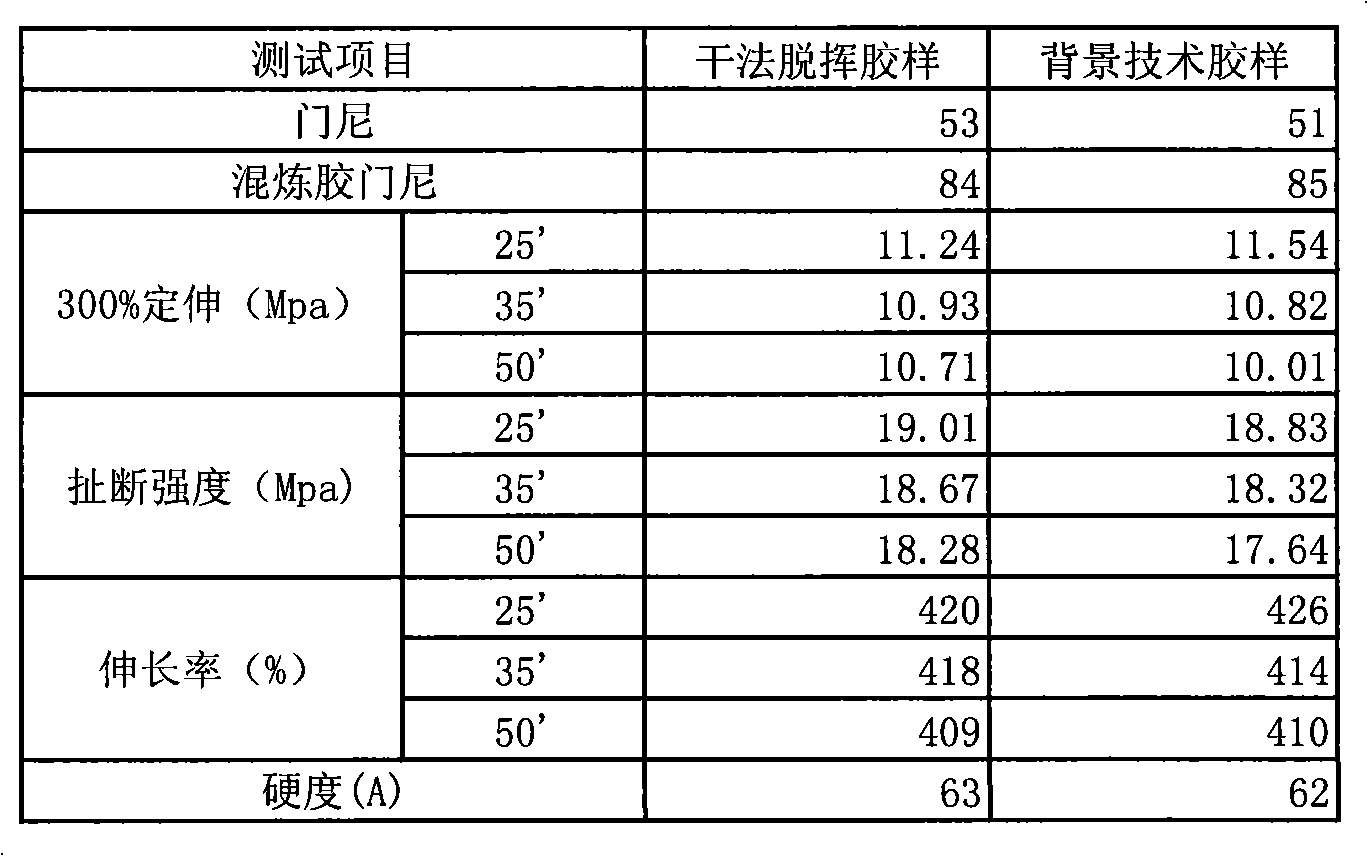

[0028] The rare earth glue (glue solid content above 18%) enters the twin-screw vented extruder, the residence time is 60-240 seconds, the processing temperature is 70-140 degrees, and the solvent is removed in a vacuum state, and the volatile content of the product can reach Below 1%, the performance of raw rubber and vulcanized rubber is equivalent to that of background craft products.

[0029] The twin-screw exhaust extruder has five vacuum exhaust chambers, and the exhaust port is connected with a vacuu...

Embodiment 3

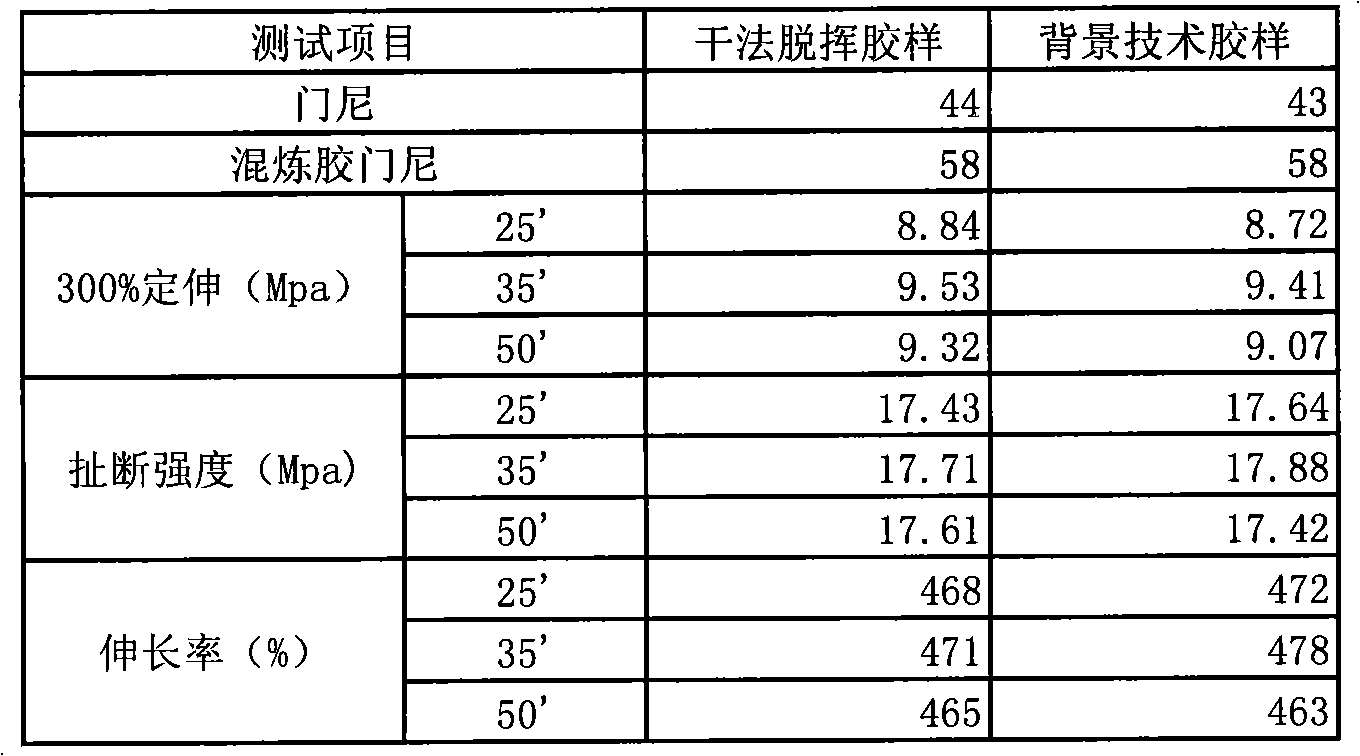

[0054] Devolatilization of nickel-based butadiene rubber in dry coagulation process

[0055] Since Ni is a variable-valence metal, it is required in the present invention that Ni in the rubber compound is low.

[0056] Glue Ni content: Ni / Bd is less than 1.5*10 -5 mol / mol

[0057] Glue solid content: more than 18%

[0058] The structure of the process equipment of the twin-screw exhaust type extruder is the same as that of Embodiment 1: including 5 control zones.

[0059] temperature control:

[0060] Table 1 Twin-screw vented extruder temperature control: unit is degree

[0061] Equipment location

[0062] Vacuum control:

[0063] Vacuum degree control: the unit is MPa

[0064] Table 2 Vacuum degree control of twin-screw vented extruder

[0065] Equipment location

[0066] Twin-screw exhaust type extruder Glue inlet pressure control: 0.4~1.5MPa

[0067] Twin-screw vented extruder screw speed control: 20-80 rpm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com