Method for preparing organosilicon emulsion containing elastomer polysiloxane with quaternary ammonium radical

A technology of silicone emulsion and quaternary ammonium group, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., and can solve problems such as reduced combing force and unsatisfactory silicone emulsions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

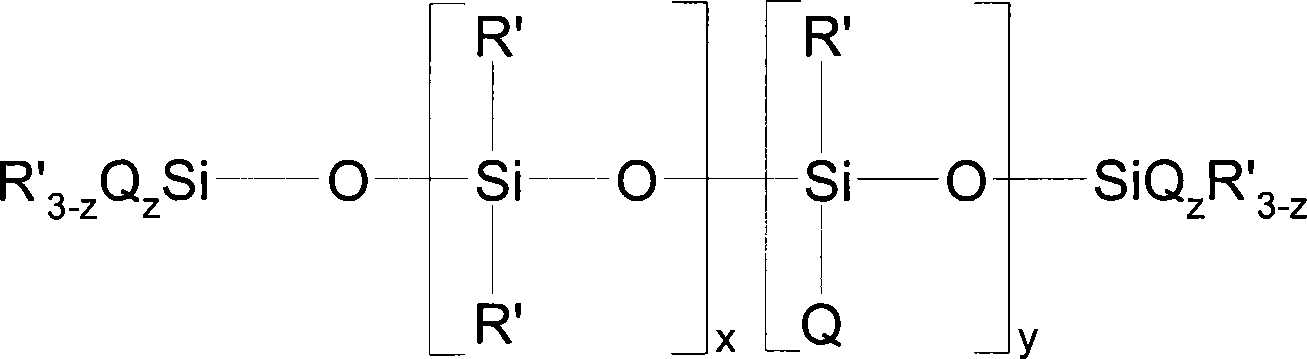

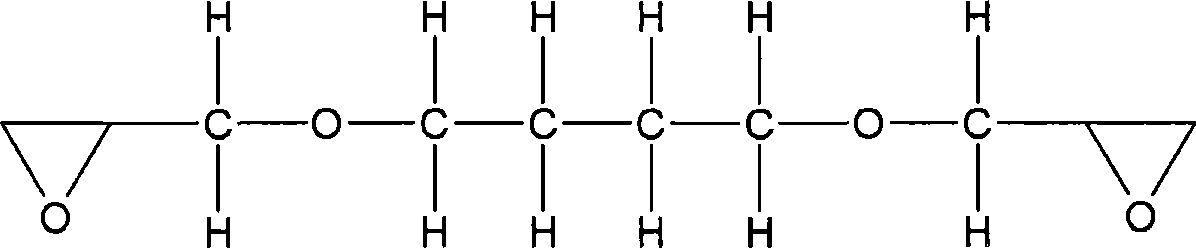

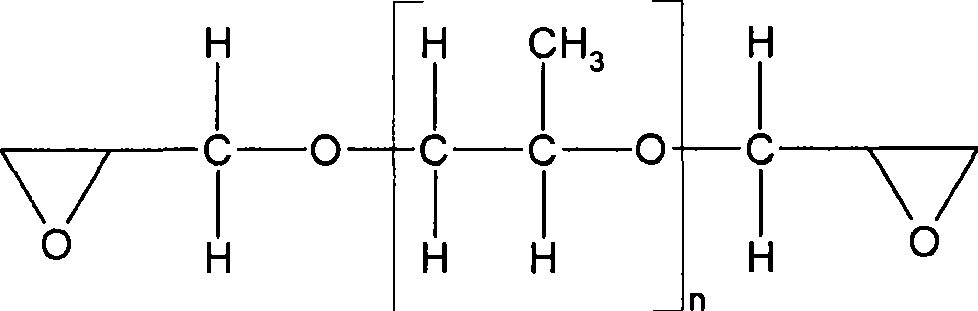

Method used

Image

Examples

Embodiment 1

[0126] The silicone emulsion of the present invention ("emulsion A of the present invention") was prepared by a method comprising the following steps, wherein the amounts of each component were listed in Table 1.

[0127] 1. Add Component I and Component IV-1 to a reaction vessel and mix for 10 minutes under stirring at a speed of 500 rpm.

[0128] 2. With stirring at a speed of 500 rpm, add Component III, Component V-1, Component V-2, glacial acetic acid and 14.6 grams of water and mix for 15 minutes to form a homogeneous mixture.

[0129] 3. Add 128.6 grams of water and mix with stirring at 500 rpm for 30 minutes.

[0130] 4. After heating to a temperature of 70° C., add an aqueous solution consisting of 4 grams of component II and 12 grams of water, and heat at a temperature of 70° C. for 2 hours while stirring at a speed of 400 rpm.

[0131] 5. To the mixture cooled to room temperature was added an aqueous solution consisting of 0.6 g of acetic acid and 2.5 g of water. A...

Embodiment 2

[0134] With reference to the consumption of each component listed in Table 1, repeat the process of Example 1 to prepare another silicone emulsion of the present invention ("emulsion B of the present invention"), the difference is:

[0135] In step 1, component IV-1 is replaced by component IV-2,

[0136] ·Respectively change the amount of water added in step 2 and step 3 to 30 grams and 123.1 grams.

[0137] Obtain opaque white emulsion, its particle size is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com