Magnesium alloy suitable for compression casting ultrathin wall member and preparation method

A magnesium alloy, ultra-thin-wall technology, applied in the field of magnesium alloys, to achieve the effect of excellent castability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

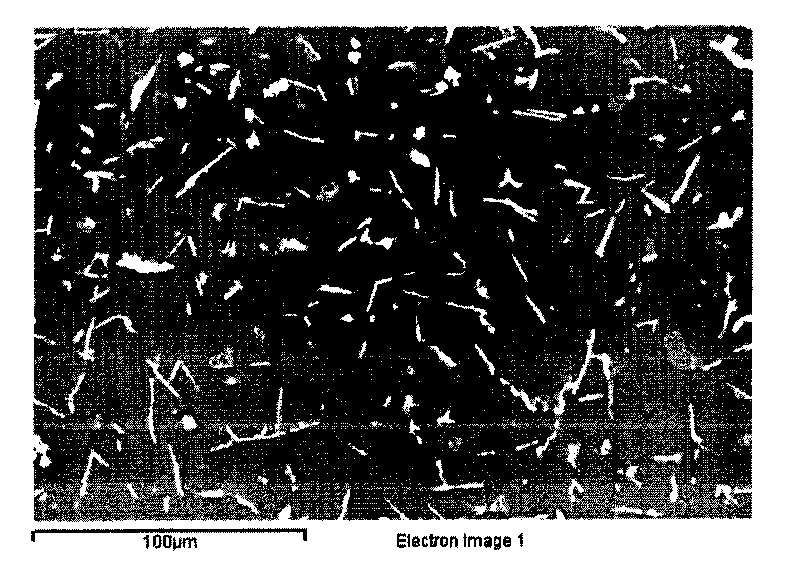

[0036] The proportioning composition (mass percentage) of the alloy is: Al: 13.0%; Nd: 1.0%; Pr: 0.3%; Zn: 0.7%; ≤0.004%, Ni≤0.002%, Fe≤0.004%, and the balance is Mg.

[0037] in CO 2 +SF6 mixed gas (CO 2 : SF 6 =150:1) Under the protection, the magnesium alloy of the above components is smelted in a 10KG magnesium smelting furnace, and the alloy is smelted according to the chemical composition of the alloy. Metal Al (secondary, ≮99%), industrial pure metal, industrial pure metal Zn and a ratio of about: Nd:Pr=5.3:2 industrial grade mixed rare earth alloy or industrial pure Nd and industrial pure Pr, Al in separate form - Mn alloy (Mn about 10%). The melting temperature is about 740°C, and the pouring temperature is about 720°C. The mobile phone shell with a wall thickness of 1mm is die-casted by a magnesium die-casting machine, and the yield rate is 96%. It has also successfully used the crumb-like raw material of the composition alloy to manufacture magnesium alloy not...

Embodiment 2

[0041] The alloy composition (mass percentage) is: Al: 11.3%, Nd: 0.6%, Pr: 0.22%, Zn: 0.5%, Mn: 0.3%, and the unavoidable impurity elements are limited to: Si≤0.05%, Cu≤ 0.004%, Ni≤0.002%, Fe≤0.004%, and the balance is Mg.

[0042] in CO 2 +SF 6 mixed gas (CO 2 :SF 6 =200:1) under the protection, the magnesium alloy of above-mentioned composition is smelted in 10kg magnesium smelting furnace, and alloy is smelted according to alloy chemical composition ratio, and smelting raw material is: industrial pure metal magnesium (grade two,≮99.9%), metal aluminum (Class II, ≮99%), Industrial Pure Zinc (≮99.95%), Industrial Pure Nd-Pr Mixed Rare Earth Alloy (Nd:Pr=5.3:2, RE Total ≮99%, Nd+Pr Total ≮99.9% ), Al-Mn master alloy (Mn is about 10%). The melting temperature is about 740°C, and the pouring temperature is about 720°C. A mobile phone case with a wall thickness of 1 mm is cast by a magnesium die-casting machine, and the yield rate is 95%. It has also successfully used the...

Embodiment 3

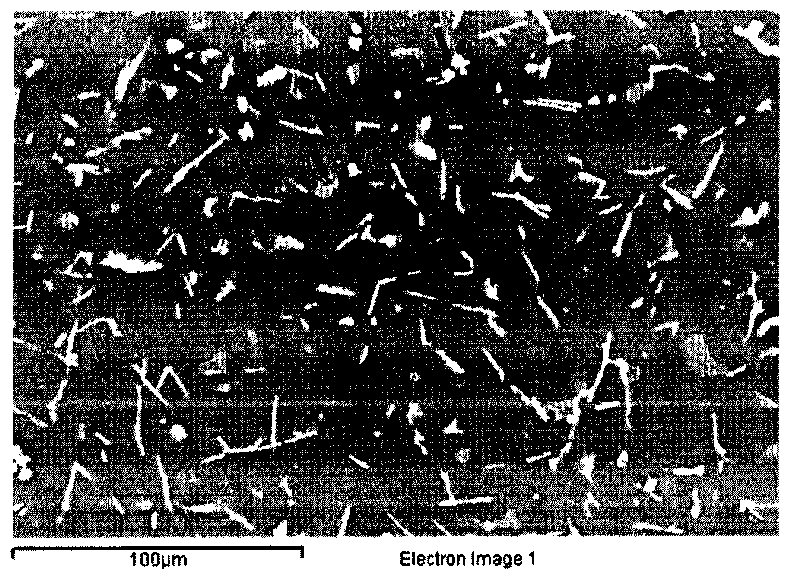

[0044] The alloy composition (mass percentage) is: Al: 13.5%, Nd: 1.8%, Pr: 0.95%, Zn: 0.4%, Mn: 0.3%, and the unavoidable impurity elements are limited to: Si≤0.05%, Cu≤ 0.004%, Ni≤0.002%, Fe≤0.004%, and the balance is Mg.

[0045] in CO 2 +SF 6 mixed gas (CO 2 :SF 6 =180:1) under the protection, the magnesium alloy of above-mentioned composition is smelted in 10kg magnesium smelting furnace, alloy is smelted according to alloy chemical composition ratio, smelting raw material is: industrial pure metal magnesium (secondary, ≮99.9%), metal aluminum (Grade 2, ≮99%), industrial pure metal zinc (≮99.95%), industrial pure Nd-Pr master alloy (Nd:Pr=5.3:2, RE total ≮99.9%, Nd+Pr total ≮99% ), Al-Mn master alloy (Mn is about 10%). The melting temperature is about 740°C, and the pouring temperature is about 720°C. A mobile phone casing with a wall thickness of 1 mm is cast by a magnesium die-casting machine, and the yield rate is 97%. It has also successfully used the shavings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com