Polysilicon preparation method of recovering hydrogen chloride in circulating exhaust

A production method, hydrogen chloride technology, applied in the direction of silicon halide compounds, silicon, halosilane, etc., can solve the problems of underutilization, serious environmental pollution, waste of energy, etc., to reduce the generation and quantity of pollutants, The effect of solving environmental pollution problems and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

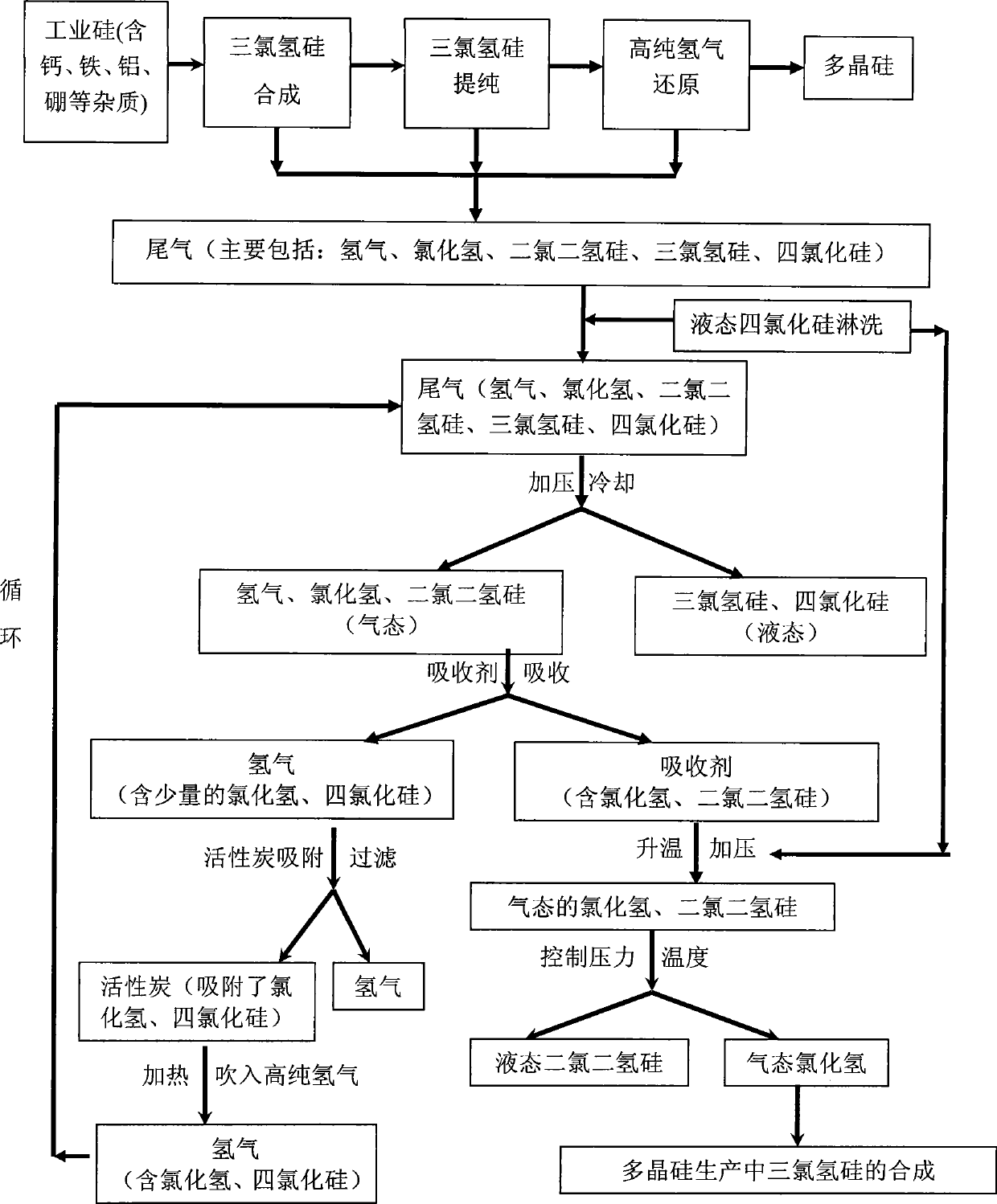

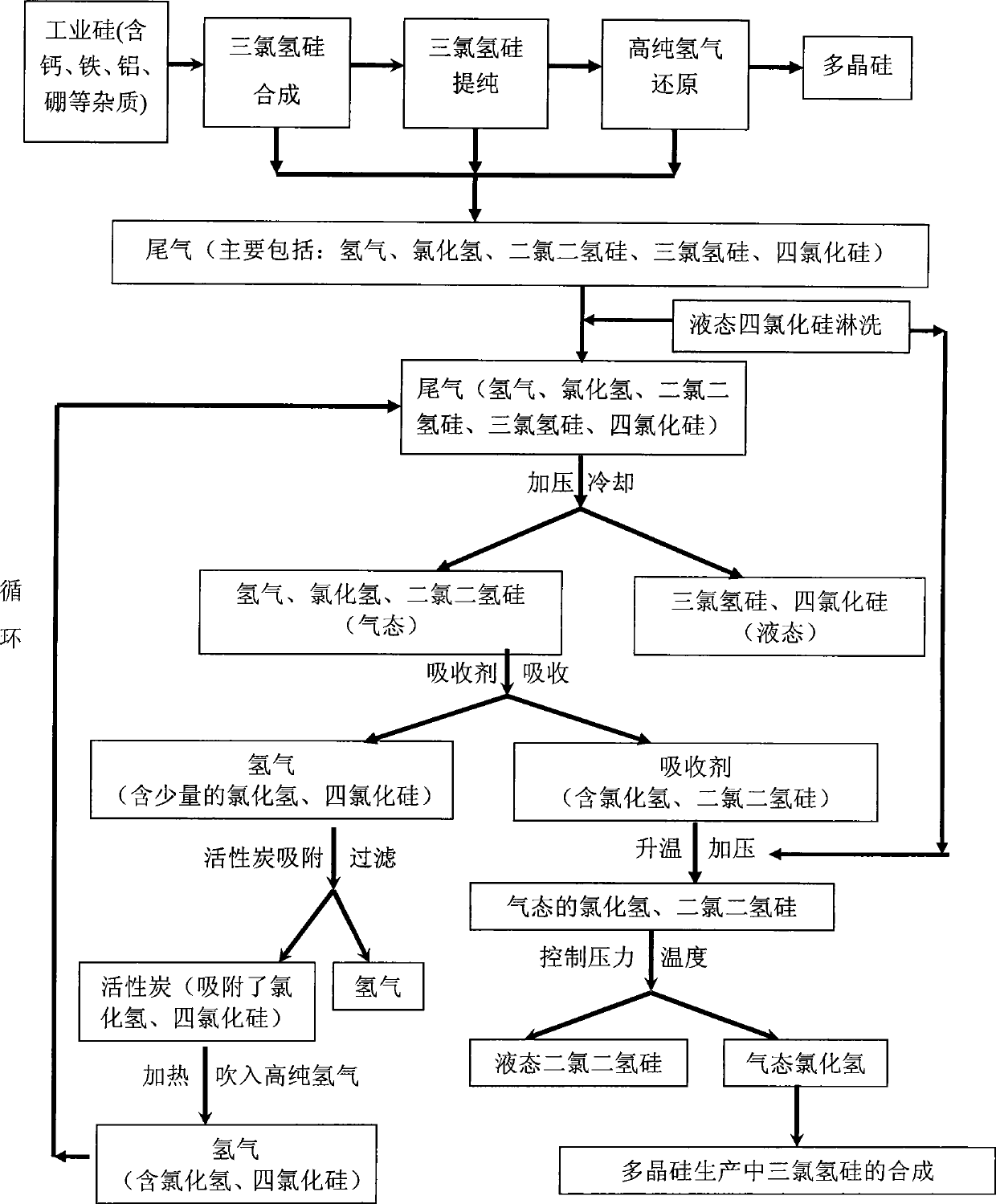

[0016] refer to figure 1 , which shows a flow chart of an improved polysilicon production method that can be applied according to an embodiment of the present invention. The polysilicon production process of the present invention uses industrial silicon and hydrogen chloride (HCl) as the main raw materials, and generates the following by controlling the reaction conditions. Trichlorosilane (SiHCl 3 )-based mixture of chlorosilane and hydrogen, and then trichlorosilane (SiHCl 3 ) after being purified, sent to the reduction furnace to make trichlorosilane (SiHCl 3 ) and auxiliary material hydrogen (H 2 ) reaction, reduction to generate polysilicon.

[0017] In the process of the above-mentioned industrial production of polysilicon, the tail gas produced mainly includes hydrogen (H 2 ), hydrogen chloride (HCl), and chlorosilanes, which mainly include dichlorodihydrosilane (SiH 2 Cl 2 ), trichlorosilane (SiHCl 3 ) and silicon tetrachloride (SiCl 4 ).

[0018] The main rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com