Numerical control equipment moving precision test device and test method

A kind of numerical control equipment and motion precision technology, applied in the direction of digital control, electrical testing/monitoring, electrical program control, etc., can solve the problems of fully reflecting the performance index of the measured object, weak advanced, complicated operation, etc., to achieve convenient segmentation test Contrast, easy operation, diverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

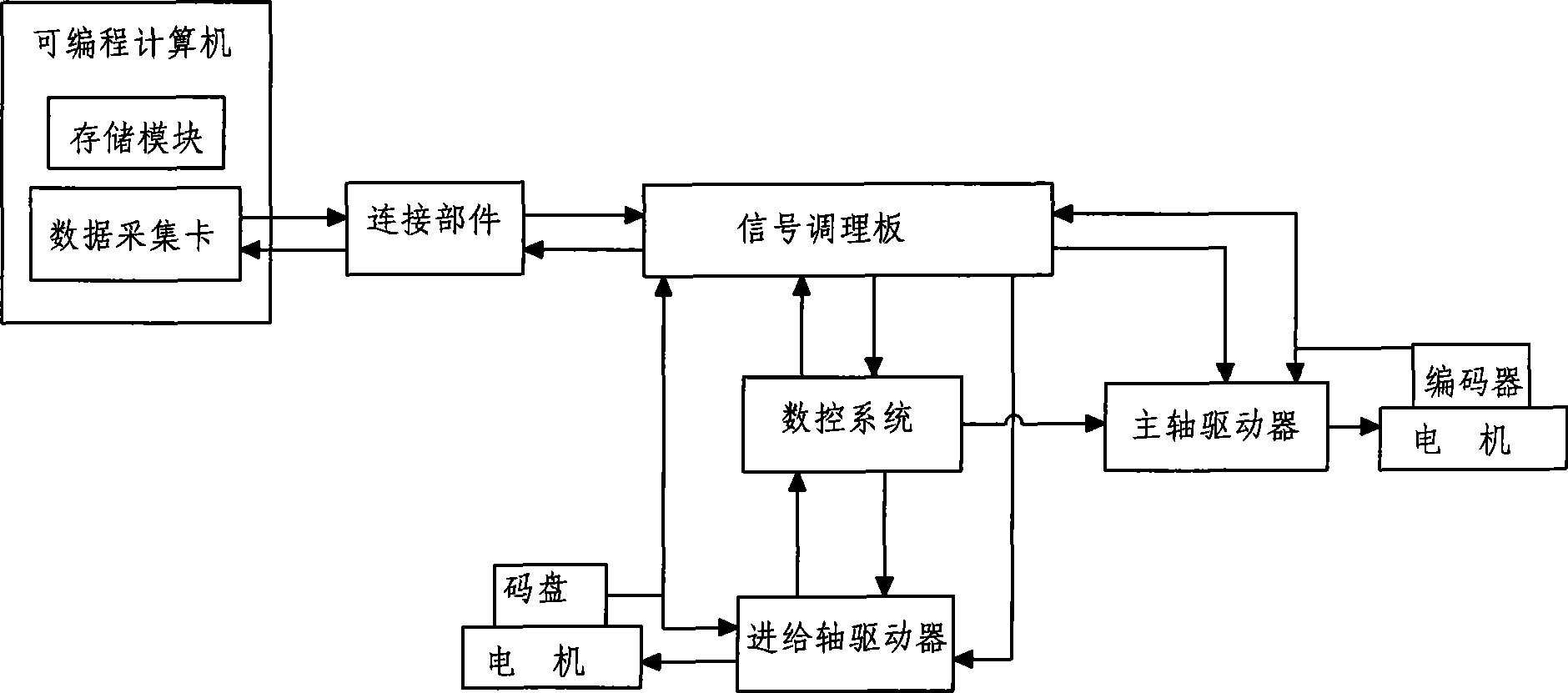

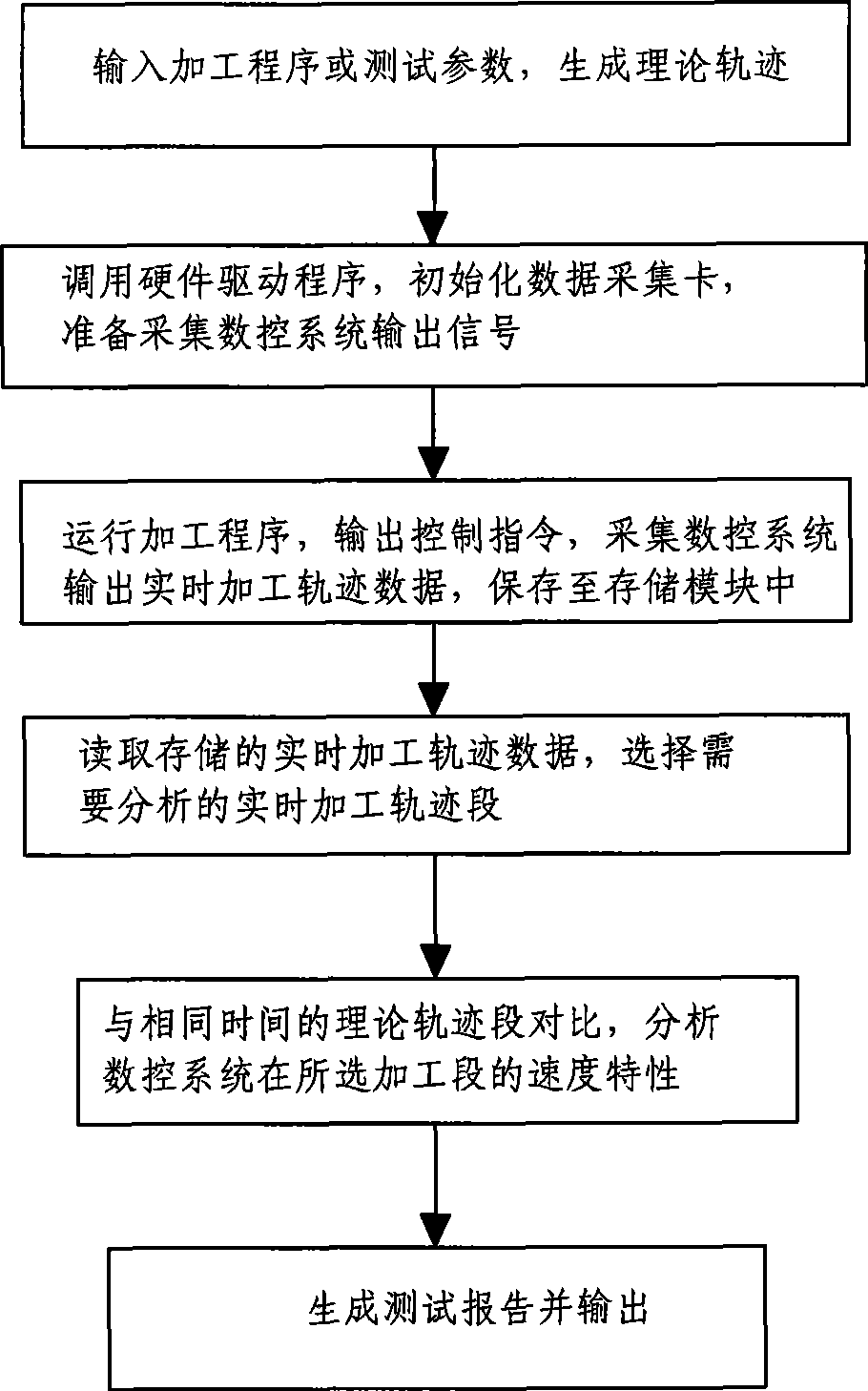

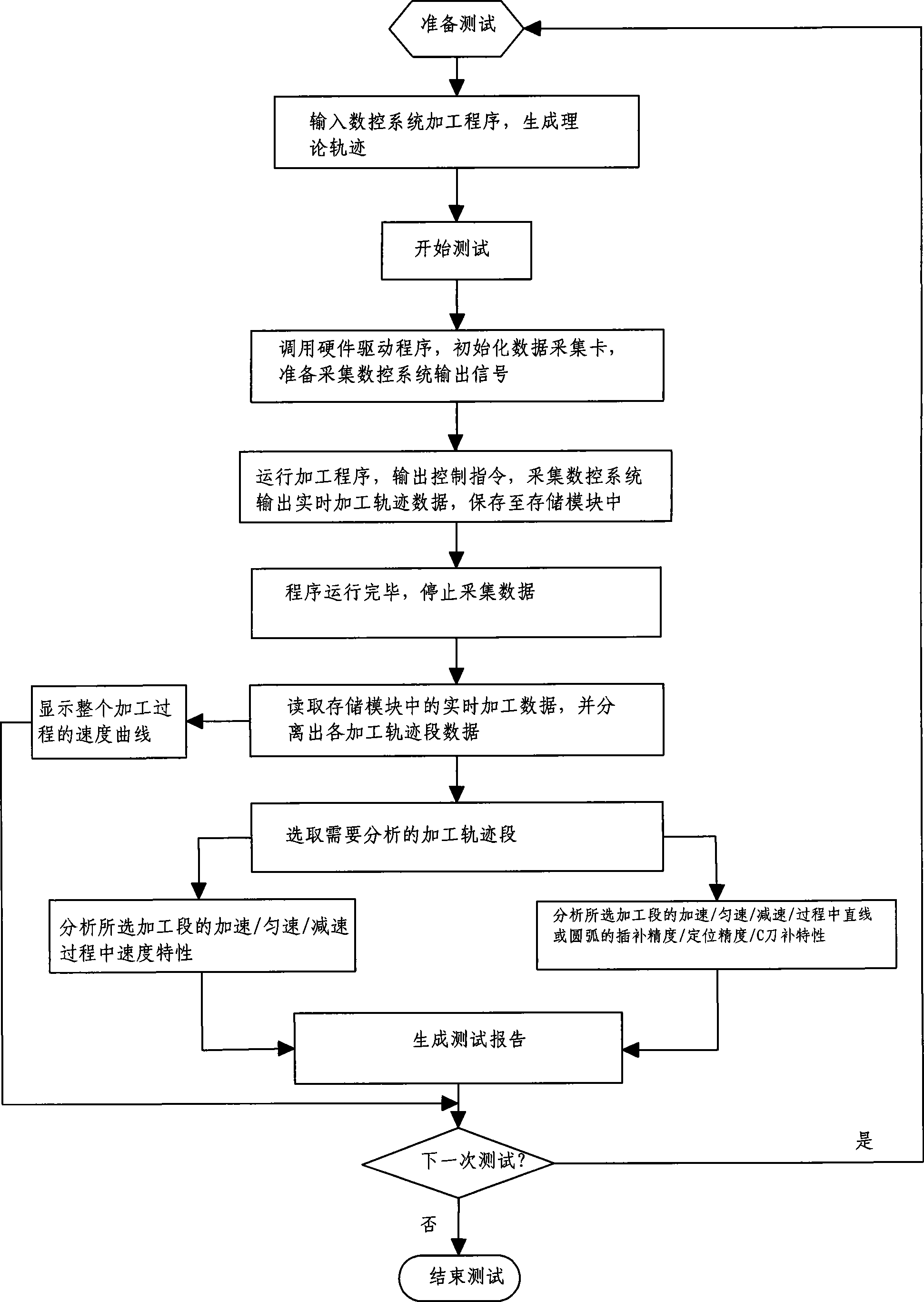

[0039] refer to figure 1 and figure 2 A device for testing motion accuracy of numerical control equipment, the numerical control equipment includes a numerical control system and a driver, and it also includes:

[0040] Connected to the signal conditioning board of the numerical control equipment, it can receive the speed or position pulse signal output by the numerical control system and each drive encoder or code disc in real time, and perform level conversion or input and output mode conversion;

[0041] The data acquisition card can receive the signal input by the signal conditioning board in real time and convert it into a computer-readable signal, and output the control signal to the numerical control system and the driver at the same time;

[0042] Programmable computer with storage module, save preset CNC system processing program and establish theoretical trajectory; can run processing program, output control signal, read real-time processing trajectory data input b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com