Ecological organic fertilizer and preparation method thereof

An organic fertilizer and eco-type technology, applied in the field of eco-type organic fertilizer, to achieve the effect of improving sustainable production capacity, convenient use and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

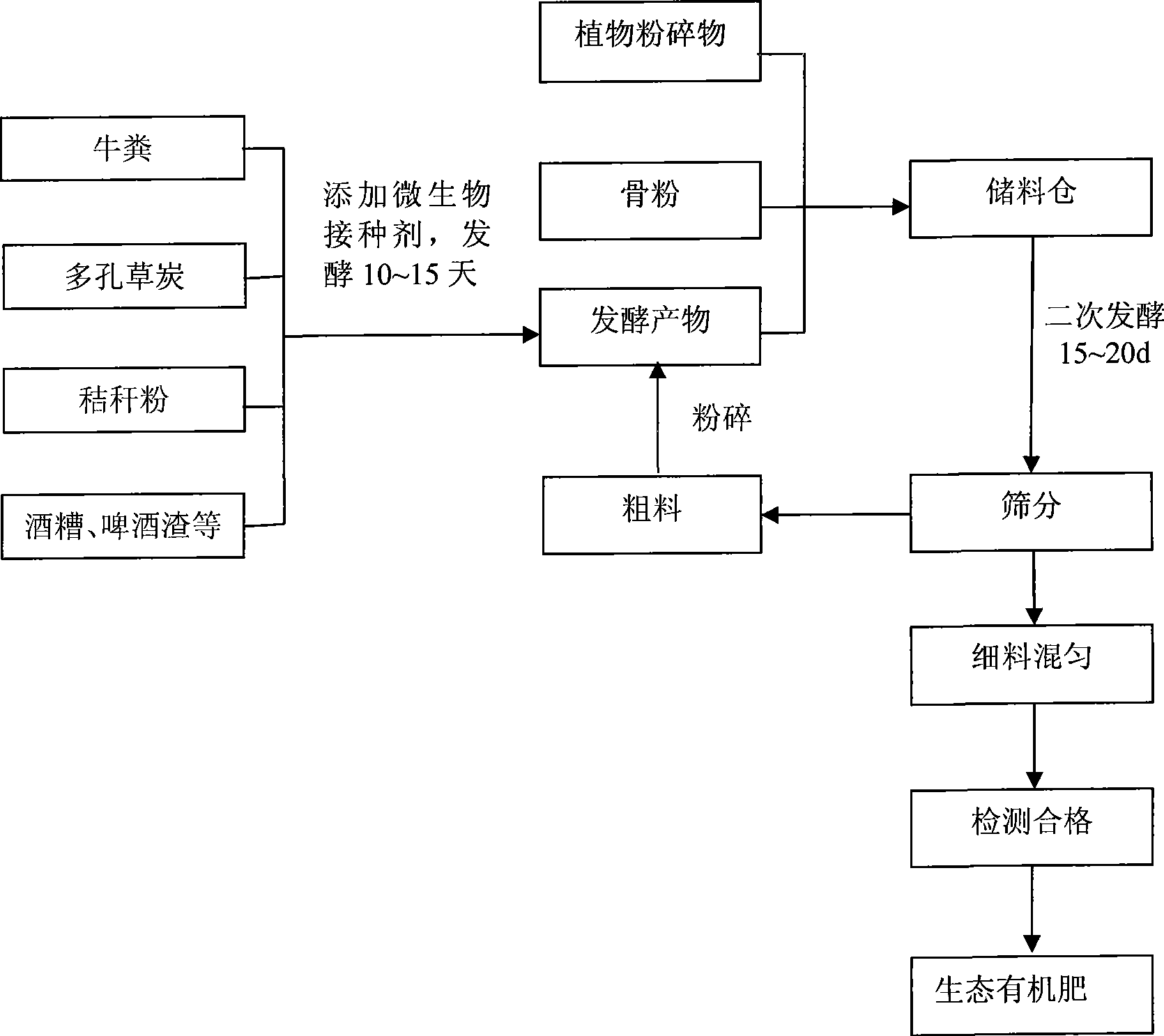

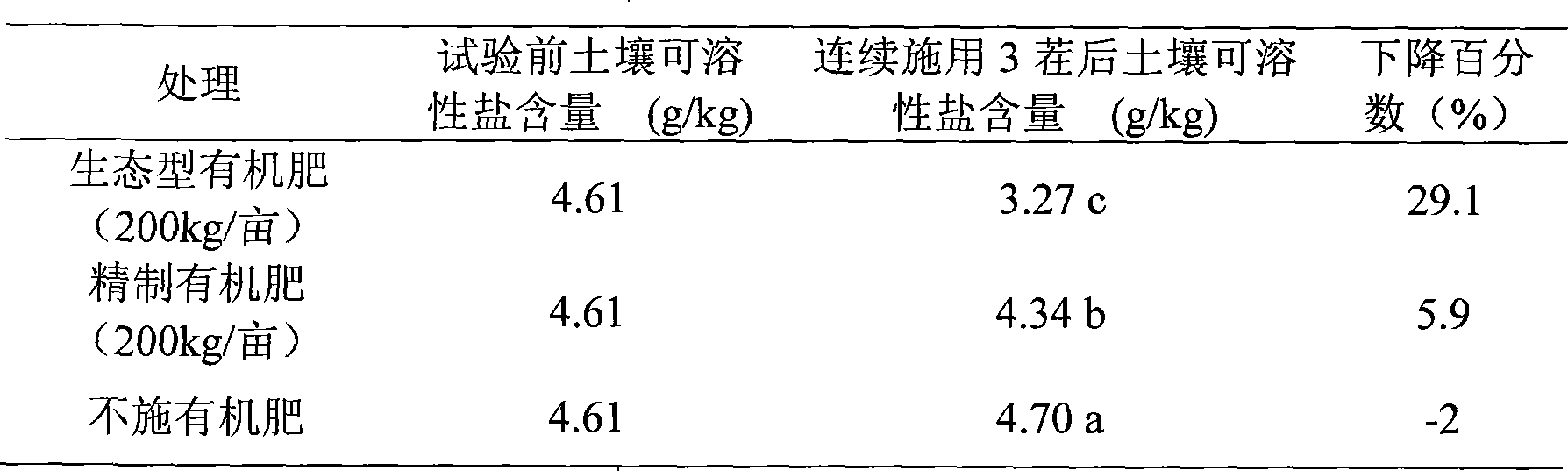

Method used

Image

Examples

Embodiment 1

[0049] Concrete steps and process conditions of the preparation process of the present invention are as follows:

[0050](1) Take 75% of cow dung with a moisture content of 70% (percentage by weight, the same below), 7% of porous peat, 10% of straw powder, and 8% of distiller's grains and mix them in proportion, adjust with urea, ammonium bicarbonate, lime nitrogen, etc. The C / N (mass ratio) of the compost material is 30:1, and the organic matter content of the compost material is adjusted to 60%. Then the compost material is transferred into a compost reactor, and 0.25% of VT-100 bacterial agent and 0.25% of VT-1000 bacterial agent are added to the total weight of the compost material. When the composting temperature rises to 50°C, the composting begins to be turned over every 5 days, and the cow dung fermentation product is formed after 15 days of composting.

[0051] (2) The crushed plant material is obtained by crushing the leaves and branches of the neem tree, and the bo...

Embodiment 2

[0053] (1) Take 60% of cow dung with a moisture content of 70% (percentage by weight, the same below), 5% of porous peat, and 10% of straw powder and mix them in proportion, and use urea to adjust the compost material C / N (mass ratio) to 30 : 1, the organic matter content of the compost material is adjusted to 45%. Then the compost material is transferred to a compost reactor, and 0.5% of the total weight of the compost material is added with an enzyme bacteria quick-rot agent. When the composting temperature rises to 50°C, the composting begins to be turned over every 5 days, and the cow dung fermentation product is formed after 10 days of composting.

[0054] (2) The crushed plant material is obtained from the leaves and branches of edamame, neem tree and neem tree, and the bone powder is obtained by crushing dried bovine bones, sheep bones and fish bones and passing through a 40-mesh sieve. Weigh 62% of the cow dung fermentation product, 8% of the crushed plants, and 30% o...

Embodiment 3

[0056] Concrete steps and process conditions of the preparation process of the present invention are as follows:

[0057] (1) Take cow dung 60% (percentage by weight, the same below) with a moisture content of 85%, porous peat moss 25%, straw powder 5%, distiller's grains 8%, beer dregs 2% and mix in proportion, and use urea, ammonium bicarbonate Adjust the C / N (mass ratio) of the compost material to 25:1, adjust the organic matter content of the compost material to 45%, and then transfer the compost material to the compost reactor. Add VT-100 bacterial agent accounting for 5% of the total weight of the compost material. When the compost temperature rises to 60°C, the compost starts to be turned over every 3 days, and the cow dung fermentation product is formed after 10 days of composting.

[0058] (2) The crushed plant material is obtained from the leaves and branches of edamame, neem tree and neem tree, and the bone powder is obtained by crushing dried fish bones and passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com