Synthetic method of decahedron nanogold

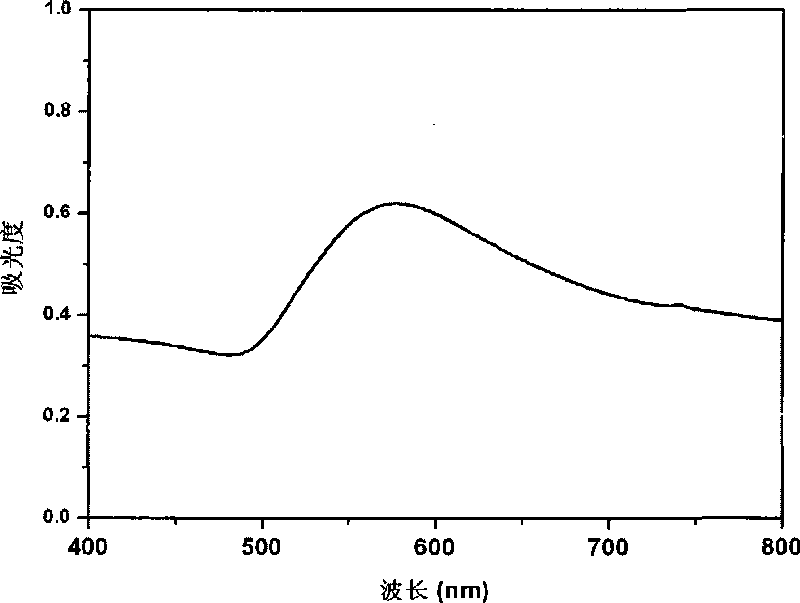

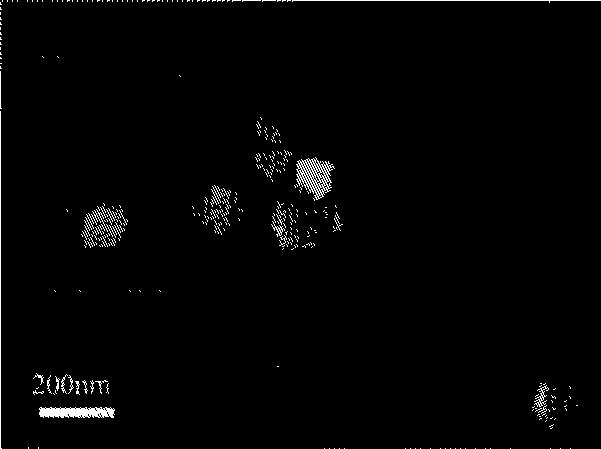

A synthesis method and nano-gold technology, applied in the field of nano-gold, can solve the problems of low yield, non-uniform particle size of decahedral nano-gold particles, complex synthesis steps, etc., and achieve easy separation, simple operation, and particle size. Narrow distribution of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Take 0.277g polyvinylpyrrolidone, dissolve it in 20mL N, N'-dimethylamide, stir evenly, the molecular weight of polyvinylpyrrolidone is 8000.

[0027] 2) Add the chloroauric acid solution and stir at room temperature for 10 minutes to obtain a reaction precursor solution. The concentration of chloroauric acid is 0.01M in molar ratio, and the ratio of polyvinylpyrrolidone: chloroauric acid is 100:1.

[0028] 3) Pour the reaction precursor solution into a microwave reaction tank, and put it into a microwave reactor, the reaction temperature is 150° C., and the reaction time is 30 minutes.

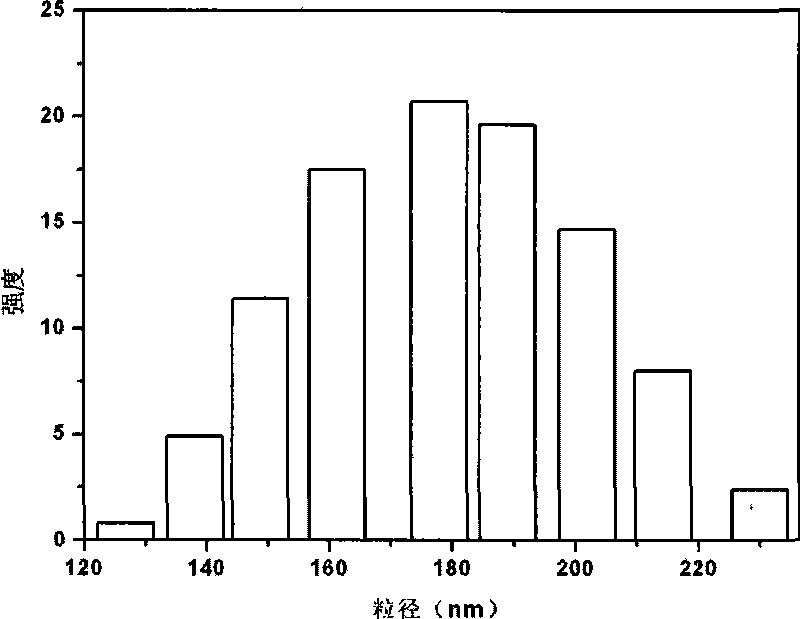

[0029] 4) The reaction system was naturally cooled to room temperature. Centrifuge at a rotational speed of 3000 rpm to separate the synthesized gold nanoparticles from polyvinylpyrrolidone, and then wash with absolute ethanol for 3 times. The particle size of the obtained decahedral gold nanoparticles is about 180nm.

Embodiment 2

[0031] 1) Take 0.277g polyvinylpyrrolidone, dissolve it in 23mL N, N'-dimethylamide, stir well, the molecular weight of polyvinylpyrrolidone is 20000.

[0032] 2) Add chloroauric acid solution and stir at room temperature for 10 minutes to obtain a reaction precursor solution. The concentration of chloroauric acid is 0.001M in molar ratio, and the ratio of polyvinylpyrrolidone: chloroauric acid is 50:1.

[0033] 3) Pour the reaction precursor solution into a microwave reaction tank, and put it into a microwave reactor, the reaction temperature is 200° C., and the reaction time is 1 min.

[0034] 4) The reaction system was naturally cooled to room temperature. Centrifuge at a rotational speed of 2500 rpm to separate the synthesized gold nanoparticles from polyvinylpyrrolidone, and then wash with deionized water for 3 times. The particle size of the obtained decahedral gold nanoparticles is about 180nm.

Embodiment 3

[0036] 1) Take 0.277g polyvinylpyrrolidone, dissolve it in 24.5mL N, N'-dimethylamide, stir evenly, the molecular weight of polyvinylpyrrolidone is 63000.

[0037] 2) Add the chloroauric acid solution and stir at room temperature for 10 minutes to obtain a reaction precursor solution. The concentration of chloroauric acid is 0.05M in molar ratio, and the ratio of polyvinylpyrrolidone: chloroauric acid is 500:1.

[0038] 3) Pour the reaction precursor solution into a microwave reaction tank, and put it into a microwave reactor, the reaction temperature is 100° C., and the reaction time is 60 minutes.

[0039] 4) The reaction system was naturally cooled to room temperature. Centrifuge at a rotational speed of 3500 rpm to separate the synthesized gold nanoparticles from polyvinylpyrrolidone, and then wash with acetone for 3 times. The particle size of the obtained decahedral gold nanoparticles is about 100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com