Nano leadless soldering paste

A technology of lead-free solder paste and lead-free solder, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of lead poisoning and achieve the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The nano-lead-free solder paste of the present embodiment is made up of Sn-Ag-Cu nano-lead-free solder powder and rosin no-cleaning flux, with a total weight of 10g, and its composition is calculated by mass fraction as:

[0017] Nano lead-free solder powder 90 parts

[0018] Flux 10 parts

[0019] The mass percent of each element in the nanometer lead-free solder powder is:

[0020] Ag 4.0%;

[0021] Cu 0.5%;

[0022] Sn margin.

[0023] a. The nanopowder stored in the paraffin liquid is separated, and chloroform is selected as the separation solvent.

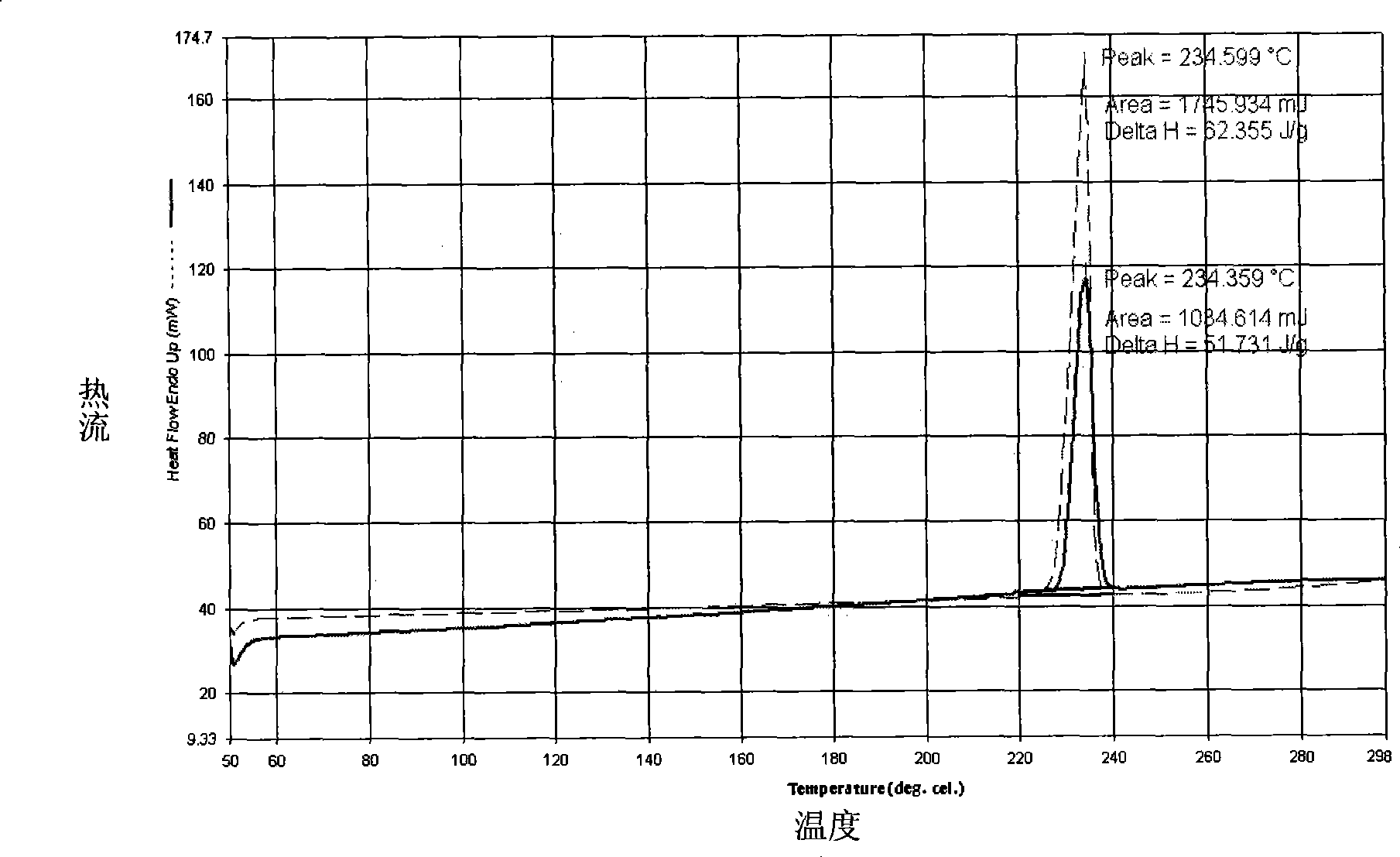

[0024] b. Mix the separated nano-powder and rosin no-cleaning flux evenly to make solder paste, and its melting point is lowered as shown in figure 1 .

Embodiment 2

[0026] The nano-lead-free solder paste of the present embodiment is made up of Sn-Co-Cu nano-lead-free solder powder and rosin no-clean flux, with a total weight of 10g, and its composition is calculated by weight fraction:

[0027] Nano lead-free solder powder 90 parts

[0028] Flux 10 parts

[0029] The mass percent of each element in the nanometer lead-free solder powder is:

[0030] Cu 0.7%;

[0031] Co 0.4%

[0032] Sn margin.

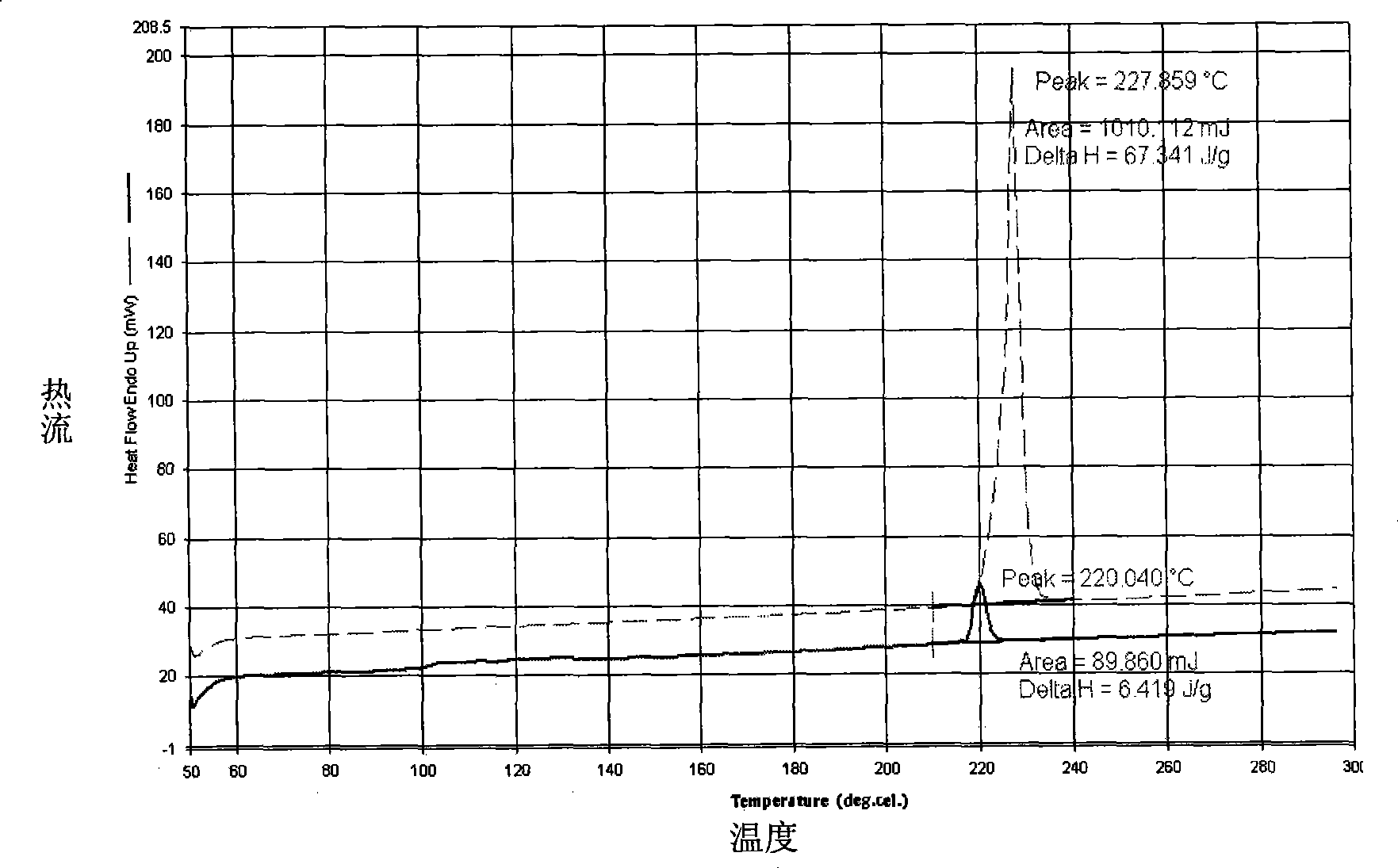

[0033] The nanometer powder stored in the paraffin liquid is separated, and chloroform is selected as the separation solvent. Mix the separated nano-powder with rosin no-cleaning flux evenly to make a solder paste, and its melting point is lowered as shown in figure 2 . Example 3

Embodiment 3

[0034] The nano-lead-free solder paste of the present embodiment is made up of Sn-Bi nano-lead-free solder powder and rosin no-clean flux, with a total weight of 10g, and its composition is calculated by weight fraction:

[0035] Nano lead-free solder powder 90 parts

[0036] Flux 10 parts

[0037] The mass percent of each element in the nanometer lead-free solder powder is:

[0038] Bi 57%

[0039] Sn margin.

[0040] The nanometer powder stored in the paraffin liquid is separated, and chloroform is selected as the separation solvent. The separated nano-powder is evenly mixed with rosin no-cleaning flux to prepare a solder paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com