Method for directly extracting vanadium from vanadium titan magnetite concentrate

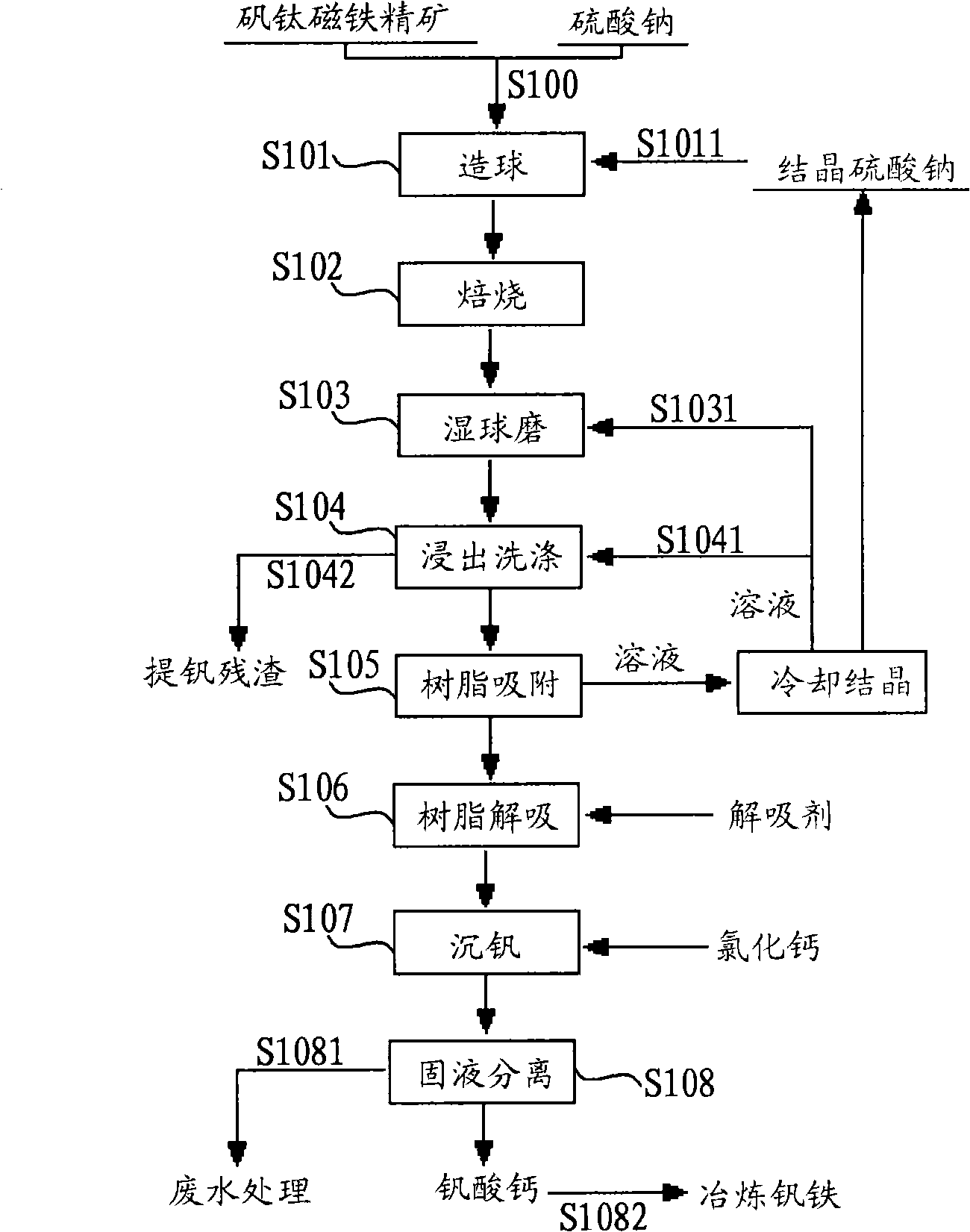

A vanadium-titanium-magnetite concentrate and direct technology are applied in the field of directly extracting vanadium from vanadium-titanium-magnetite concentrate, and can solve the problems of increased energy consumption, long leaching process time and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Get 2kg of Panzhihua vanadium-titanium magnetite concentrate (particle size: -200 mesh 67%; main component: V 2 o 5 0.769%, TFe 58.66%, FeO 27.08%, SiO2 1.52%, TiO 2 11.09%, MgO 1.63%, MnO 0.432%, Al 2 o 3 3.43%), add 0.12kg of anhydrous sodium sulfate into it, mix well and make pellets, the size of the pellets is 8-10mm, the pellets are heated to 1250°C in the muffle furnace and then kept for 60min; the roasted pellets are ground After the powdered material is leached with hot water, 4L of leaching solution with TV=1.895g / l is obtained, wherein, TV represents the total vanadium content, i.e. the content of metal vanadium; the leaching solution is adsorbed by 717 resin and desorbed by sodium hydroxide to obtain TV=24.3g 300ml of desorption liquid per 1; add 16g calcium chloride precipitation calcium vanadate to desorption liquid, obtain the calcium vanadate of 23.4gTV=30.8%.

Embodiment 2

[0040] Get 2.5kg of Panzhihua vanadium-titanium magnetite concentrate (particle size: -200 mesh 67%; main component: V 2 o 5 0.769%, TFe 58.66%, FeO 27.08%, SiO 2 1.52%, TiO 2 11.09%, MgO 1.63%, MnO 0.432%, Al 2 o 3 3.43%), add 0.15kg of anhydrous sodium sulfate therein, mix and pelletize, the size of the pellets is 8-12mm; the pellets are heated to 1250°C in the muffle furnace and then kept for 60min; the roasted pellets are ground into After the powder is leached with hot water, 4.58L of leaching solution with TV=2.07g / l is obtained; the leaching solution is adsorbed with 717 resin and desorbed with sodium hydroxide to obtain 361ml of desorption solution with TV=25.2g / l; add 20g of chloride Calcium precipitated calcium vanadate, yielding 29.7 g TV=30.2% calcium vanadate.

Embodiment 3

[0042] Get 1.7kg of Panzhihua Baima vanadium-titanium magnetite concentrate (particle size: -200 mesh 67%; main component: V 2 o 5 0.769%, TFe 58.66%, FeO 27.08%, SiO 2 1.52%, TiO 2 11.09%, MgO 1.63%, MnO 0.432%, Al 2 o 3 3.43%), add 0.10kg of anhydrous sodium sulfate therein, mix and make pellets, the size of the pellets is 8-12mm; the pellets are heated to 1250°C in the muffle furnace and then kept for 60min; the roasted pellets are ground into After the powder is leached with hot water, 3.46L of leaching solution with TV=1.86g / l is obtained; the leaching solution is extracted with N-263, back-extracted with sodium hydroxide and sodium chloride, and 361ml of back-extraction solution with TV=23.6g / l is obtained; Add 20 g of calcium chloride to precipitate calcium vanadate into the desorption solution to obtain 20.8 g of calcium vanadate with a TV=29.4%.

[0043] It can be seen from the above three examples that examples 1 and 2 use ion exchange resins to purify the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com