Room temperature magnetic refrigeration working substance material and preparation thereof

A magnetic refrigeration and working fluid technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high cost and low magnetocaloric effect, and achieve improved magnetic moment density and magnetic domain density, high magnetocaloric effect, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Mn in this example 2.7 Fe 2.3 sn 3 The alloy formula is subjected to magnetic field forming and magnetic field sintering, and the process and steps are as follows:

[0026] (1) Firstly, the processed high-purity raw material Mn, Fe, Sn powder is replaced with Mn 2.7 Fe 2.3 sn 3 Carry out stoichiometric formula to obtain mixed powder, and ball mill the mixed powder with a ball-to-material ratio of 10:1 (mass ratio), add acetone to the ball mill tank to protect and disperse the particles, and pass high-purity argon gas into the protective atmosphere;

[0027] (2) Perform ball milling in a high-energy ball mill for 4 hours at a speed of 200 rpm. Take out the acetone and powder mixture and dry it under argon protection atmosphere to obtain fine Mn, Fe, Sn uniformly mixed powder;

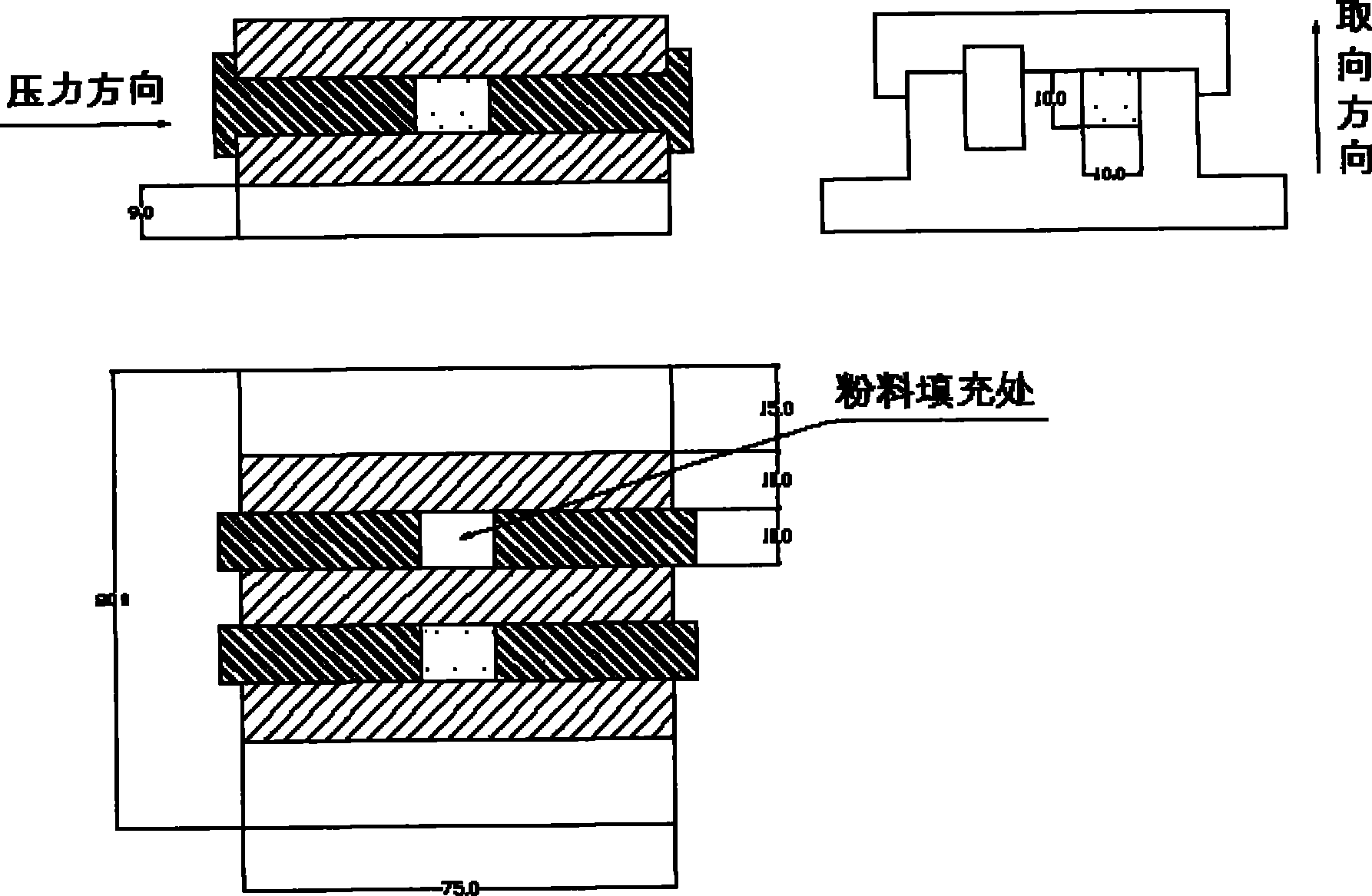

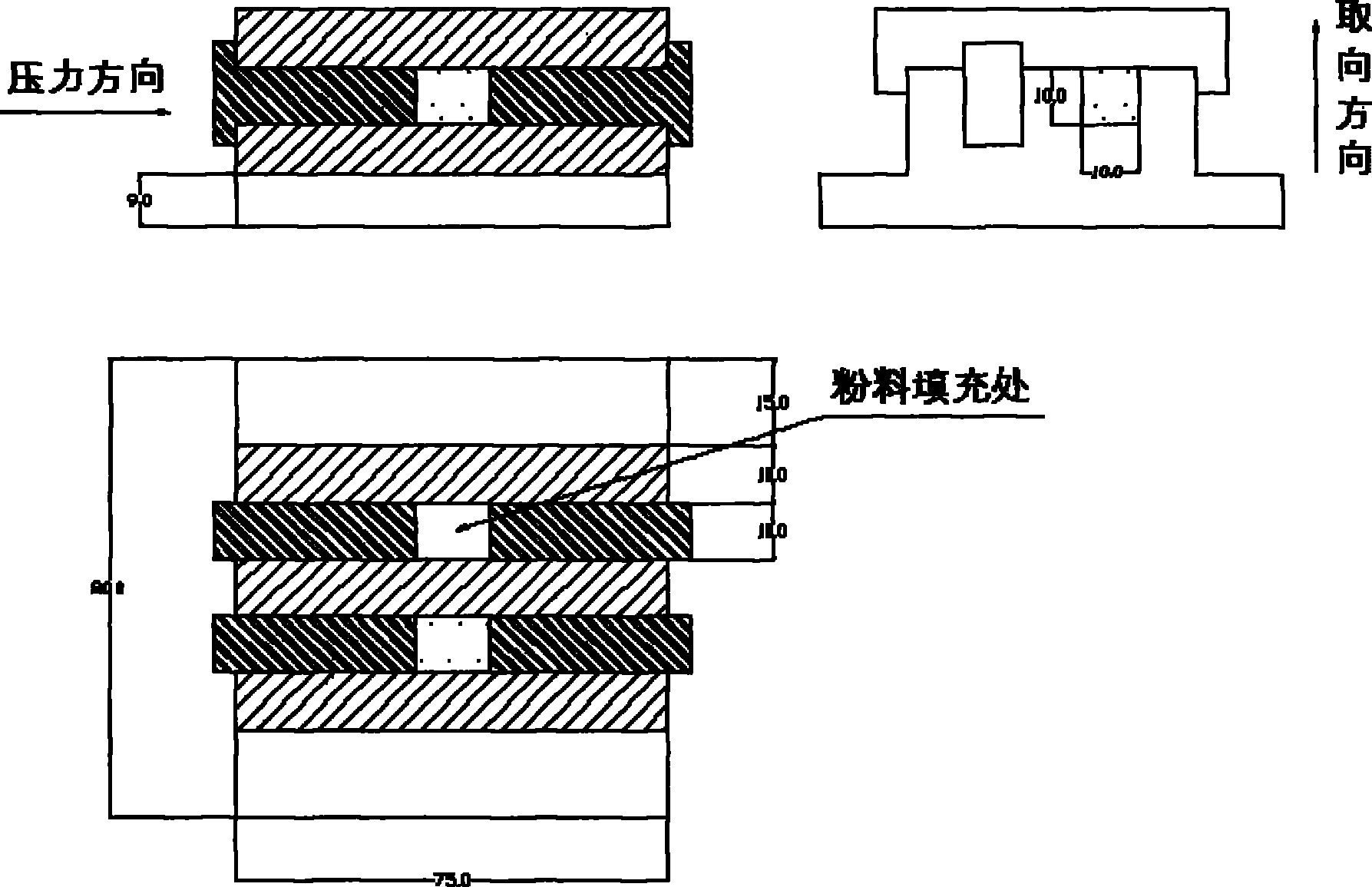

[0028] (3) the mixed powder of above-mentioned preparation is contained in the mold cavity with high magnetic permeability material (referring to figure 1 ), magnetization is carried out be...

Embodiment 2

[0031] In this example, Mn 3 Fe 2 sn 3 The alloy formula is subjected to magnetic field forming and magnetic field sintering, and the process and steps are as follows:

[0032] (1) Firstly, the processed high-purity raw material Mn, Fe, Sn powder is replaced with Mn 3 Fe 2 sn 3 Carry out stoichiometric formula, obtain mixed powder, carry out ball milling to this mixed powder, ball material ratio is 10: 1 (mass ratio), acetone is added in the ball mill jar to be used for protecting and dispersing particle, and pass into high-purity argon protective atmosphere;

[0033] (2) Perform ball milling in a high-energy ball mill for 4 hours at a speed of 200 rpm. Take out the acetone and powder mixture and dry it under argon protection atmosphere to obtain fine Mn, Fe, Sn uniformly mixed powder;

[0034] (3) the mixed powder of above-mentioned preparation is contained in the mold cavity with high magnetic permeability material (referring to figure 1 ), magnetization is carried ou...

Embodiment 3

[0037] In this example, Mn 3.6 Fe 1.4 sn 3 The alloy formula is subjected to magnetic field forming and magnetic field sintering, and the process and steps are as follows:

[0038] (1) Firstly, the processed high-purity raw material Mn, Fe, Sn powder is replaced with Mn 3.6 Fe 1.4 sn 3 Carry out stoichiometric formula to obtain mixed powder, and ball mill the mixed powder with a ball-to-material ratio of 10:1 (mass ratio), add acetone to the ball mill tank to protect and disperse the particles, and pass high-purity argon gas into the protective atmosphere;

[0039] (2) Perform ball milling in a high-energy ball mill for 4 hours at a speed of 200 rpm. Take out the acetone and powder mixture and dry it under argon protection atmosphere to obtain fine Mn, Fe, Sn uniformly mixed powder;

[0040] (3) the mixed powder of above-mentioned preparation is contained in the mold cavity with high magnetic permeability material (referring to figure 1 ), magnetization is carried out b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com