Photosensitive composition, photosensitive resin transfer film, and method for producing a photospacer, and substrate for a liquid crystal display device and liquid display device

A photosensitive resin and composition technology, applied in optics, optomechanical equipment, nonlinear optics, etc., can solve problems such as inability to maintain the uniformity of the liquid crystal layer, image inhomogeneity, large plastic deformation, etc., and achieve the elimination of display inhomogeneity , high quality image, high deformation recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The photosensitive resin layer is subjected to a preparation process described in detail later, so as to form an optical spacer with excellent deformation recovery ability and can maintain a uniform thickness of the element. By using the optical spacers, display unevenness in images is effectively prevented, particularly in a display device in which display unevenness is easily caused by fluctuations in element thickness.

[0033] Examples of methods for forming a photosensitive resin layer on a support include: (a) by a known coating method, a method of applying a solution including the photosensitive composition of the present invention, and (b) laminating by a transfer printing method Photosensitive resin transfer film method. Each method will be described in detail below.

[0034] (a) Coating method

[0035] The photosensitive composition can be applied by known methods such as spin coating, curtain coating, slot coating, dip coating, air knife coating, roll coati...

Embodiment 1

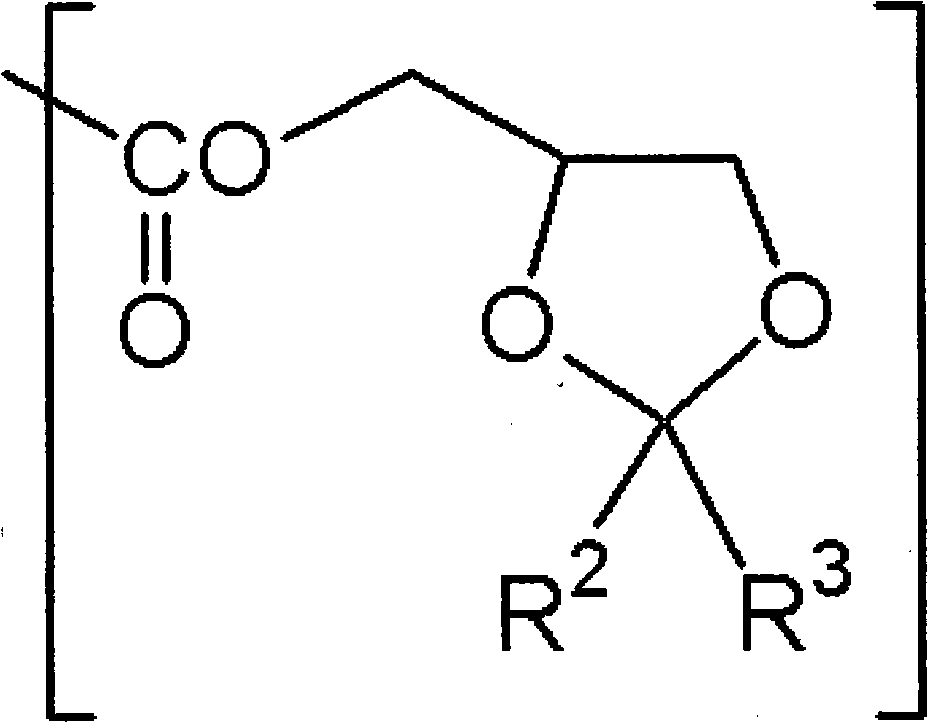

[0204] 2.45 parts of 1-methoxy-2-propanol (trade name: MFG, manufactured by Nippon Nyukazai Co., Ltd.) was placed in the reaction vessel, followed by heating to 90°C. Into a reaction vessel at 90° C., under a nitrogen atmosphere, 2.07 parts of MMDOL 30 (trade name, manufactured by Osaka Organic Chemical Industry Ltd.), 1.20 parts of methacrylic acid, 0.22 parts of dimethicone were added dropwise over 2 hours. Nitrogen polymerization initiator (trade name: V-601, manufactured by Wako Pure Chemical Industries, Ltd.) and a mixed solution consisting of 2.07 parts and 1-methoxy-2-propanol. After the addition, the components were reacted, whereby an acrylic resin solution was obtained.

[0205] Next, to the acrylic resin solution, 0.0068 parts of hydroquinone monomethyl ether and 0.02 parts of tetraethylammonium bromide were added, and then 1.23 parts of glycidyl methacrylate was added dropwise to the join in it. After being added by dropwise addition, the components were reacted ...

Embodiment 2

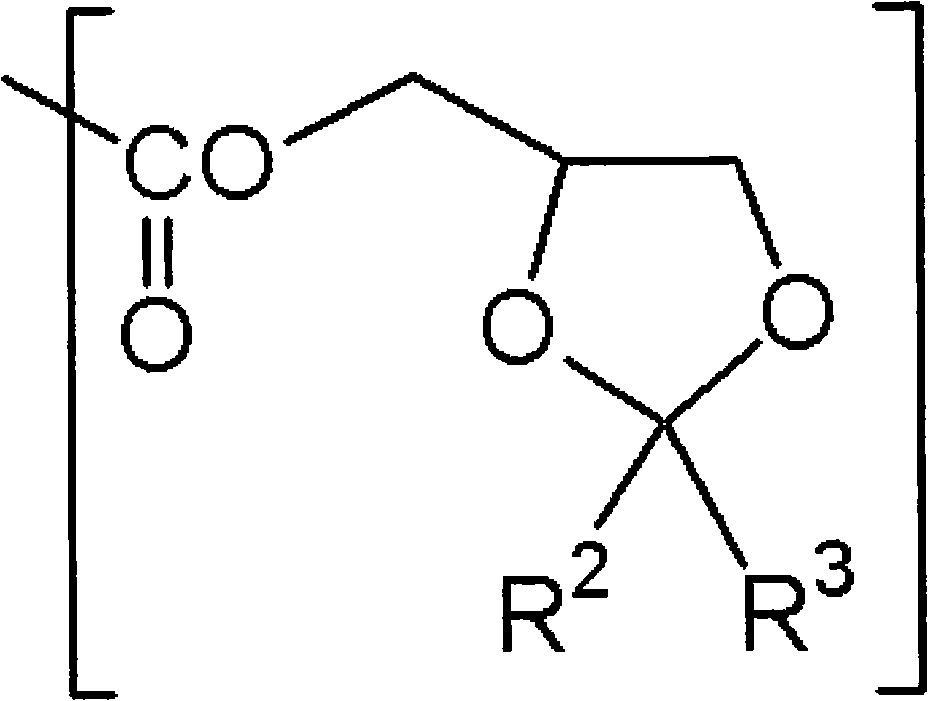

[0210] In Synthesis Example 2, the synthesis of the resin (A) represented by the compound structure P-2 will be described.

[0211] In the same manner as in Synthesis Example 1, a solution of the resin represented by the compound structure P-2 having an unsaturated group (45% solution in 1-methoxy-2-propanol, solid content acid value: 52.1mg KOH / g, Mw: 15,000), the difference is: MEDOL 30 (trade name, manufactured by Osaka Organic Chemical Industry Ltd.), methacrylic acid and glycidyl methacrylate were added to The ratio x:y:z in compound structure P-2 was set to 47.5 mol%:18.2 mol%:34.3 mol% instead of adding MMDOL 30, methacrylic acid and glycidyl methacrylate in Synthesis Example 1.

[0212] The obtained resin (A) specifically has a structure represented by compound structure P-2, wherein R X is methyl, R Y is methyl, and R Z For methyl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com