Method for preparing transparent hydrophobic coating

A super-hydrophobic coating and transparent technology, which is applied in the field of preparation of hydrophobic coatings, can solve the problems of poor applicability and high production cost of transparent super-hydrophobic surfaces, and achieve the effects of low cost, easy availability of raw materials, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Preparation of coating sol:

[0046]Dissolve 2.04g of aluminum isopropoxide in 20.4g of toluene, add 1.3g of ethyl acetoacetate after complete dissolution, fully stir for reaction, add 0.72g of deionized water, stir for reaction, and obtain a coating sol;

[0047] (2) Coating film on the surface of the base material:

[0048] Immerse the glass sheet in the sol prepared in step (1), slowly and uniformly extract it from the sol with a pulling machine, the pulling speed is 2mm / s, and leave it at room temperature for use after being proposed;

[0049] (3) Hydrophobic self-assembly surface modification process:

[0050] Immerse the glass sheet coated in step (2) in 10mM n-hexane solution of stearic acid, carry out self-assembly reaction for 24 hours, then rinse repeatedly with n-hexane, and dry it in an oven at 100°C to obtain a transparent superhydrophobic coating. Floor.

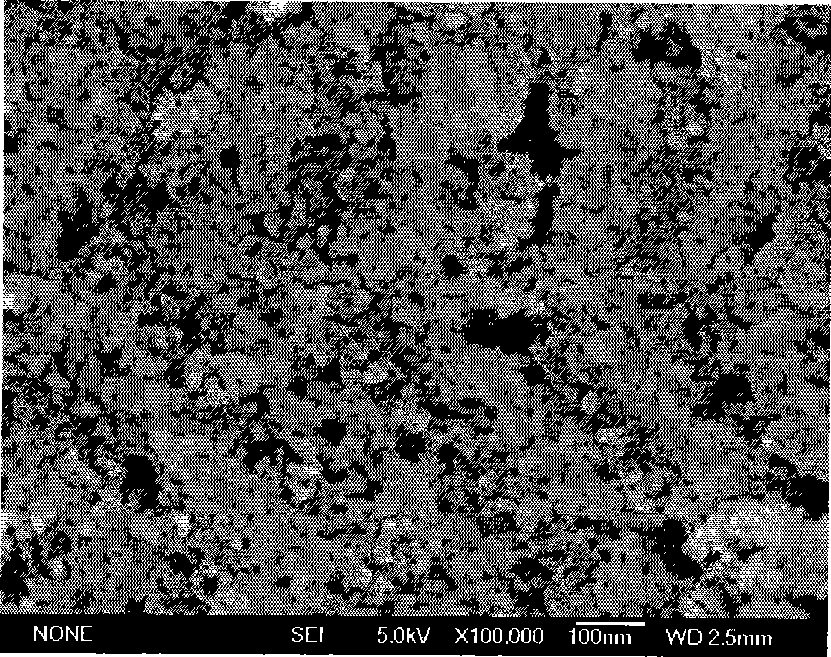

[0051] as attached figure 1 The field emission scanning electron microscope photo of the coat...

Embodiment 2

[0053] (1) Preparation of coating sol:

[0054] Dissolve 1.53g of aluminum isopropoxide in 20.4g of toluene, add 0.75g of acetylacetone after complete dissolution, fully stir for reaction, add 0.54g of deionized water, stir for reaction, and obtain a coating sol;

[0055] (2) Coating film on the surface of the base material:

[0056] Immerse the glass sheet in the sol prepared in step (1), slowly and uniformly extract it from the sol with a pulling machine, the pulling speed is 3mm / s, and leave it standing at room temperature for later use;

[0057] (3) Hydrophobic self-assembly surface modification process:

[0058] Immerse the glass sheet coated with film in step (2) in the n-hexane / carbon tetrachloride (70 / 30, V / V) solution of 4mM tetrahydroperfluorodecyl trichlorosilane, carry out self-assembly reaction 1h, then use Rinse with dichloromethane, and dry in an oven at 50°C to obtain a transparent super-hydrophobic coating.

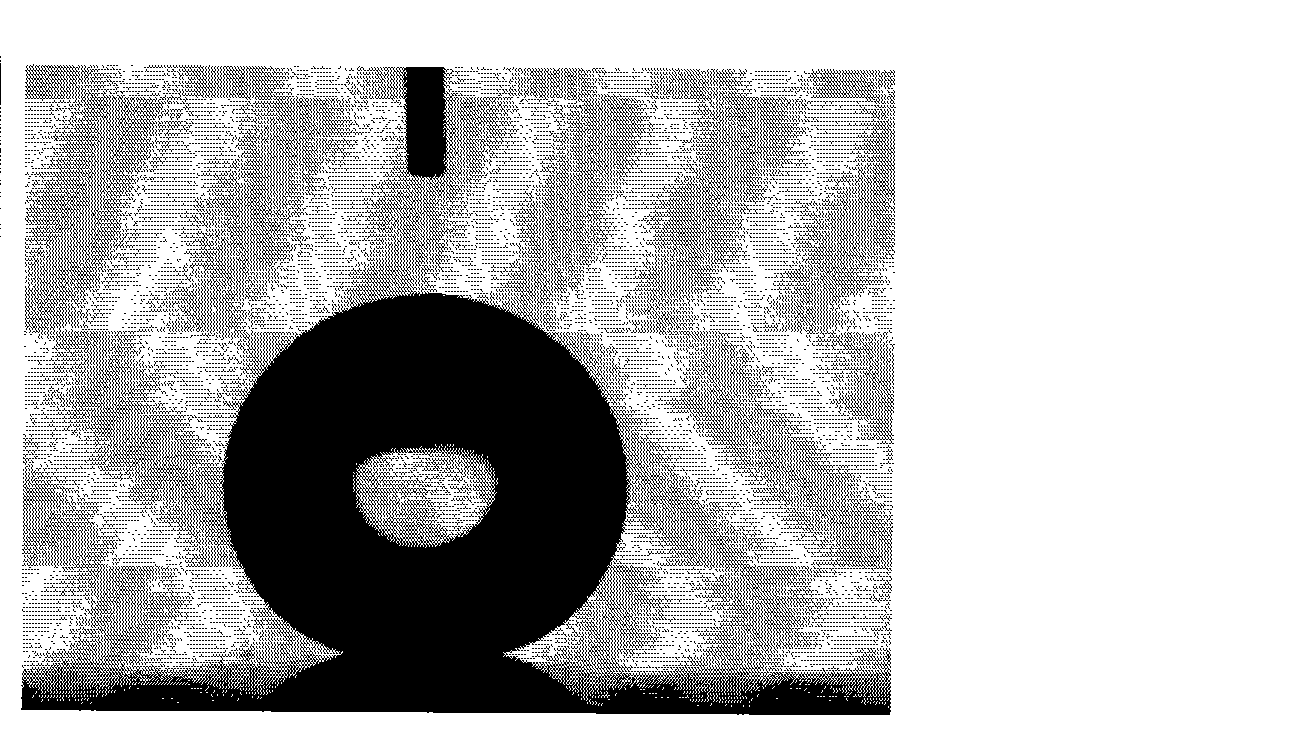

[0059] as attached image 3 As shown, the surfa...

Embodiment 3

[0061] (1) Preparation of coating sol:

[0062] Dissolve 1.02g of aluminum isopropoxide in 20.4g of toluene, add 0.66g of ethyl acetoacetate after complete dissolution, fully stir for reaction, add 0.36g of deionized water, stir for reaction, and obtain a coating sol;

[0063] (2) Coating film on the surface of the base material:

[0064] Immerse the glass piece in the sol prepared in step (1), and lift it out of the sol slowly and uniformly with a pulling machine at a pulling speed of 3 mm / s. After putting it out, let it stand at room temperature for 30 minutes, and repeat the previous operation for the second time. Coating, and then stand at room temperature for use;

[0065] (3) Hydrophobic self-assembly surface modification process:

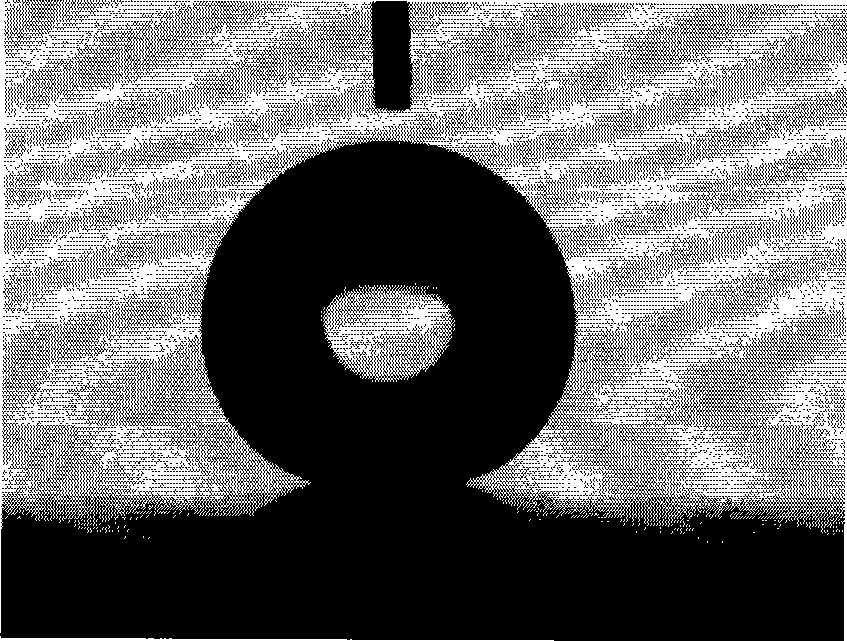

[0066] Immerse the glass sheet coated with film in step (2) in the n-hexane / carbon tetrachloride (70 / 30, V / V) solution of 4mM tetrahydroperfluorodecyl trichlorosilane, carry out self-assembly reaction 1h, then use Rinse with dichloromethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com