Water-soluble baking finish special for compressor and preparation method thereof

A water-soluble, compressor technology, applied in the chemical field, can solve the problems affecting the salt spray resistance of the paint film, the limitation of popularization and application, and the high content of carboxyl groups, so as to improve the salt spray resistance, improve the cross-linking degree of the paint film, and improve the salt spray resistance. The effect of fog performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

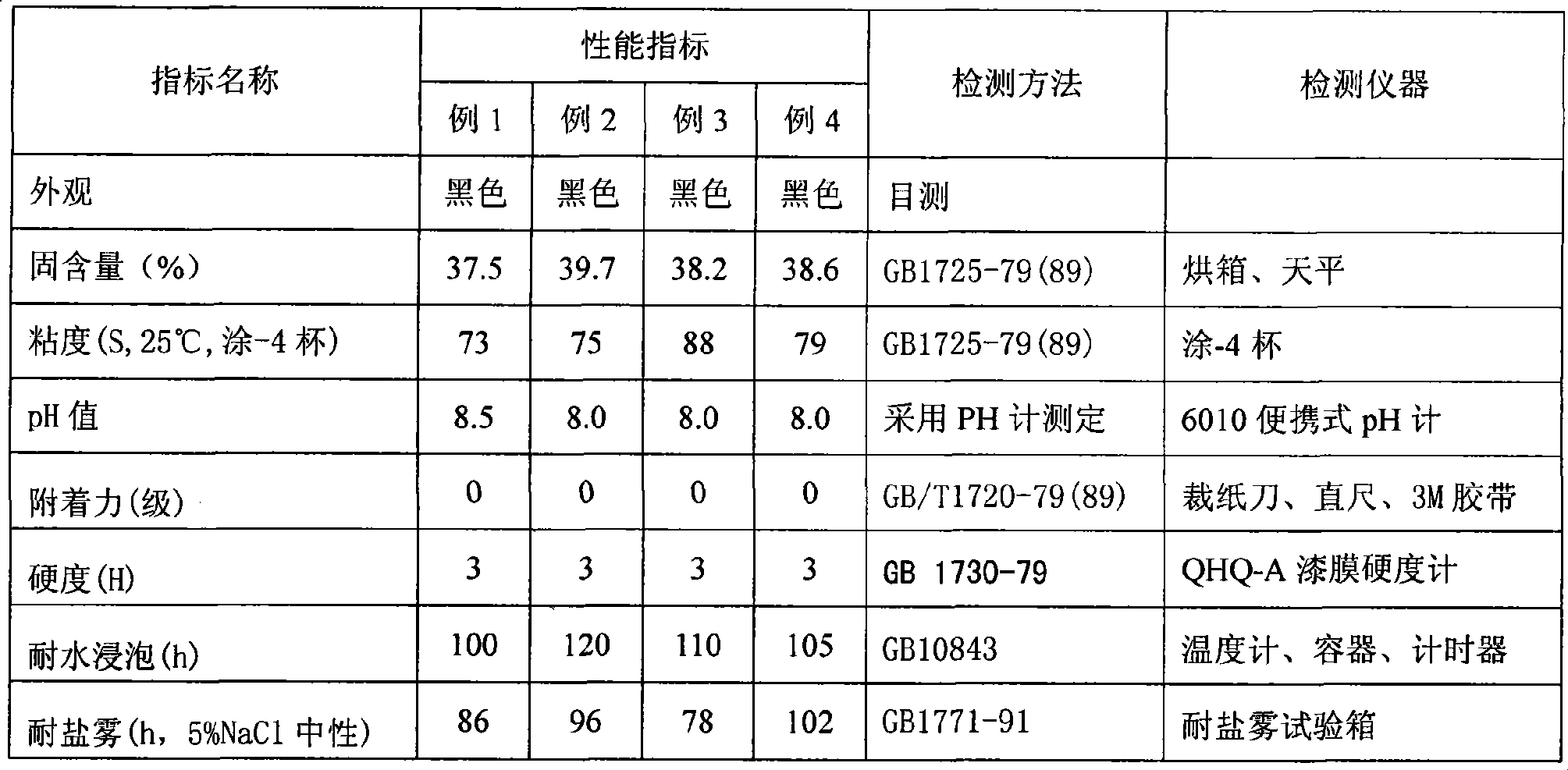

example 1

[0029] 1. Formula: 30.0kg water-soluble epoxy phosphate modified acrylic resin, 6.0kg methyl etherified melamine resin, 11.0kg zinc phosphomolybdate environmental protection anti-rust filler, 2.0kg carbon black, 0.3kg BYK-301 leveling agent, 0.5kg BYK-191 dispersing wetting agent, 0.1kg BYK-028 defoamer, 13.0kg propylene glycol methyl ether and 37.1kg water;

[0030] Among them, the preparation method of epoxy phosphate modified acrylic resin is: add 8.0kg of n-butanol and 4.0kg of epoxy resin to the reaction kettle, stir, heat to 110-120°C, add 1.6kg of phosphoric acid dropwise, and react 2- After 3 hours, cool down to 80-90°C, add 1.6kg of acrylic acid, 12.70kg of acrylic acid ester and 0.1kg of benzoyl peroxide mixture dropwise, react for 3-4 hours, and adjust the pH value to 7.5- 8.0 is fine.

[0031] 2. Preparation method: Take 23kg water-soluble epoxy phosphate modified acrylic resin, add 11.0kg zinc phosphomolybdate antirust filler, 2.0kg carbon black, 0.5kg BYK-191 di...

example 2

[0034] 1. Formula: 40.0kg water-soluble epoxy phosphate modified acrylic resin, 6.0kg butylated melamine resin, 13.0kg zinc phosphomolybdate anti-rust filler, 2.2kg carbon black, 0.6kg EFKA-323 siloxane leveling agent, 0.8kg BYK-192 dispersing wetting agent, 0.3kg HESNIC H221 defoamer, 10.0kg propylene glycol methyl ether and 27.1g water;

[0035] Among them, the preparation method of epoxy phosphate modified acrylic resin is: add 11.3kg of n-butanol and 4.5kg of epoxy resin to the reaction kettle, stir, heat to 110-120°C, add 1.6kg of phosphoric acid dropwise, and react 2- After 3 hours, cool down to 80-90°C, add 2.0kg of acrylic acid, 18.0kg of acrylic acid ester and 0.1kg of benzoyl peroxide mixture dropwise, react for 3-4 hours, and adjust the pH value to 7.5- 8.0 is fine.

[0036] 2. Preparation method: Take 27kg water-soluble epoxy phosphate modified acrylic resin, add 13.0kg zinc phosphomolybdate antirust filler, 2.2kg carbon black, 0.8kg BYK-192 dispersing wetting age...

example 3

[0039] 1. Formula: 33.0kg water-soluble epoxy phosphate modified acrylic resin, 10.0kg methyl etherified melamine resin, 15.5kg zinc phosphomolybdate antirust filler, 3.0kg carbon black, 1.0kg SF-1 dispersing wetting agent, 0.5kg PD-550 non-silicon defoamer, 12.0kg n-butanol and 25.0kg water;

[0040] Among them, the preparation method of epoxy phosphate modified acrylic resin is: add 8.2kg of n-butanol and 3.3kg of epoxy resin to the reaction kettle, stir, heat to 110-120°C, add 1.3kg of phosphoric acid dropwise, and react 2-3 After one hour, cool down to 80-90°C, add 1.7kg of acrylic acid, 16.5kg of acrylic acid ester and 0.1kg of benzoyl peroxide mixture dropwise, react for 3-4 hours, and adjust the pH value to 7.5-8.0 with 1.9 dimethylethanolamine That's it.

[0041]2. Preparation method: Take 26kg water-soluble epoxy phosphate modified acrylic resin, add 15.5kg zinc phosphomolybdate antirust filler, 3.0kg carbon black, 1.0kgSF-1 dispersing wetting agent, 0.3kg PD-550 def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com