Bicyclo oxazolidine tanning agent and method of preparing the same

A bicyclic oxazolidine tanning agent and a technology for the cyclooxazolidine tanning agent are applied in the field of bicyclic oxazolidine tanning agents and their preparation, which can solve the problems of environmental pollution, high cost and high selling price, and achieve strong operability, The effect of low production cost and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, add 65Kg of ethanolamine, 35Kg of formaldehyde, and 35Kg of ethylene glycol into a reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, and react at 57±3°C for 3 hours, then add 58Kg of glyoxal, and place it at a temperature of 68± React at 3°C for 5 hours, then vacuum dehydrate at 83±3°C for 2 hours, cool down to 43±3°C and discharge to obtain the product. The dehydration rate of the product is 93.5%, the hydrolyzed methylol content is 21.8%, and the aldehyde content is 21.1%.

Embodiment 2

[0032] First, add 115Kg of threonine, 25Kg of paraformaldehyde, and 75Kg of triethanolamine into a reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, and react at 68±3°C for 3 hours, then add 45Kg of acetaldehyde, and React at 72±3°C for 4 hours, then vacuum dehydration at 97±3°C for 4 hours, cool down to 52±3°C and discharge to obtain the product. The product has a dehydration rate of 90%, and a hydrolyzed methylol content of 13.8%.

Embodiment 3

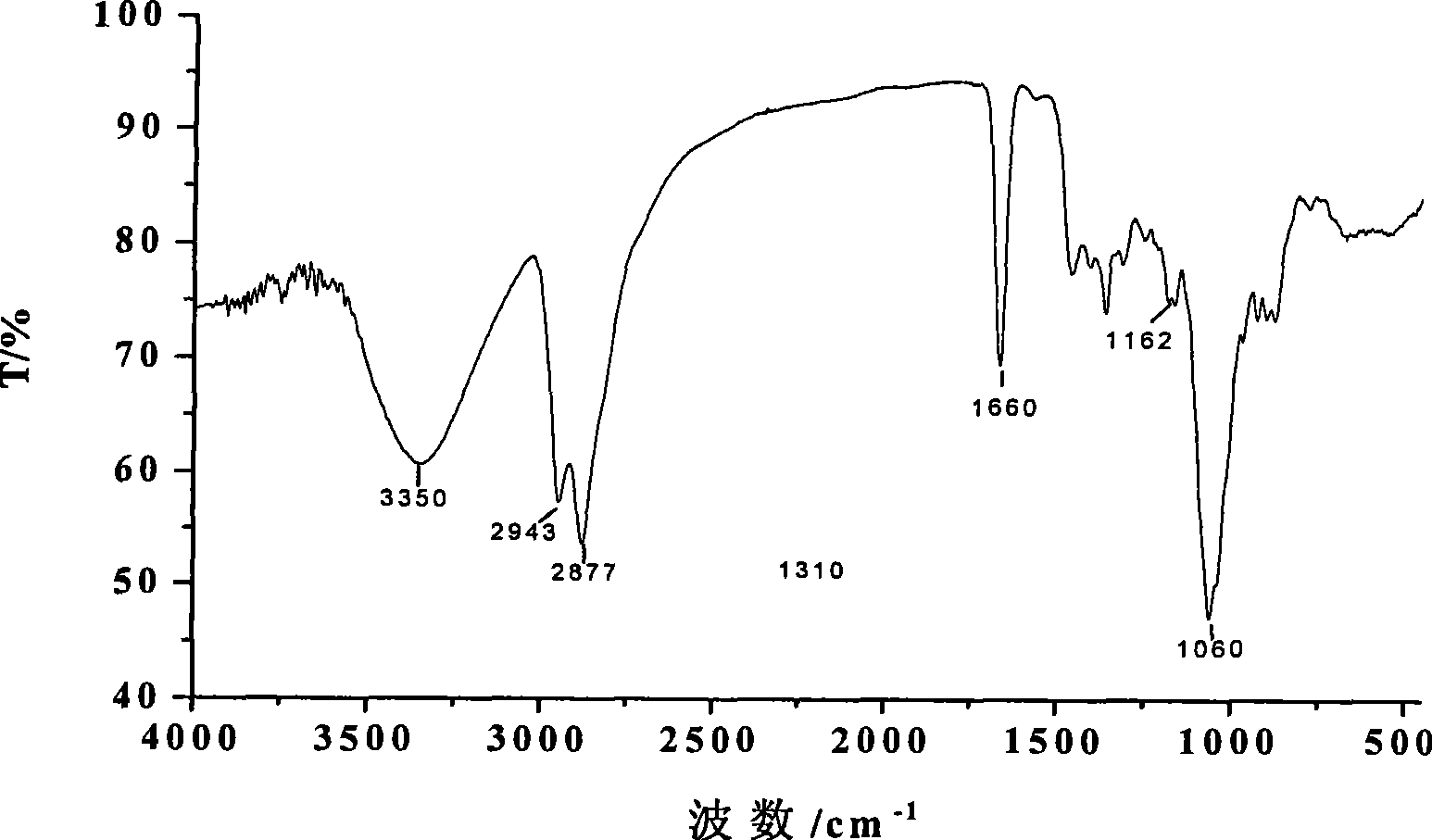

[0034] First, add 65Kg of ethanolamine, 105Kg of diethanolamine, and 90Kg of formaldehyde into a reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, and react at 63±3°C for 4 hours, then vacuum dehydration at a temperature of 88±3°C for 3 hour, cooled to 48±3°C and discharged to obtain the product. The dehydration rate of this product is 90.6%, and the hydroxymethyl content after hydrolysis is 41.2%. Its infrared spectrogram is as shown in the accompanying drawing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shrinkage temperature | aaaaa | aaaaa |

| Shrinkage temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com