Foam dedusting agent for mine

A dust-removing agent and foam technology, which is applied in the fields of dust prevention, mining equipment, fire prevention, etc., can solve the problems of late start of chemical dust suppressants, no in-depth research and field application, etc., and achieve simple processing, preparation and construction methods, and dust reduction. Long-lasting, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

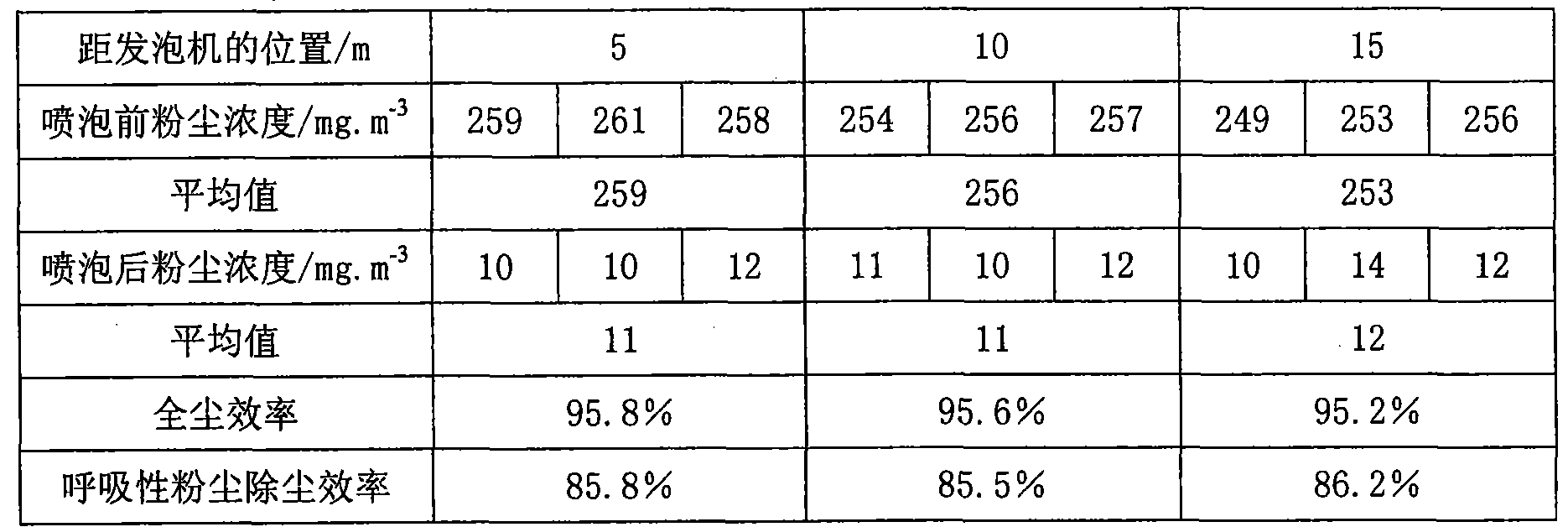

Embodiment 1

[0019] Take 12kg of sodium dodecylbenzenesulfonate, 5kg of sodium succinic acid diester sulfonate, 5kg of coconut oil diethanolamide, 0.2kg of carboxymethyl starch, 0.4kg of formaldehyde, and 1kg of urea into 76.4kg of water. Stir fully for 20-30 minutes to make 100kg foam dust remover. In the dust remover, the content of sodium dodecylbenzene sulfonate is 12%, sodium succinate diester sulfonate is 5%, coconut oil diethanolamide is 5%, carboxymethyl starch is 0.2%, and formaldehyde is 0.4% %, urea is 1%, and water is 76.4%. In order to reduce the stirring time, it can be stirred into a high-concentration solution, and then diluted with water to the required ratio. After the raw material components are completely dissolved, the foam dust remover is prepared. The prepared foam dedusting agent can be loaded into the foaming device for foaming operation. The dust removal rate of the foam dust remover with this formula reaches 95.67% for the whole dust and 85.64% for the respira...

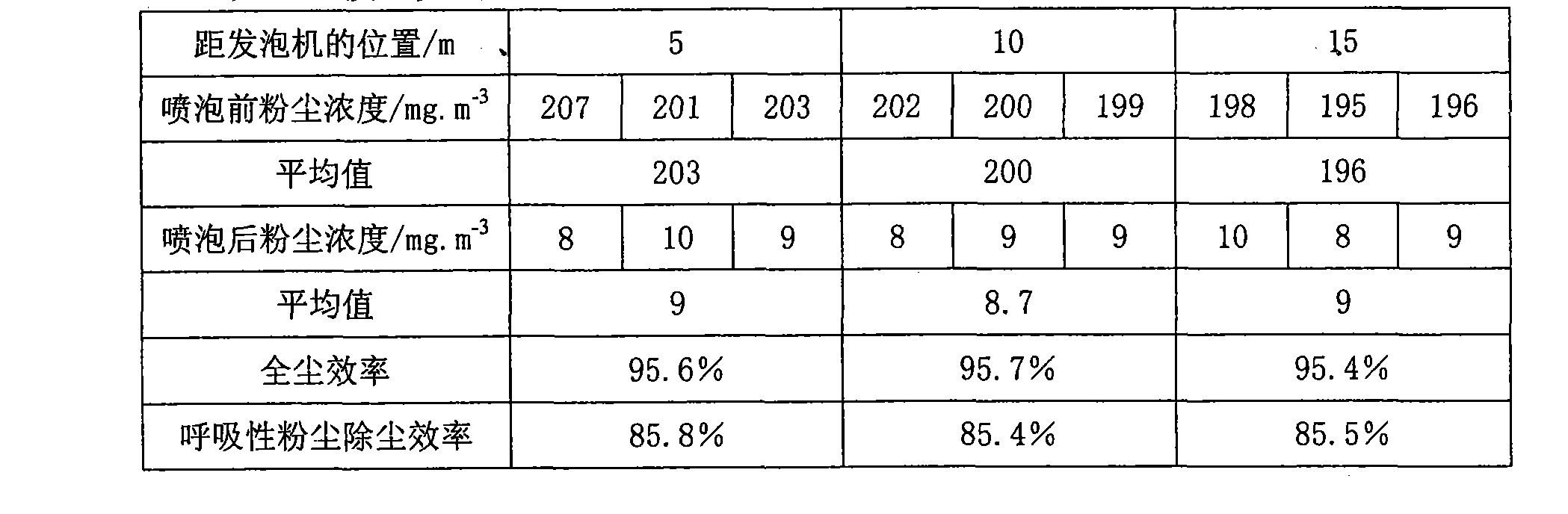

Embodiment 2

[0021] Take 18kg of sodium dodecylbenzenesulfonate, 3kg of sodium succinic acid diester sulfonate, 4kg of coconut oil diethanolamide, 0.3kg of carboxymethyl starch, 0.2kg of formaldehyde, and 1.5kg of urea into 73kg of water. Stir fully for 20-30 minutes to make 100kg foam dust remover. In the dust remover, the content of sodium dodecylbenzene sulfonate is 18%, sodium succinate diester sulfonate is 3%, coconut oil diethanolamide is 4%, carboxymethyl starch is 0.3%, formaldehyde is 0.2 %, urea is 1.5%, and water is 73%. Others are the same as embodiment 1. The dust removal rate of the foam dust remover with this formula reaches 95.81% for the whole dust and 85.79% for the respirable dust.

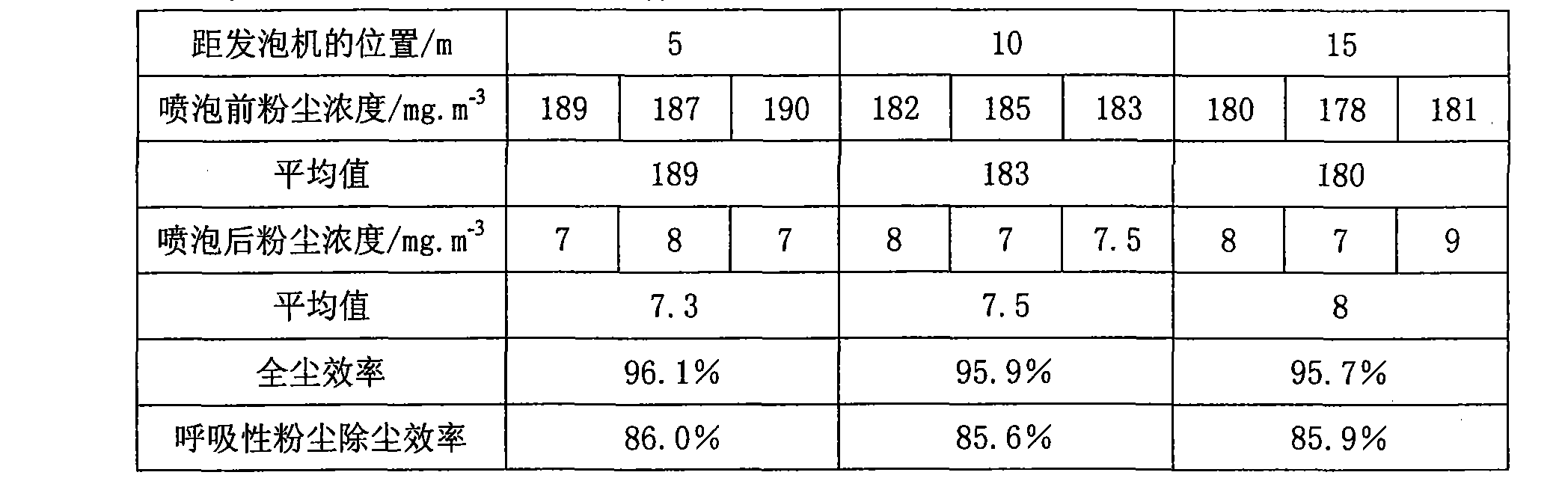

Embodiment 3

[0023] Get 16kg of ammonium dodecylbenzenesulfonate, 4kg of sodium succinic acid diester sulfonate, 5kg of coconut oil diethanolamide, 0.3kg of carboxymethyl starch, 0.3kg of formaldehyde, and 1.6kg of urea into 72.8kg of water. Stir fully under the pressure for 20-30 minutes to make 100kg foam dust remover. In the dust remover, the content of ammonium dodecylbenzene sulfonate is 16%, sodium succinate diester sulfonate is 4%, coconut oil diethanolamide is 5%, carboxymethyl starch is 0.3%, and formaldehyde is 0.3% %, urea is 1.6%, and water is 72.8%. Others are the same as embodiment 1. The dust removal rate of the foam dust remover with this formula reaches 95.21% for the whole dust and 85.08% for the respirable dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com