Combined double preheating device

A preheating device, combined technology, applied in blast furnace parts, furnaces, heating furnaces, etc., can solve the problems of high price and tension, and achieve the best effect of increasing temperature, increasing physical heat, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

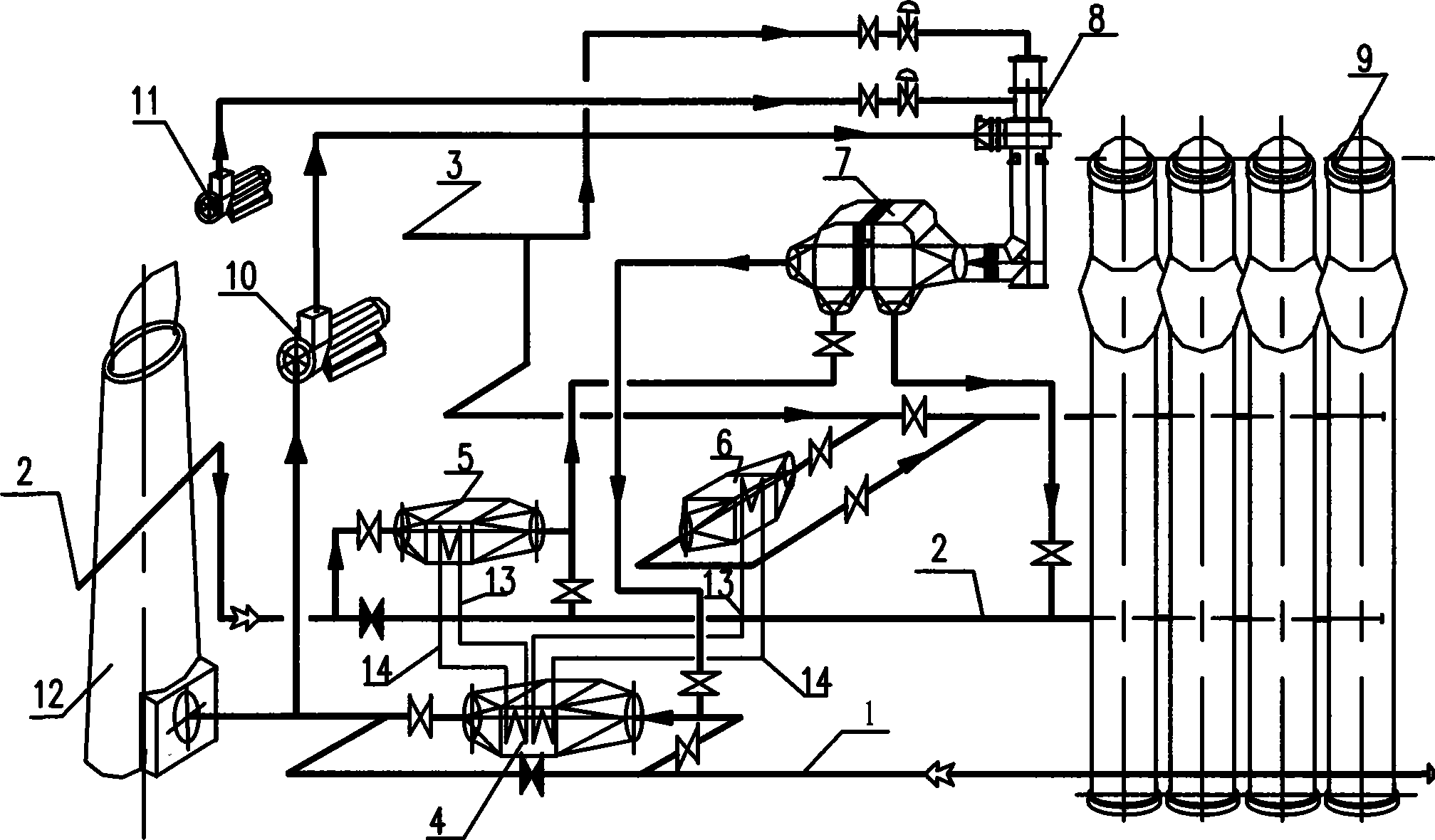

[0013] Embodiment 1: as figure 1 As shown, the first-stage preheater of the combined preheater is a separate heat pipe heat exchanger; the second stage is a shell-and-tube heat exchanger and is equipped with a new flue gas generator. The separated heat pipe heat exchanger is composed of three heat exchangers 4, 5, 6 for flue gas 1, air 2 and coal gas 3 and connecting pipes (rising pipe 13 and descending pipe 14). The first stage of preheating is to use the sensible heat of flue gas from the hot blast stove to heat the medium in the heat pipe in the flue gas heat pipe heat exchanger 4, so that it is vaporized into steam and enters the air heat pipe heat exchanger 5 and the gas heat pipe respectively along the riser pipe 13. Heat exchanger 6 heats the air to about 180°C and the gas to about 200°C. After the medium in the heat pipe gives heat to the air and gas, it is cooled to water and then flows back to the flue gas heat pipe heat exchanger 4 along the downcomer 14 to be heat...

Embodiment 2

[0019] Example 2: As shown in Figure 2, the primary preheating device of the combined preheating device is an integral heat pipe heat exchanger; the second stage is a shell and tube heat exchanger, and is equipped with a new type of flue gas generator . The integral heat pipe heat exchanger is composed of a number of single heat pipes, a box and a partition, etc. (the difference between embodiment 2 and embodiment 1 lies in the first-stage preheating device). The heating end of a single heat pipe is placed in the flue gas heat exchange side box of the integral heat pipe heat exchanger; the cooling end is placed in the air heat exchange side box or the gas heat exchange side box. With the heat transfer function of each heat pipe, part of the heat of the flue gas is transferred to the air and gas. Make the air temperature reach about 180°C; make the gas temperature reach about 200°C.

[0020] The preheating process flow of the second stage is the same as that of Embodiment 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com