Flocculant and preparation method thereof

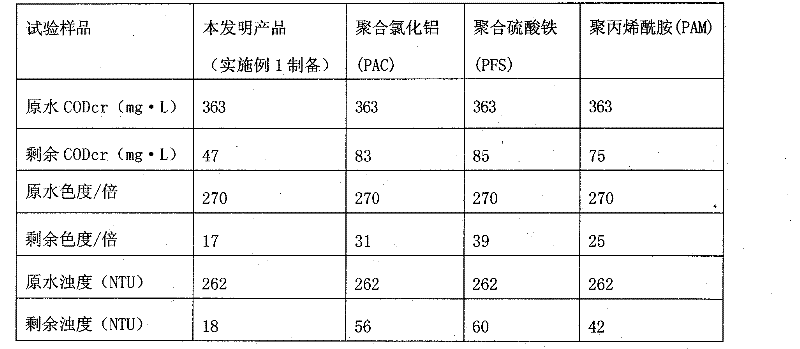

A flocculant and emulsifier technology, applied in the field of flocculant and its preparation, can solve the problems of poor water purification effect of flocculant, not environmental protection, etc., and achieve the effects of wide application range, improved water purification performance, and good water purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: First prepare cationic polyacrylamide: pour 6 parts (500g each, the same below) of acrylamide into the reaction kettle, then pour 120 parts of deionized water, stir until completely dissolved, then add 2 parts of Allyl dimethyl ammonium chloride, 0.2 parts of ammonium persulfate, controlled temperature at 85°C, and stirred for 1 hour to obtain cationic polyacrylamide for use.

[0016] Then prepare polysilicon aluminum ferric sulfate: dissolve 13 parts (500g each, the same below) of aluminum sulfate octadecahydrate in deionized water at a ratio of 1:2, and dissolve 13 parts of ferric sulfate hydrate in a ratio of 1:4 in In deionized water, then add aluminum sulfate solution and iron sulfate solution into the reaction kettle according to the weight ratio, control the temperature at 35°C, and add 18 parts of polysilicic acid with a pH value of 4 in turn under rapid stirring, 95 parts of deionized water and 5 parts of sodium hydroxide were stirred for 1 hour to o...

Embodiment 2

[0018] Example 2: First prepare cationic polyacrylamide: pour 15 parts (500g each, the same below) of acrylamide into the reaction kettle, then pour 150 parts of deionized water, stir until completely dissolved, then add 1 part of Allyl dimethyl ammonium chloride, 0.1 part of ammonium persulfate, the temperature is controlled at 75°C, and after stirring for 1 hour, a cationic polyacrylamide is obtained for use.

[0019] Then prepare polysilicon aluminum ferric sulfate: 21 parts (500g per part, the same below) of aluminum sulfate octadecahydrate are dissolved in deionized water in a ratio of 1:2, and 7 parts of ferric sulfate hydrate are dissolved in a ratio of 1:4 in In deionized water, then add aluminum sulfate solution and iron sulfate solution into the reaction kettle according to the weight ratio, control the temperature at 45°C, and add 10 parts of polysilicic acid with a pH value of 4 in turn under rapid stirring, 130 parts of deionized water and 2.5 parts of sodium hydr...

Embodiment 3

[0021] Example 3: First prepare cationic polyacrylamide: pour 10 parts (500g each, the same below) of acrylamide into the reaction kettle, then pour 135 parts of deionized water, stir until completely dissolved, then add 1.5 parts of Allyl dimethyl ammonium chloride, 0.3 parts of ammonium persulfate, the temperature is controlled at 75°C, and after stirring for 1 hour, a cationic polyacrylamide is obtained for use.

[0022] Then prepare polysilicon aluminum ferric sulfate: 17 parts (500g per part, the same below) of aluminum sulfate octadecahydrate are dissolved in deionized water in a ratio of 1:2, and 10 parts of ferric sulfate hydrate are dissolved in a ratio of 1:4 in In deionized water, then add aluminum sulfate solution and iron sulfate solution into the reaction kettle according to the weight ratio, control the temperature at 40°C, and add 15 parts of polysilicic acid with a pH value of 4 in turn under rapid stirring, 115 parts of deionized water and 4 parts of sodium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com