Electric heating aluminum oxide ceramics heat pipe hot-blast stove

A kind of technology of alumina ceramics and heat pipe hot blast stove, which is applied in the direction of air heater, fluid heater, lighting and heating equipment, etc., can solve the problems of short service life, small gap, dry working medium, etc., and avoid high temperature oxidation and overheating The effects of burning damage, high thermal efficiency, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

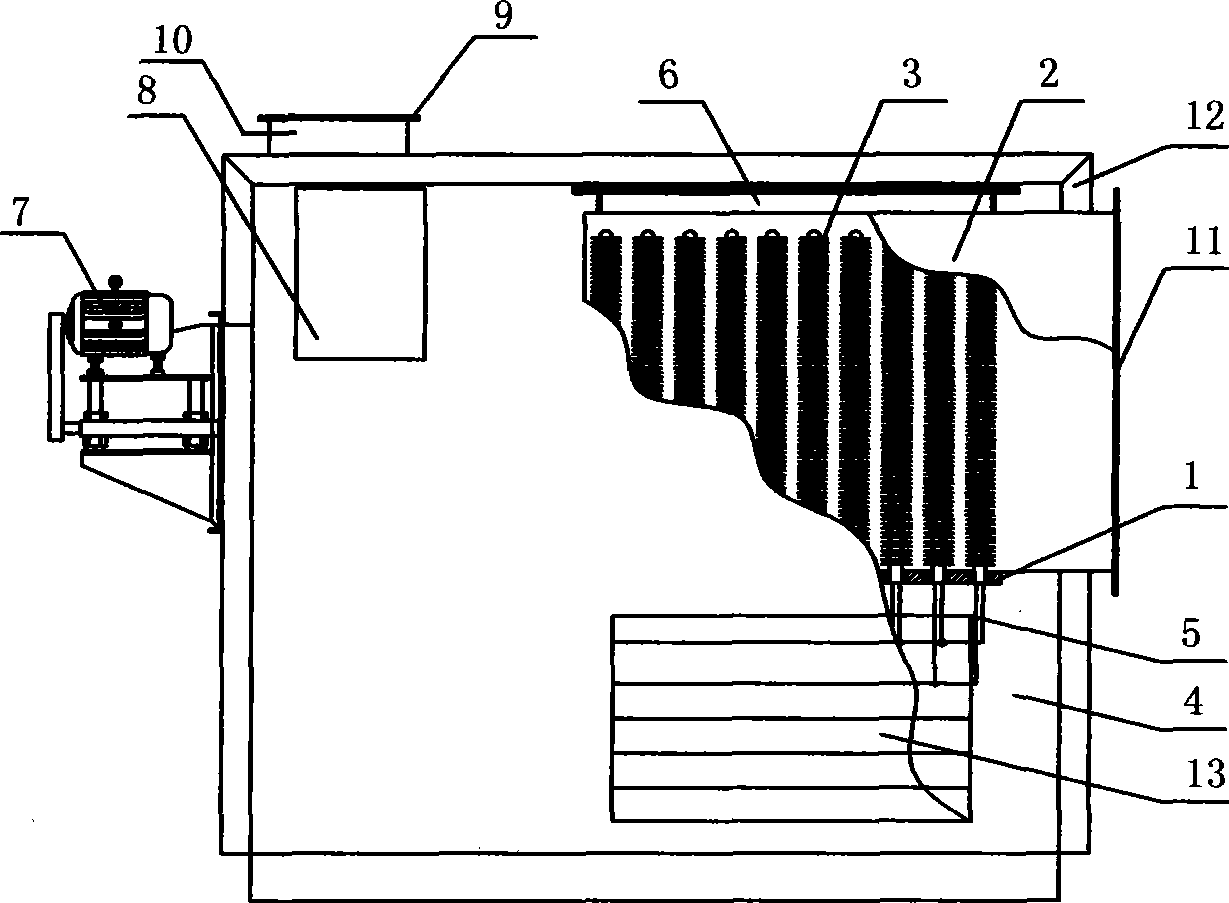

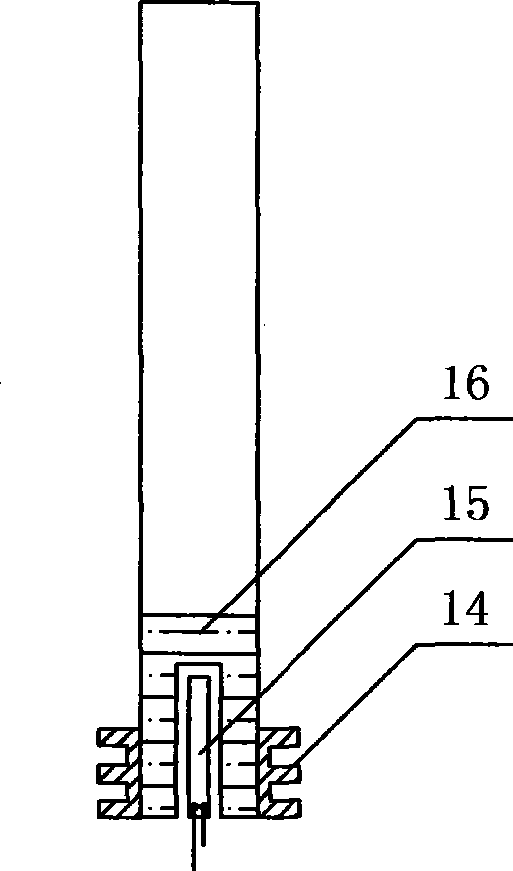

[0011] see figure 1 , figure 2 , start the power supply of the fan (7) on the automatic control box (8), start the power supply wiring room (4) and the wiring copper bar (5) to connect the electrothermal alumina ceramic fins fixed on the tube plate (1) by the snap ring (14) The electrothermal alumina ceramic heating sheet assembly (15) under the sheet heat pipe (3) heats the heat pipe working medium (16), and the working medium (16) absorbs heat, vaporizes, and heats up in high-speed phase conversion until it is placed on the top cover (6) The finned heat pipe (3) heat release section in the air heating chamber (2) releases heat to heat the air sucked by the fan (8) from the air inlet and outlet (11), and the heated air is heated by the hot air equipped with a temperature sensor (10). Exit (9) is discharged, and whole hot-blast stove is outsourced by outsourcing board (12), and grid sheet (13) is arranged to dissipate heat on both sides of power connection chamber (4).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com