Method for making gum code disc/code ruler

A production method and glue technology, applied in the production field of glue code discs/yardsticks, can solve the problems of inability to achieve high precision, low temperature resistance, good stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

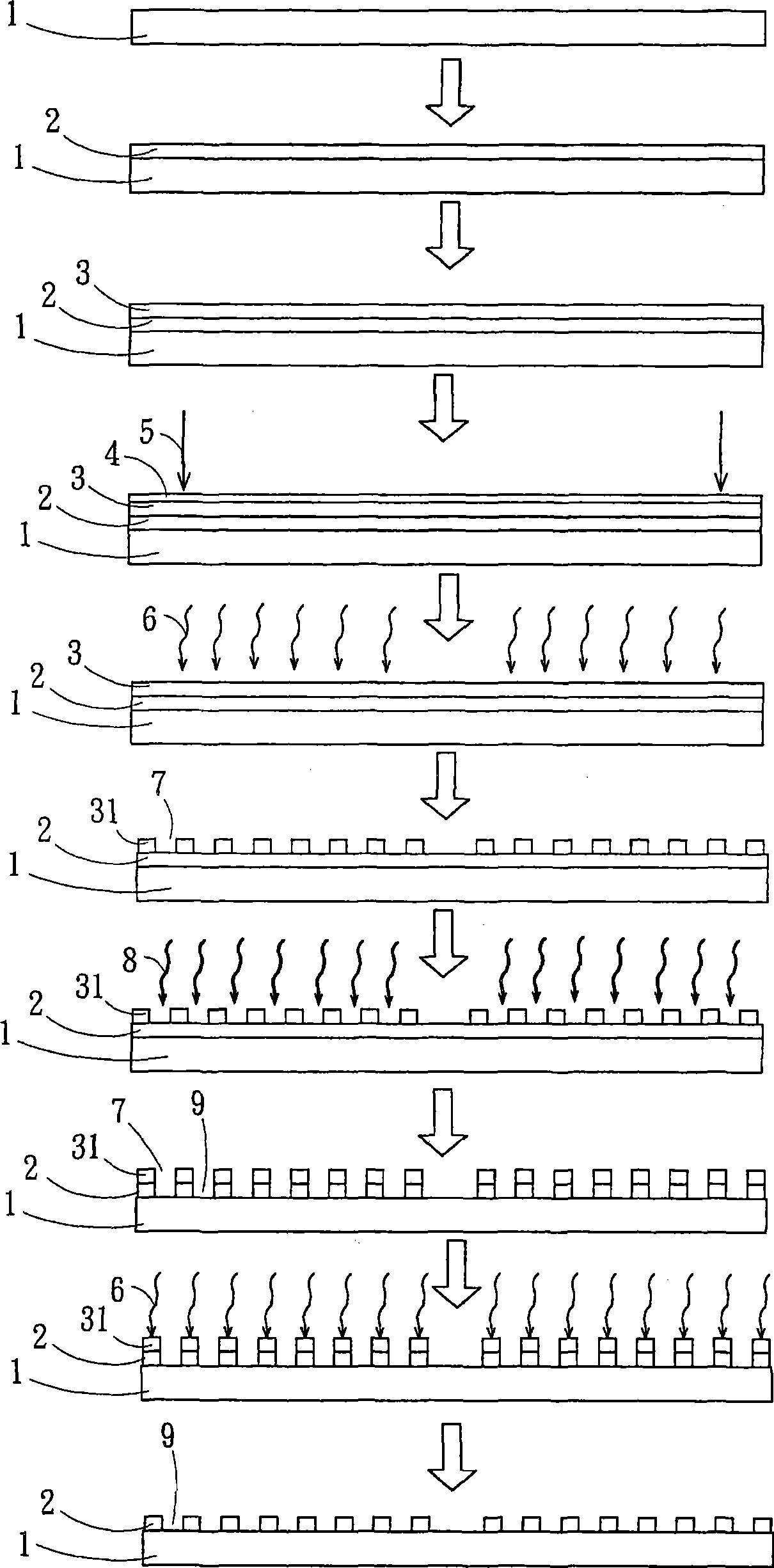

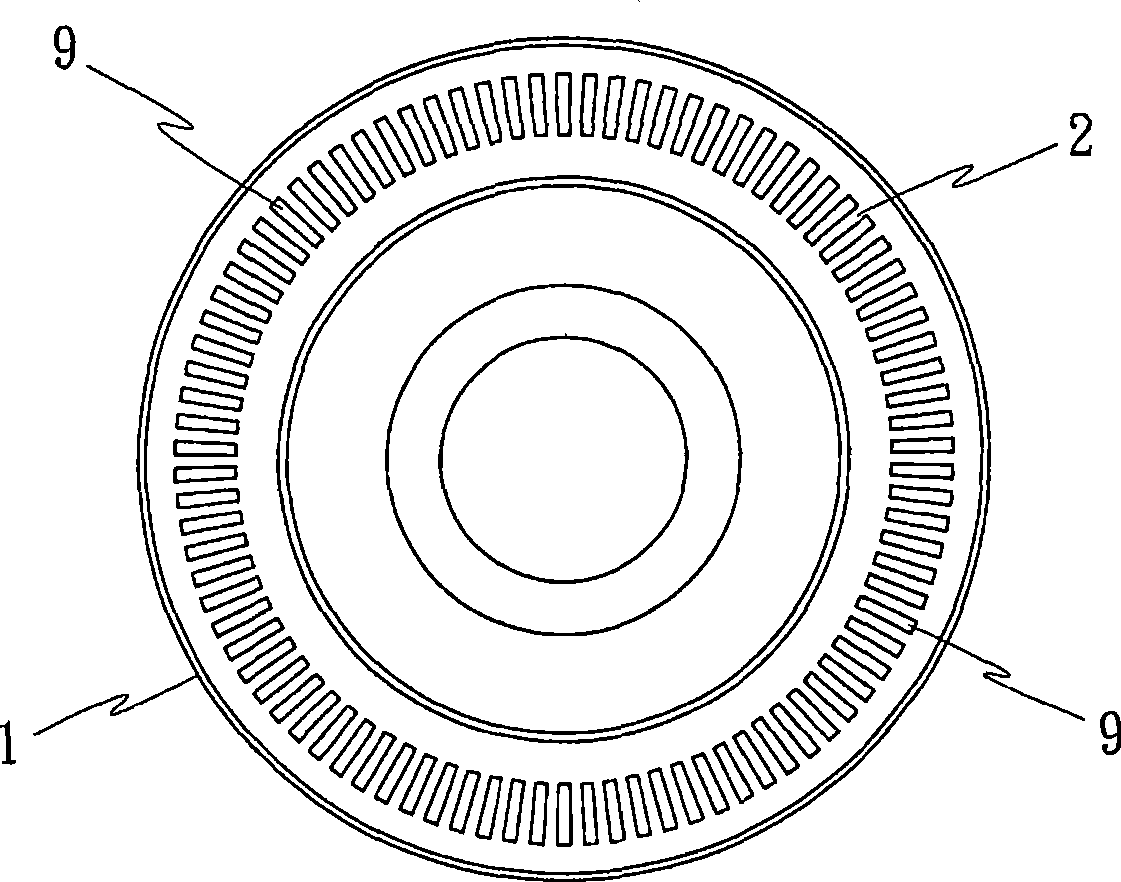

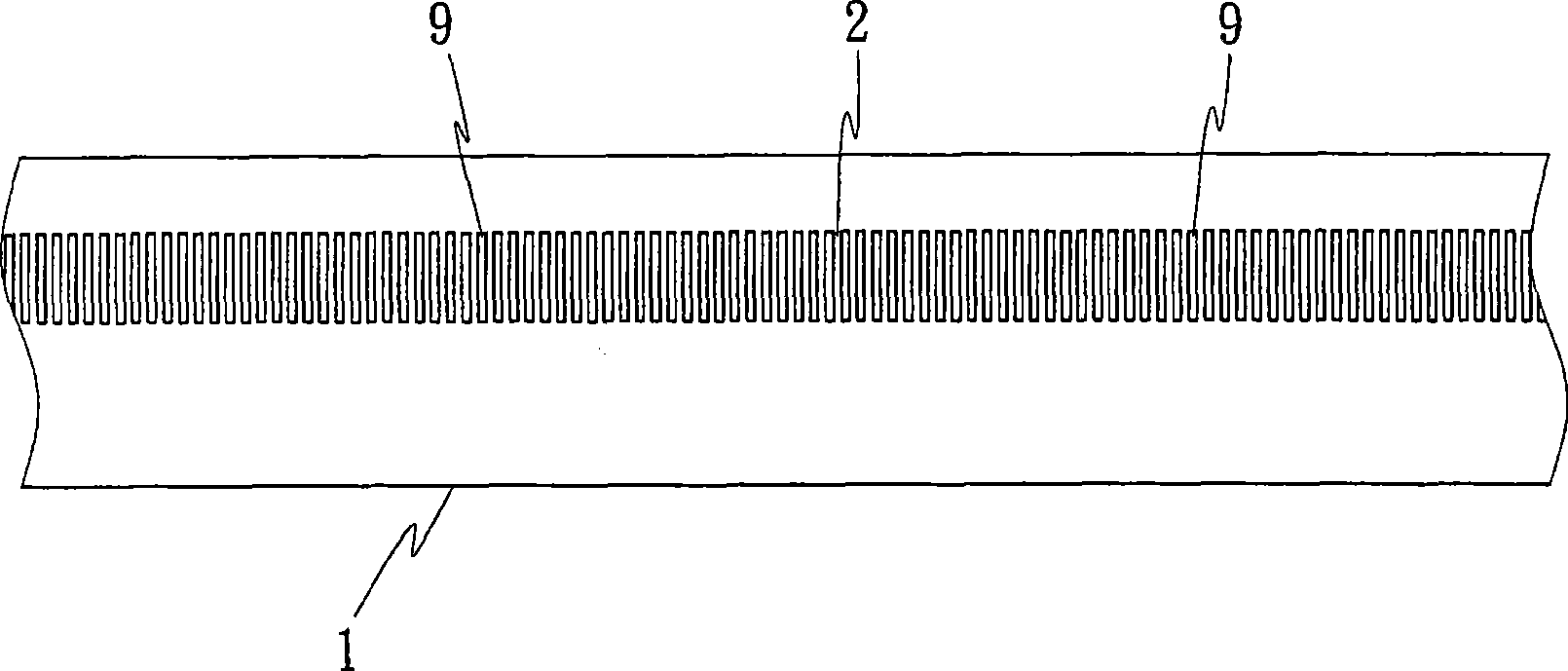

[0023] Such as figure 1 Shown is a manufacturing method of a colloidal code disc / code ruler according to the present invention; wherein the colloidal code disc is suitable for an encoder, and the colloidal code disc, commonly known as a scale, is suitable for an optical ruler. The colloidal code wheel / yardstick uses a colloidal plate 1 with a light transmittance of more than 90% and a high temperature resistance of up to 120°C as the base material. The colloidal plate 1 has a thickness of less than 0.5mm and is made of poly PET (PET: polyethylene terephthalate-polyethyleneterephthalate) or polycarbonate (PC: Polycarbonate) is better; because of its high temperature resistance, good hardness and easy processing material characteristics; first of all, glue A layer of chrome-aluminum film 2 with a thickness of less than 1 um is vapor-deposited on the surface of the quality plate 1, and then coated or sprayed with photoresist on the chrome-aluminum film 2 to form a layer of photor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com