Middle arranging type planetary gear two-shift automatic speed variator

An automatic transmission, planetary gear technology, applied in the direction of gear transmission, belt/chain/gear, transmission, etc., can solve the problems of adverse effects of safe driving, small adaptation range, short continuation distance, etc. , Improve the transmission efficiency, the effect of smooth load changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

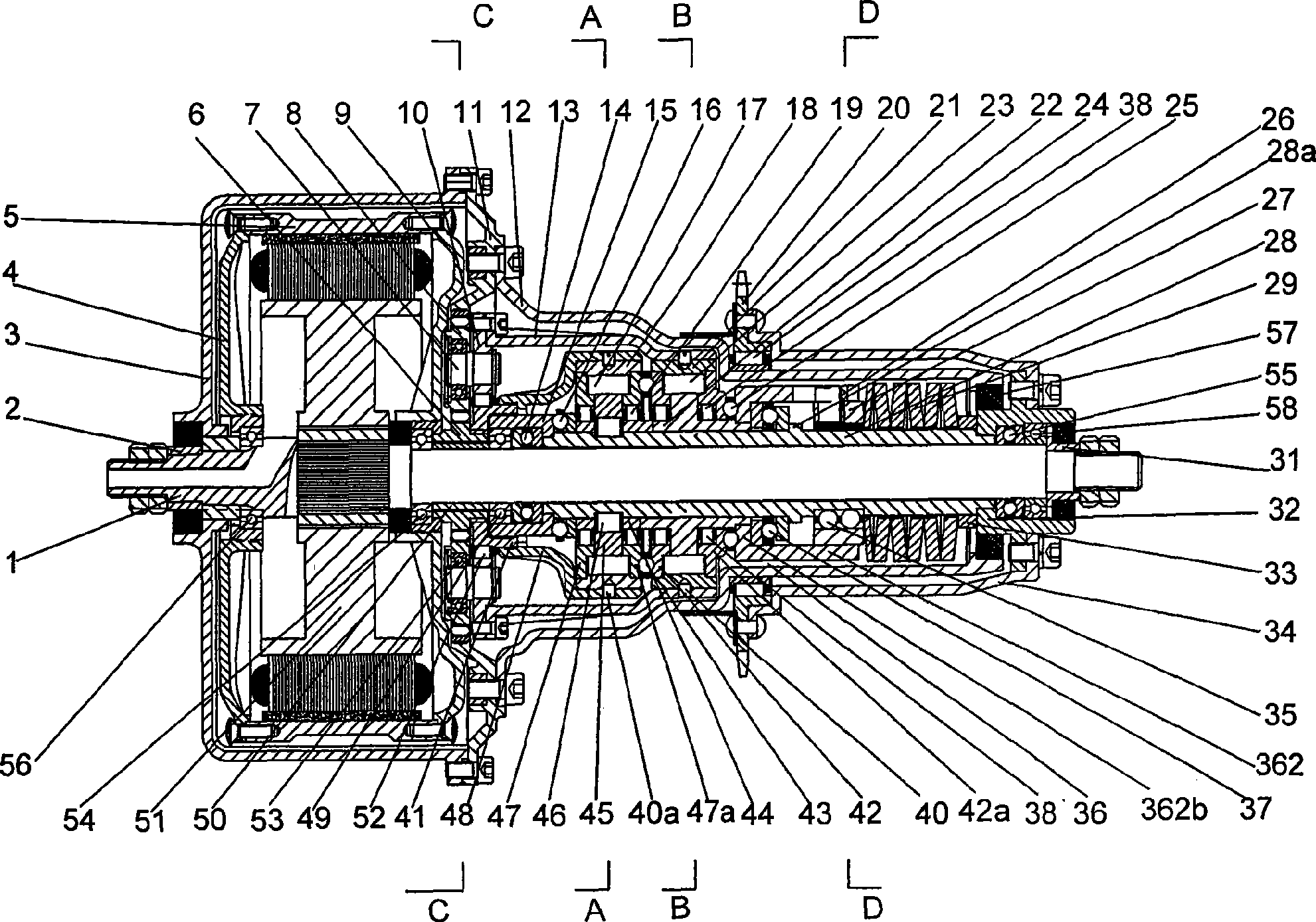

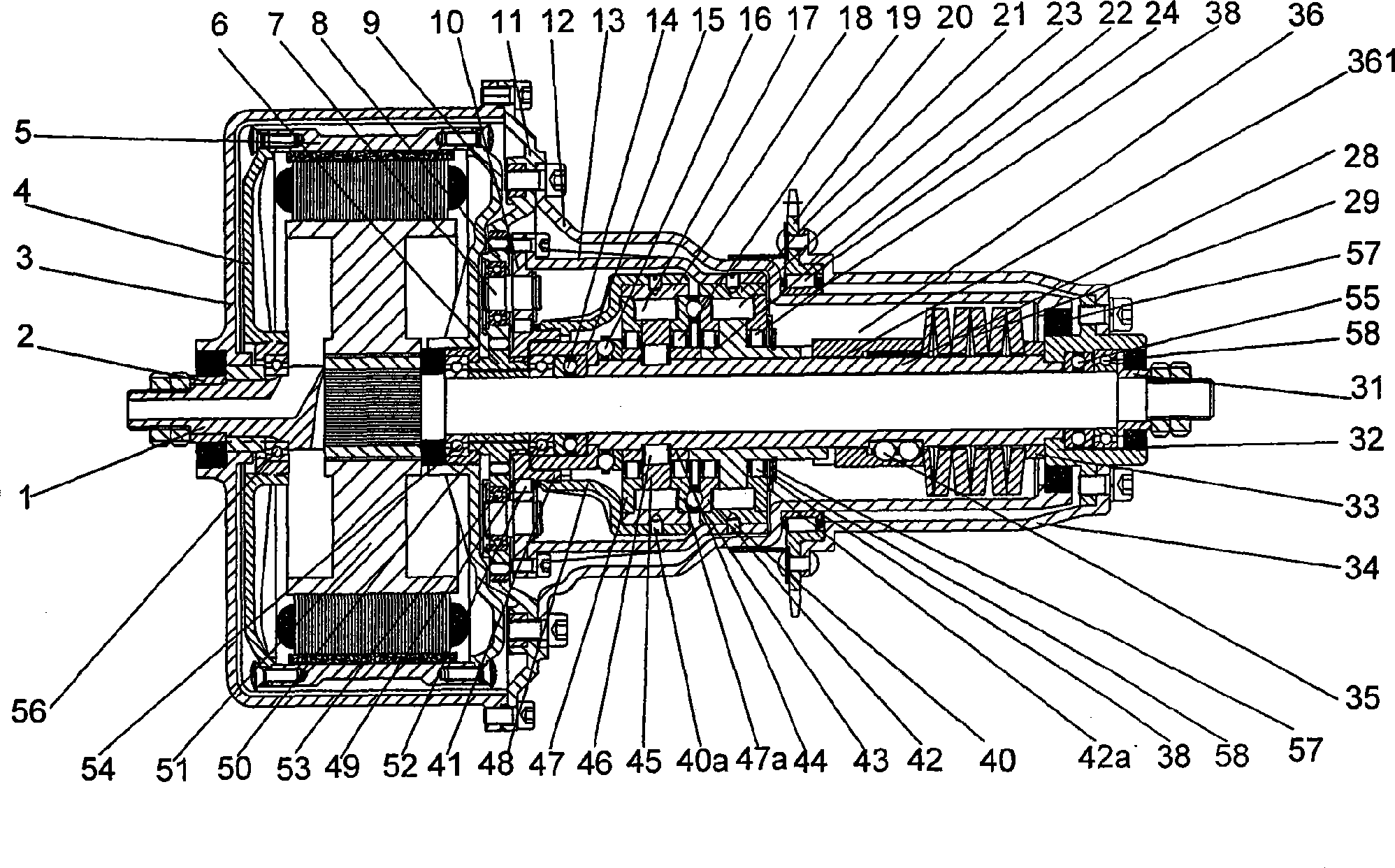

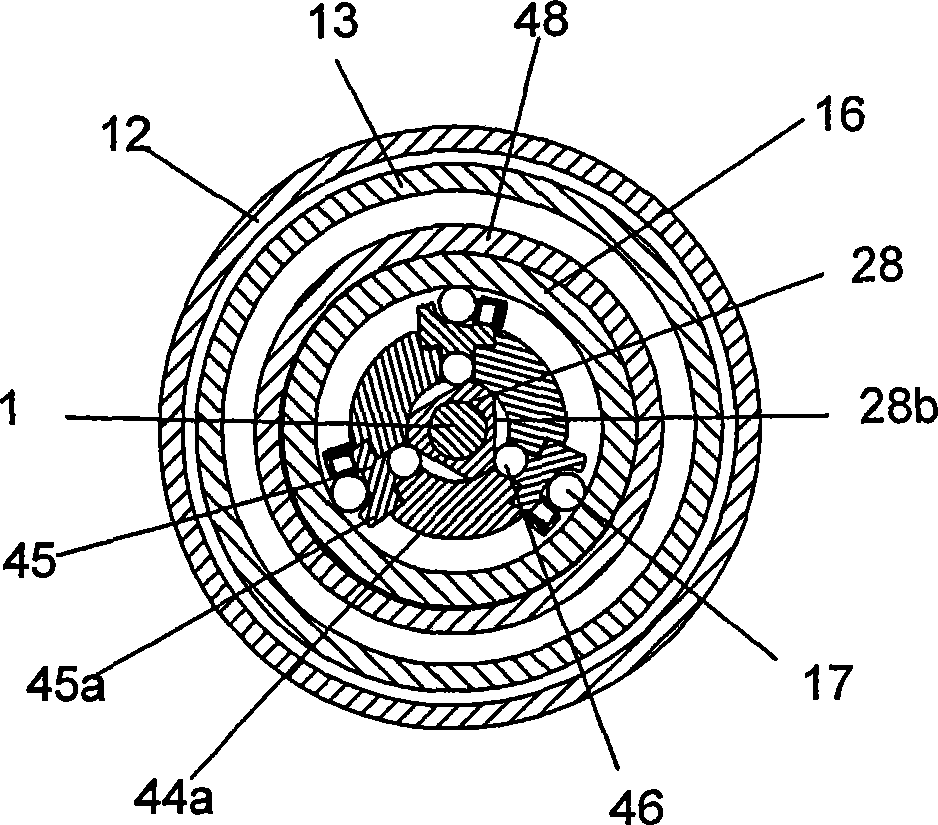

[0051] figure 1 It is a schematic diagram of the axial section structure of the present invention, as shown in the figure: the power equipment of this embodiment is a motor, which rotates clockwise when viewed from left to right during operation.

[0052] The center-mounted planetary gear two-speed automatic transmission includes a fixed shaft 1 fixedly arranged with the motor stator 51, a transmission shaft sleeve 28 sleeved on the fixed shaft 1 and rotatingly matched with the fixed shaft 1, and a power output sprocket fixedly connected with the transmission shaft sleeve 28 20. The fixed frame 3 fixedly connected to the left end of the fixed shaft 1 through the meshing shaft sleeve 2, the inner ring gear 11 arranged on the right end of the fixed frame 3 by screws, and the support sleeve 12 connected to the right end of the inner ring gear 11 by screws; The left end cover 4 and the right end cover 9 are respectively fixedly connected to both sides of the rotor 5 by screws, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com