Method for recovering tail gas generated by polycrystalline silicon production

A technology of polysilicon and exhaust gas, applied in the direction of halosilane, metal silicide, silicon halide compound, etc., can solve the problems of insufficient utilization of hydrogen, environmental pollution, large material consumption, and increased cost, and reduce pollutants The production and quantity, the effect of saving project investment and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments are described below in order to explain the present invention by referring to the figures, and the described embodiments are exemplary and should not be construed as limitations of the present invention.

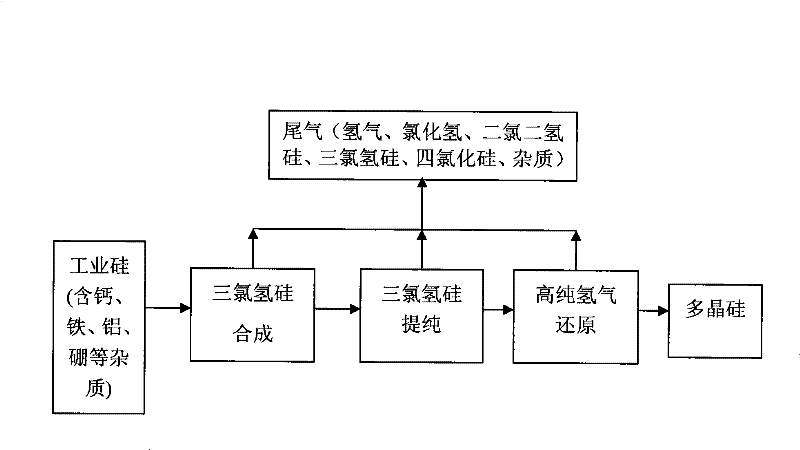

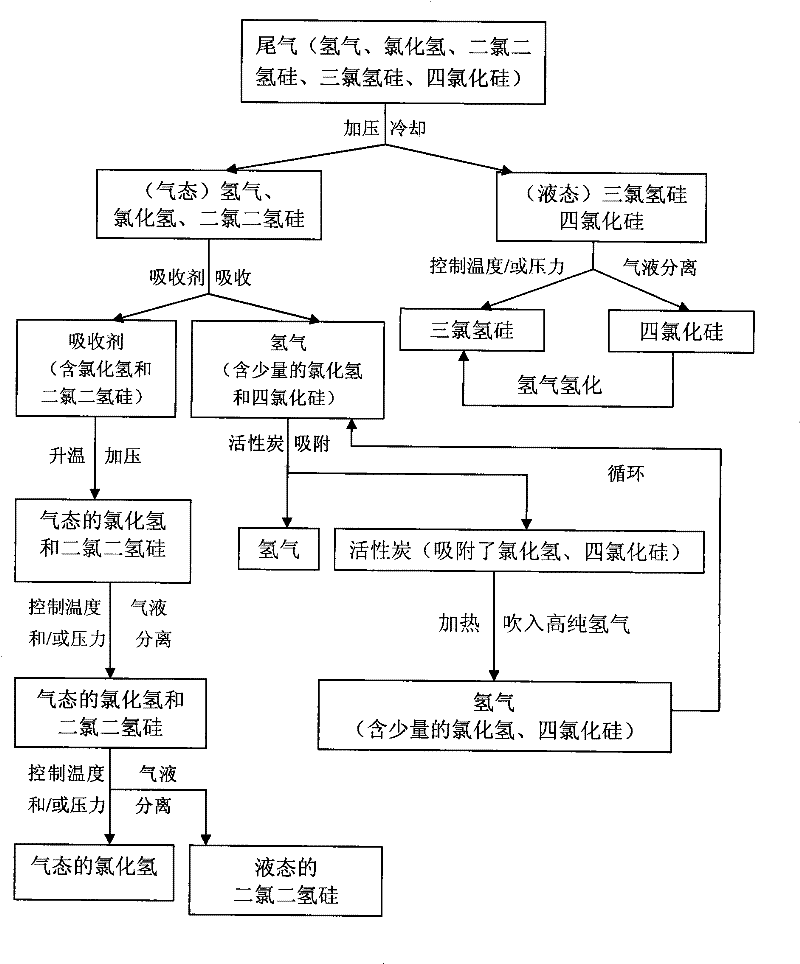

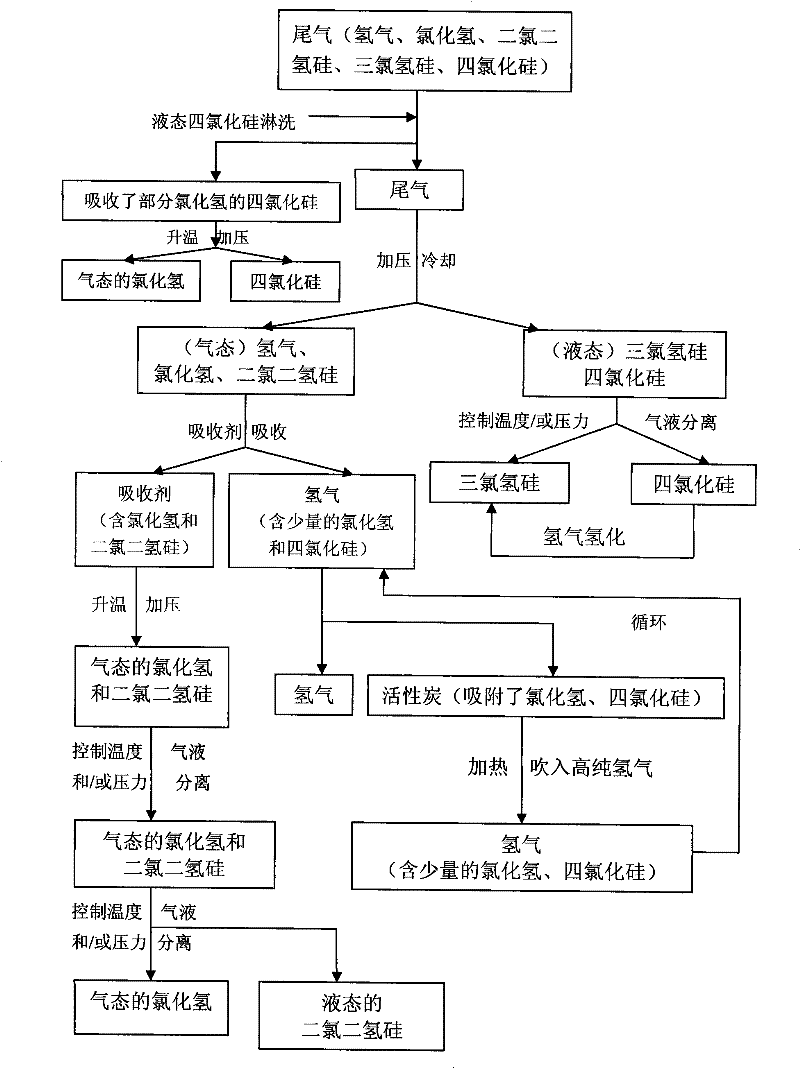

[0027] refer to figure 1 , which shows a flow chart of the industrial production of polysilicon that can be applied to the method for recovering the tail gas produced by the production of polysilicon according to an embodiment of the present invention. In the prior art, there are multiple methods that can be used to produce industrialized polysilicon. Apply the present invention The advanced polysilicon production process uses industrial silicon and hydrogen chloride (HCl) as the main raw materials, and generates trichlorosilane (SiHCl) by controlling the reaction conditions. 3 )-based mixture of chlorosilane and hydrogen, and then through the purification technology of trichlorosilane (SiHCl 3 ) after being purified, sent to the reduction furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com