Paperboard containing microplatelet cellulose particles

A technology of crystalline cellulose and cardboard, which is applied in the field of cardboard containing microlamellar cellulose particles, which can solve the problems of damage to bending stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following detailed description illustrates specific embodiments of the invention; however, it is not intended to limit the scope of the appended claims in any way.

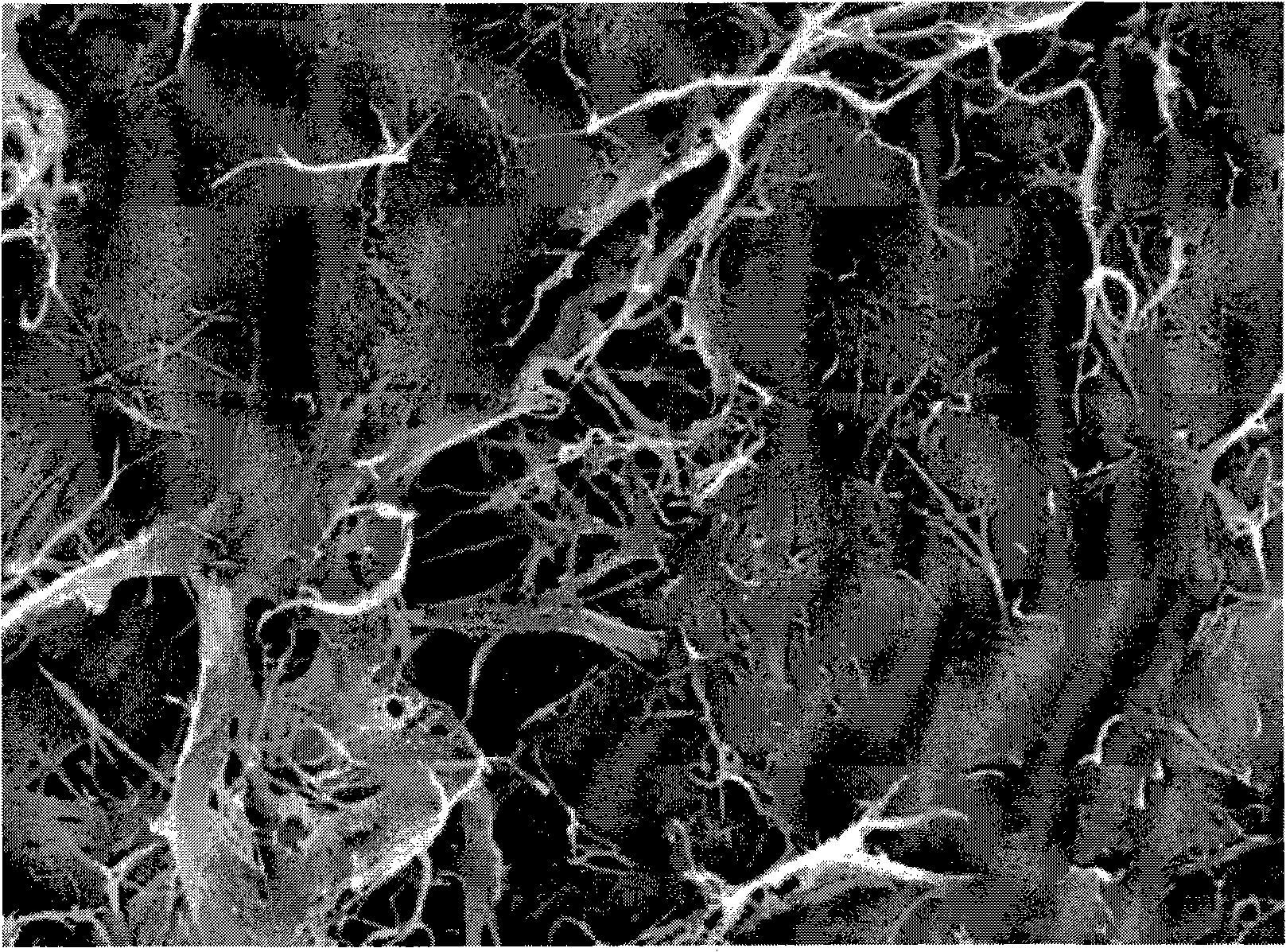

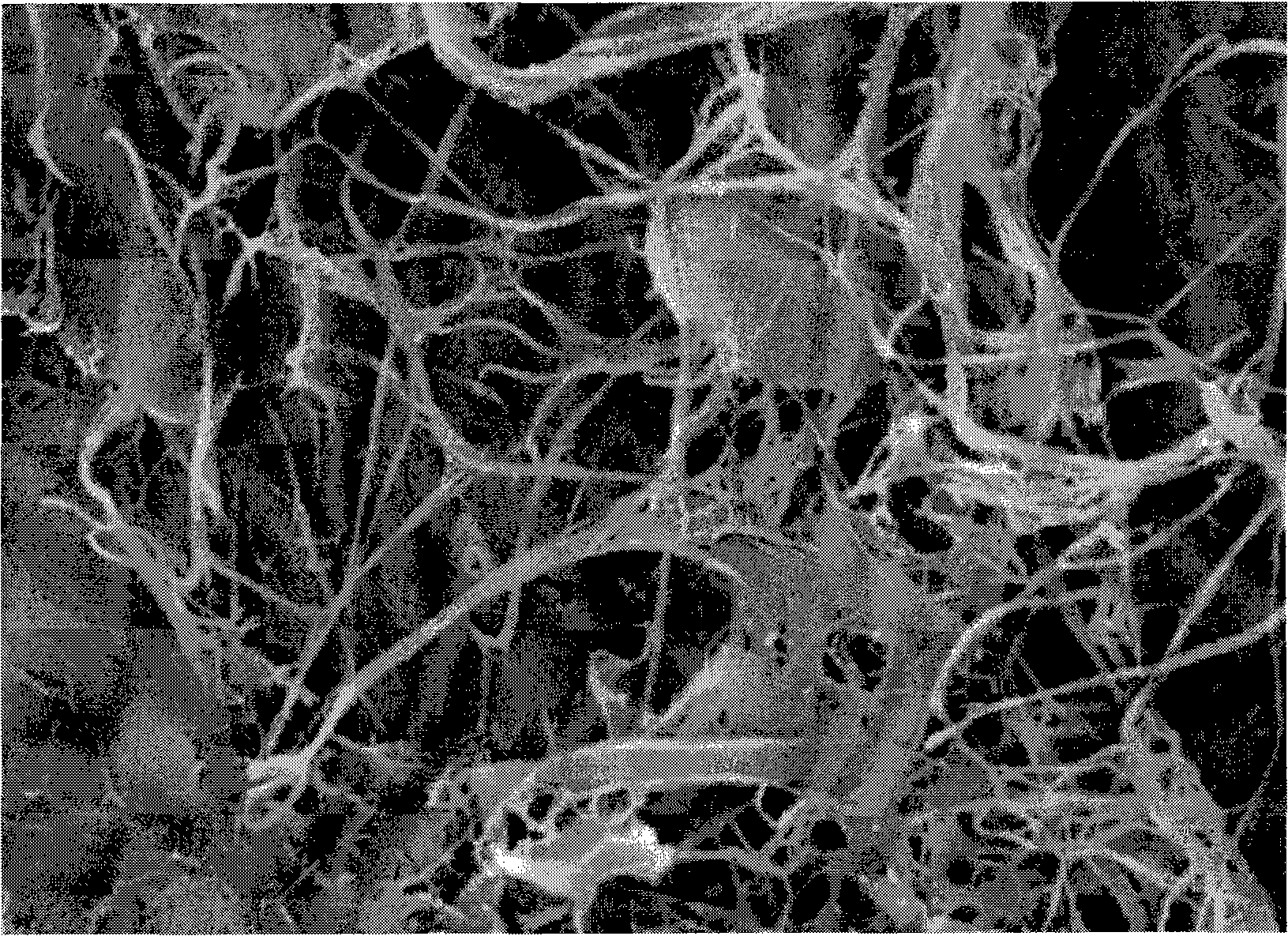

[0027] The microlamellar cellulose MPC particles of the present invention can be obtained by passing a suspension of fiber pulp through a high friction mill or a whetstone mill at atmospheric pressure at a temperature ranging from about 20°C to about 95°C. The fiber pulp was repeatedly ground through several times, and the volume average particle size of MPC in the obtained aqueous suspension was measured by Microtrac X-100Tri-Laser-System, a laser scattering particle size analyzer, after each pass. figure 1 and 2 It is the SEM picture of the dry state of the disclosed MPC.

[0028] The MPC of the present invention has a volume average particle size ranging from about 20 microns to about 150 microns, a number average particle size ranging from about 5 microns to about 20 microns, and a volume average p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com