Cooling channel piston of an internal combustion engine and method for manufacturing the same

A technology for cooling channels and internal combustion engines, which is applied to pistons, manufacturing tools, cylindrical pistons, etc., can solve the problem of insufficient cooling of the piston, and achieve high requirements, reduce the weight of the piston, and have a solid structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

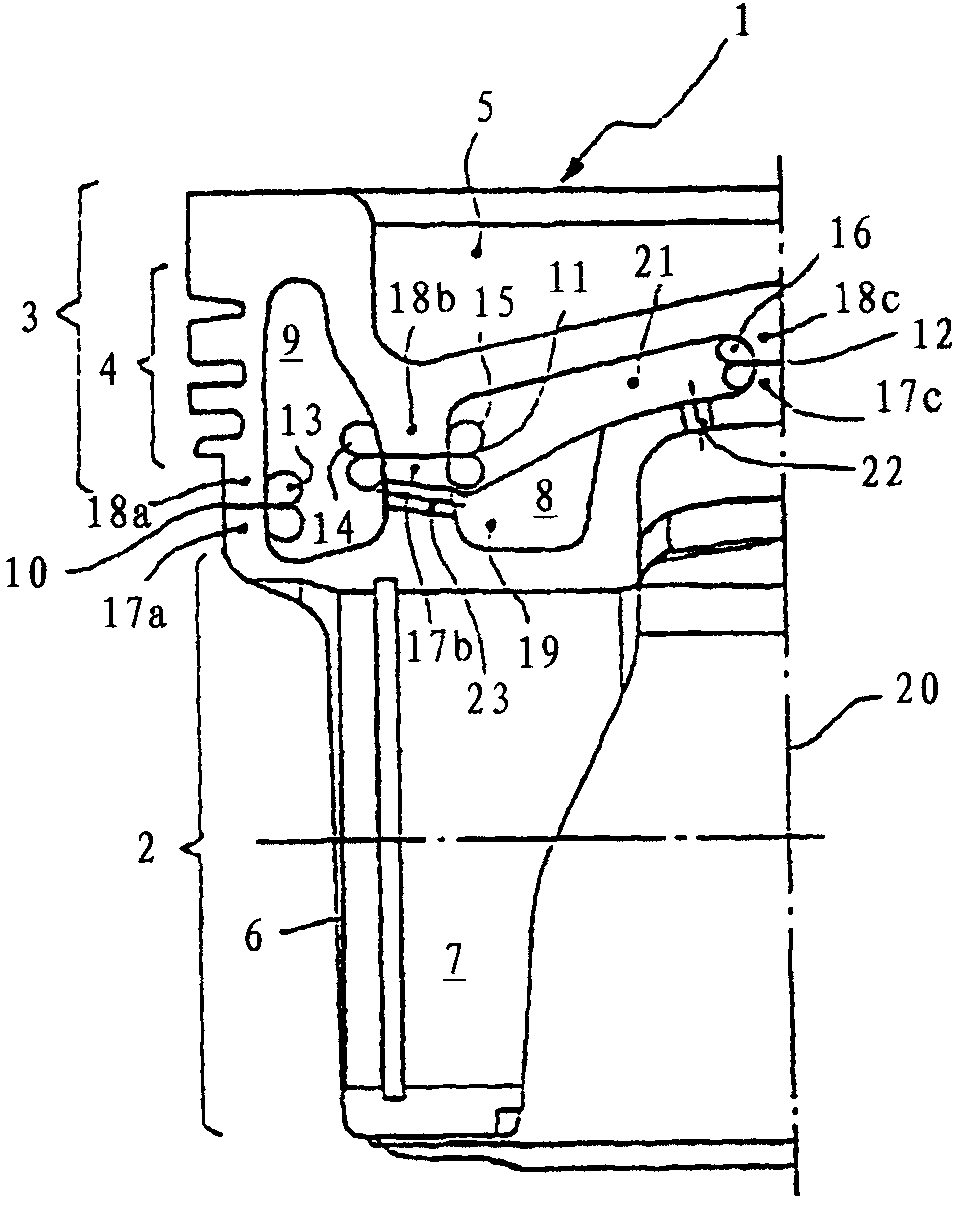

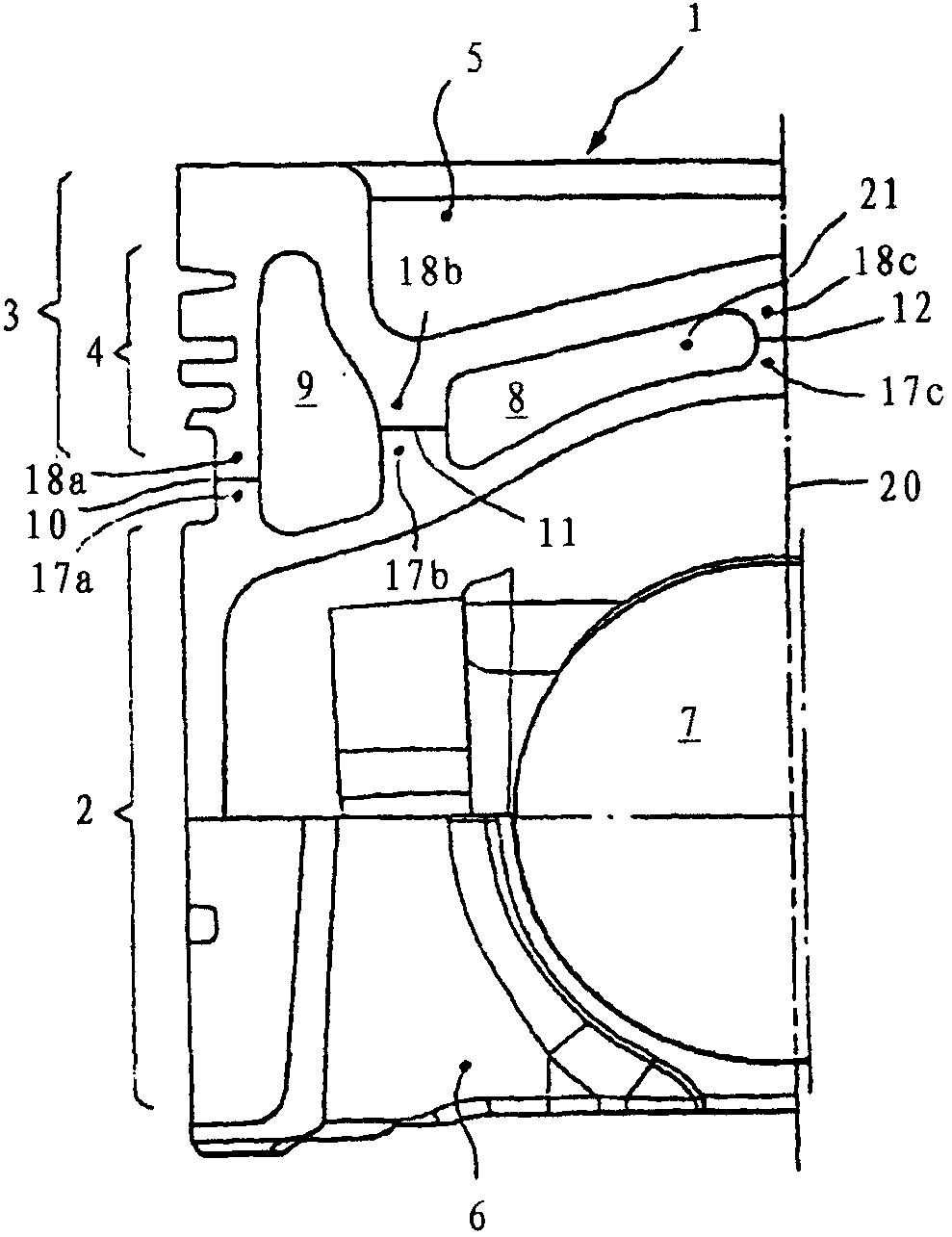

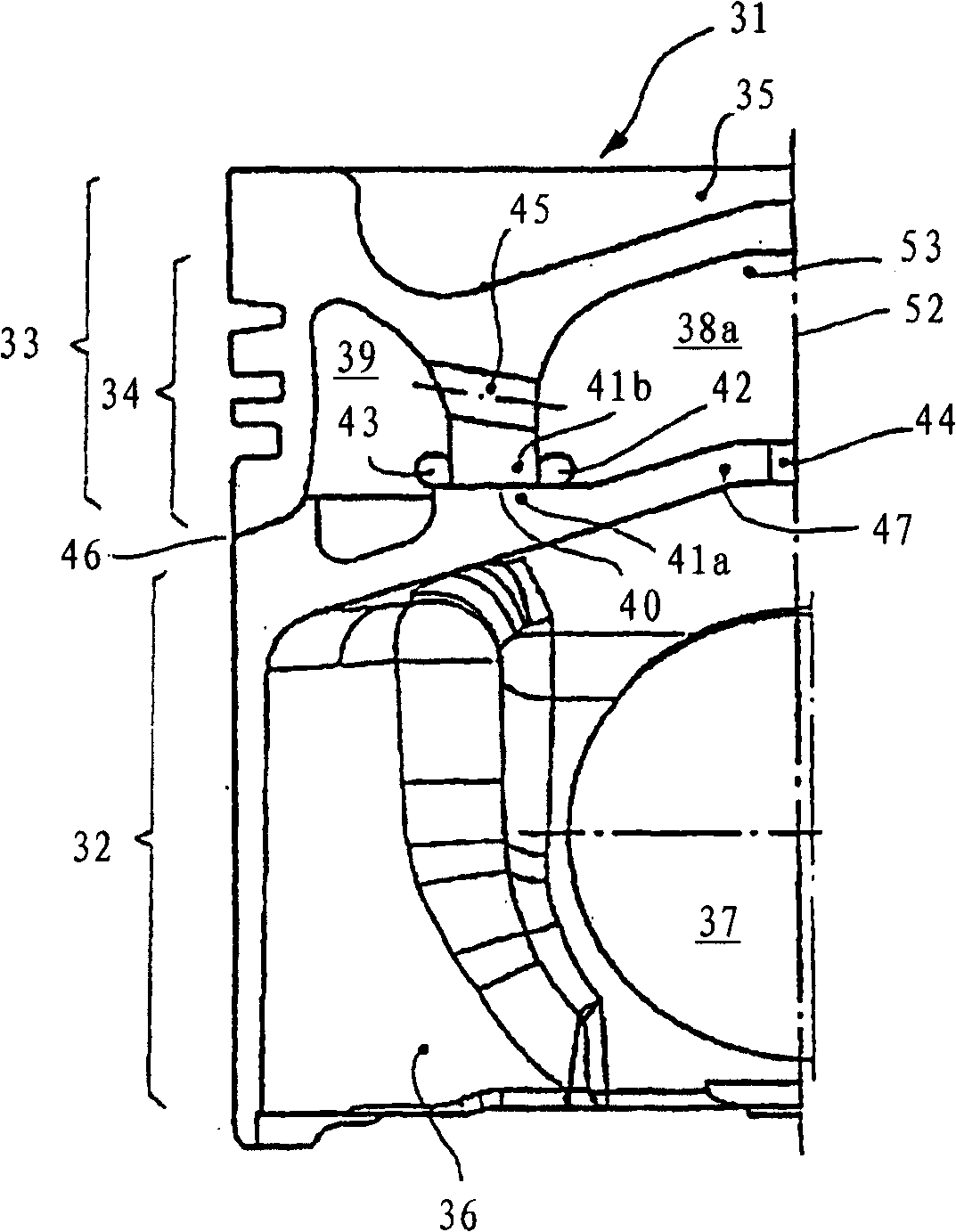

[0028] figure 1 and 2 A half-section of a piston 1 for an internal combustion engine, which is formed as a cooling channel piston and is formed from a lower part 2 and an upper part 3 , is shown in each case. Furthermore, the piston 1 comprises a ring zone 4 defined for three piston rings, a combustion chamber cavity 5 , a piston skirt and a piston pin seat bore 7 . After the lower part 2 and the upper part 3 have been joined together, the piston 1 forms an inner cooling channel 8 and an outer cooling channel 9 . At the same time, the lower part 2 and the upper part 3 are supported via joint surfaces 10 , 11 , 12 arranged offset from each other not only in the axial direction but also in the radial direction, which are joined together by means of friction welding to form composite parts, although other numbers of joint surfaces are also conceivable .

[0029]The weld clearly shows the weld projection 13 , 14 , 15 , 16 of each joint surface 10 , 11 , 12 pointing in the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com