Feeding method for smelting silicium magnesium laterite ore

A feeding method and technology of laterite ore, which is applied in the feeding field of smelting silicon-magnesium laterite ore, can solve the problems of low recovery rate, high nickel content, complicated process, etc., and achieve the effect of sufficient matte-making reaction and enhanced air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

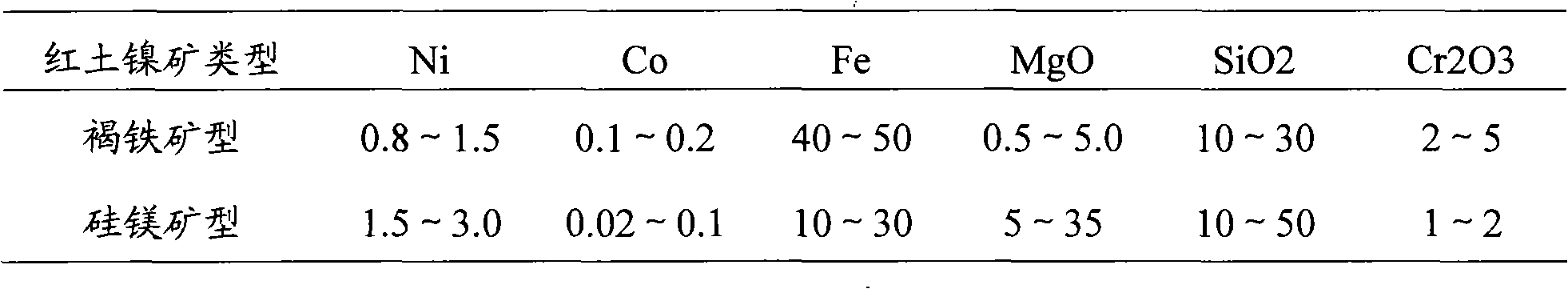

[0049] Laterite ore R in the present embodiment 1 Its water content is 33.5%, see Table 2 for other ingredients except water.

[0050] Get the laterite ore R of 150 weight parts 1 After being sieved through a sieve with an aperture of 40mm, the first mass part M1 with a block diameter of less than 40mm and the second mass part M2 with a block diameter greater than 40mm are obtained respectively, and the second mass part M2 is broken into fragments with a particle size less than 80mm; 18.3 parts by weight of gypsum powder were mixed with the first mass part M1 and placed in the brick making machine to make adobe. The strength and density of the adobe measured are listed in Table 3.

[0051] Take 4.1 parts by weight of limestone as flux.

[0052] The charge composition is 150 parts by weight of laterite ore, 18.3 parts by weight of gypsum powder, and 4.0 parts by weight of limestone.

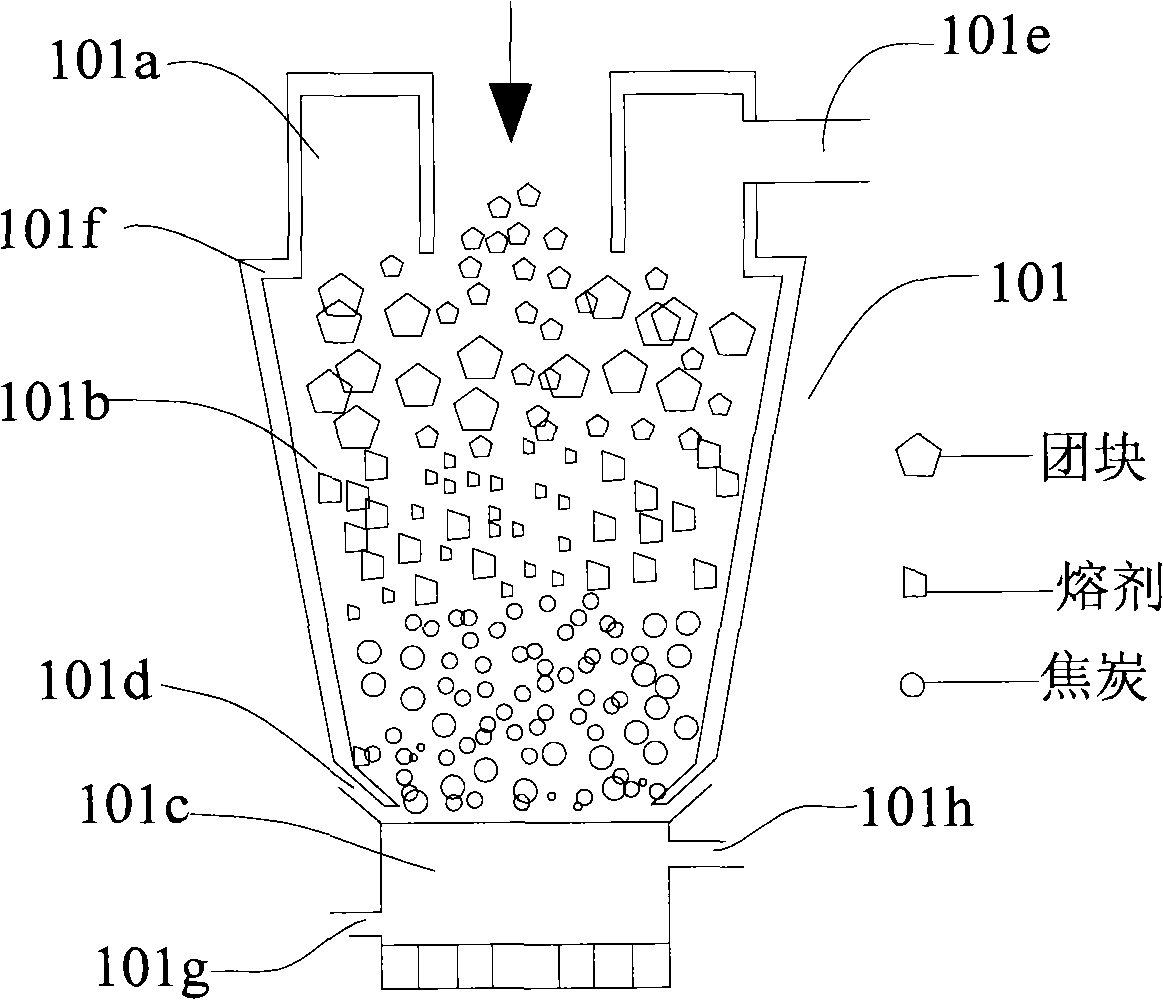

[0053] During smelting, the furnace charge is sent into the blast furnace at a rate of 0.8t...

Embodiment 2

[0058] Laterite ore R in the present embodiment 2 Its water content is 31%, see Table 2 for other ingredients except water.

[0059] Get the laterite ore R of 145 weight parts 2 After being sieved through a sieve with an aperture of 50 mm, the first mass part M1 with a block diameter of less than 40 mm and the second mass part M2 with a block diameter greater than 40 mm were obtained, and the second mass part M2 was broken into fragments with a particle size less than 80 mm; 16.7 parts by weight of gypsum powder were mixed with the first mass part M1 and placed in the brick making machine to make adobe. The strength and density of the adobe measured are listed in Table 3.

[0060] Take 0.7 parts by weight of limestone as a flux.

[0061] The charge composition is 145 parts by weight of laterite, 16.7 parts by weight of gypsum powder, and 0.3 parts by weight of limestone.

[0062]During smelting, the furnace charge is sent into the blast furnace at a rate of 0.8tph (ton / hour...

Embodiment 3

[0067] Laterite ore R in the present embodiment 3 Its water content is 35.5%, see Table 2 for other ingredients except water.

[0068] Get the laterite ore R of 155 weight parts 3 After being sieved through a sieve with an aperture of 40mm, the first mass part M1 with a block diameter of less than 40mm and the second mass part M2 with a block diameter greater than 40mm were obtained respectively, and the second mass part M2 was broken into fragments with a particle size less than 80mm; 20.3 parts by weight of gypsum powder were mixed with the first mass part M1 and placed in a brick making machine to make adobe. The strength and density of the adobe measured are listed in Table 3.

[0069] The charge is composed of 150 parts by weight of laterite ore and 20.3 parts by weight of gypsum powder.

[0070] During smelting, the furnace charge is sent into the blast furnace at a rate of 0.8tph (ton / hour), coke is sent into the blast furnace at 0.2tph for reaction, and the air volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com