Preparation of chloro-cyclohexane under nitrogen protection

A technology for the preparation of chlorocyclohexane, which is applied in the new process field of safe preparation of chlorocyclohexane, can solve the problems of increasing unsafe factors, and achieve the effect of preventing a series of chlorination reactions and ensuring selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with embodiment.

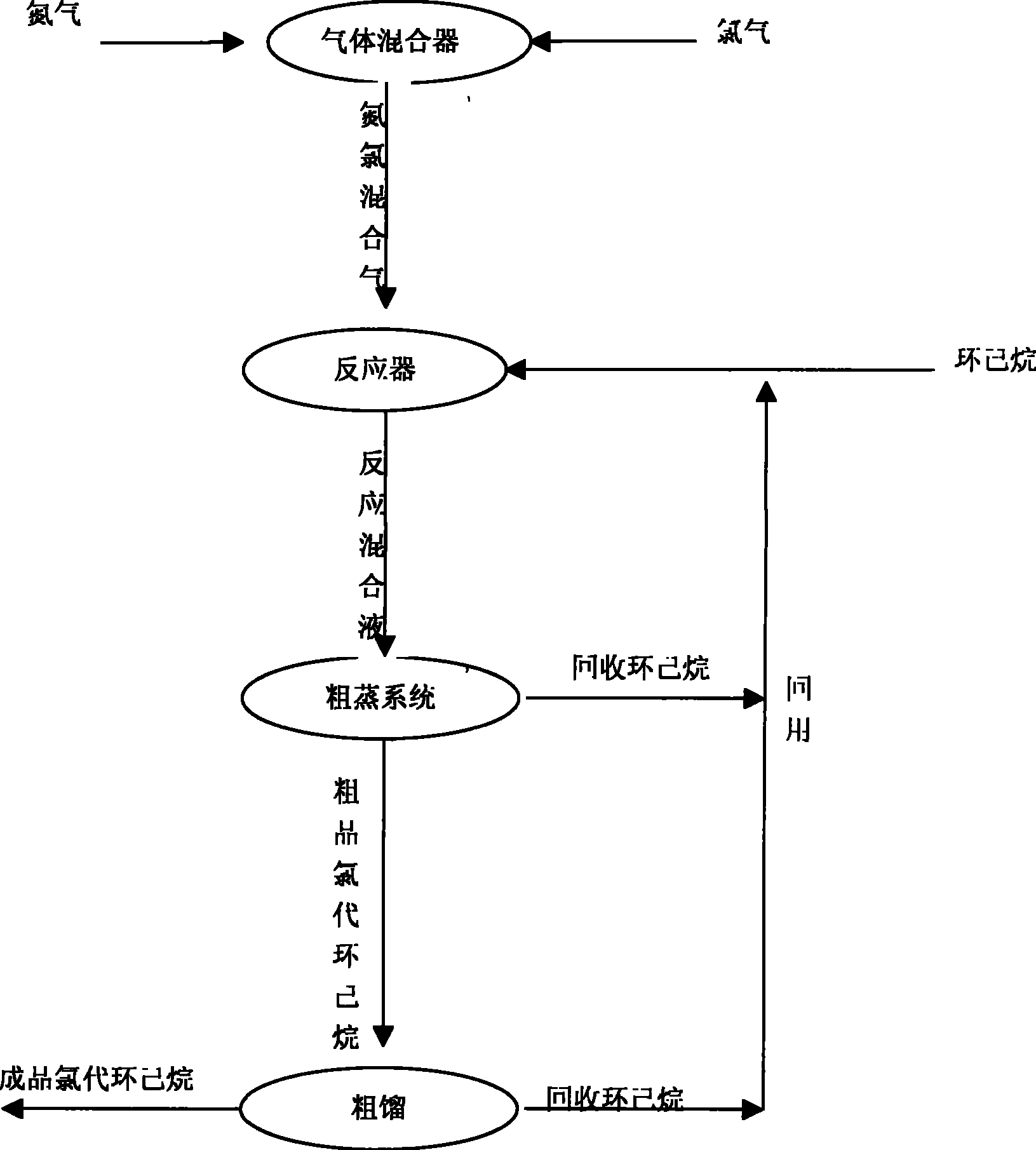

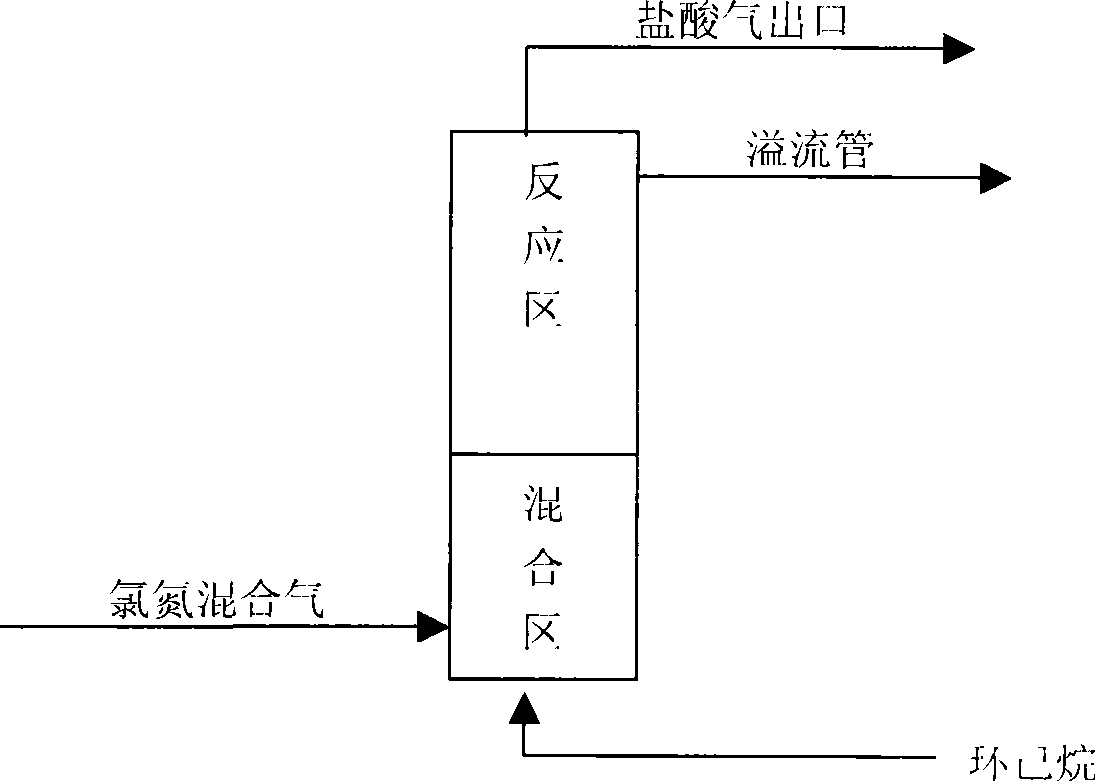

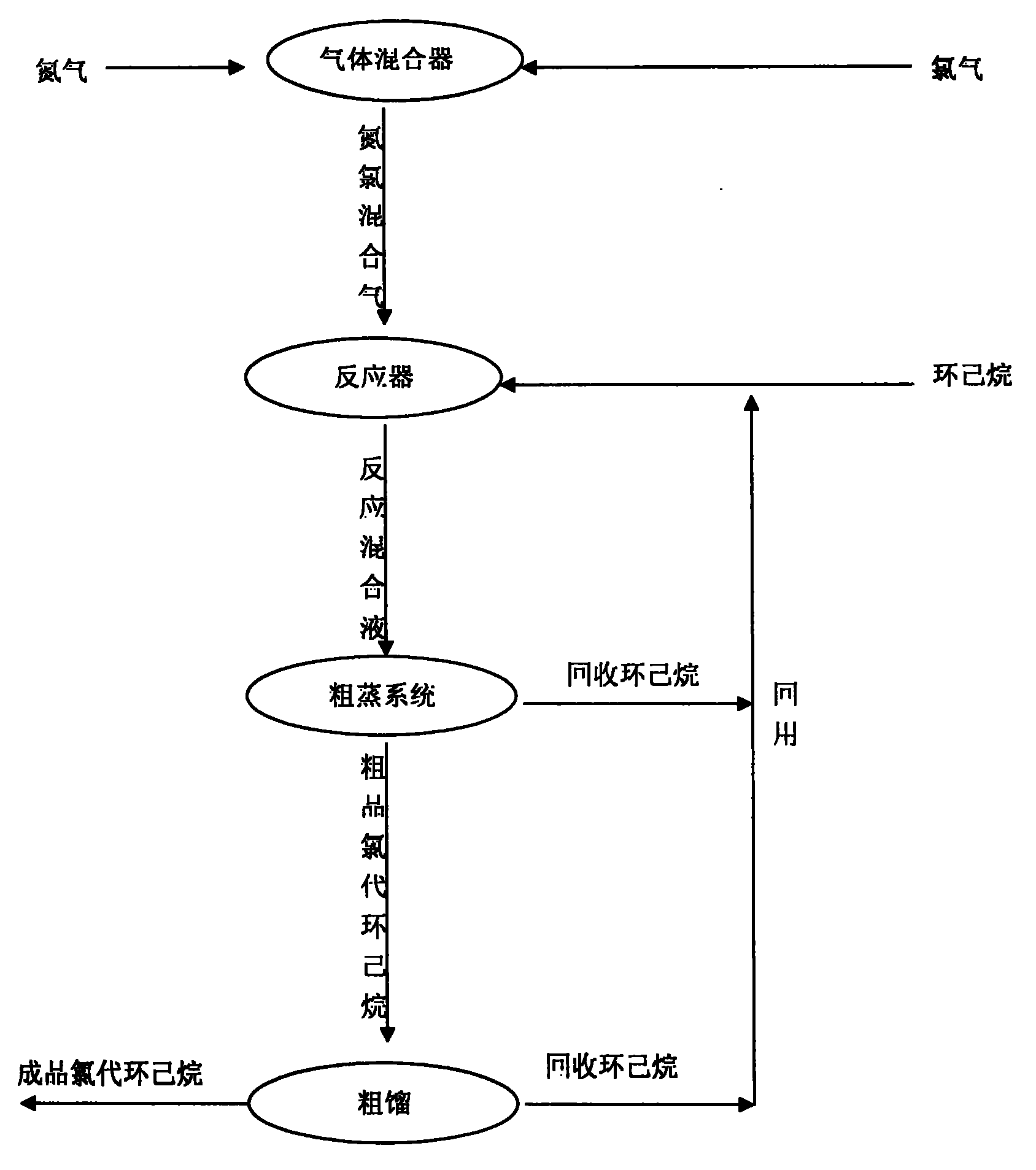

[0016] Continuously feed cyclohexane from the bottom port of the reactor at a rate of 320-340 L / h, open the steam valve to raise the temperature of the reactor to 50-60°C. Mix chlorine gas and nitrogen gas at a volume ratio of 1: (0.5 ~ 1) and then continuously feed it from the side port at the bottom of the reactor. Adjust the flow valve so that the feed rate of chlorine gas is 70 ~ 80 kg / h. After the chlorine gas is diluted with nitrogen, it is fully mixed with cyclohexane in the mixing zone at the lower part of the reactor, and reaches the reaction zone (upper part of the reactor) equipped with an initiating light source, and reacts rapidly under the initiating light to generate chlorocyclohexane alkyl. The fed nitrogen plays an important protective role in the system safety response. The generated chlorocyclohexane overflows from the overflow pipe in time and continuously enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com