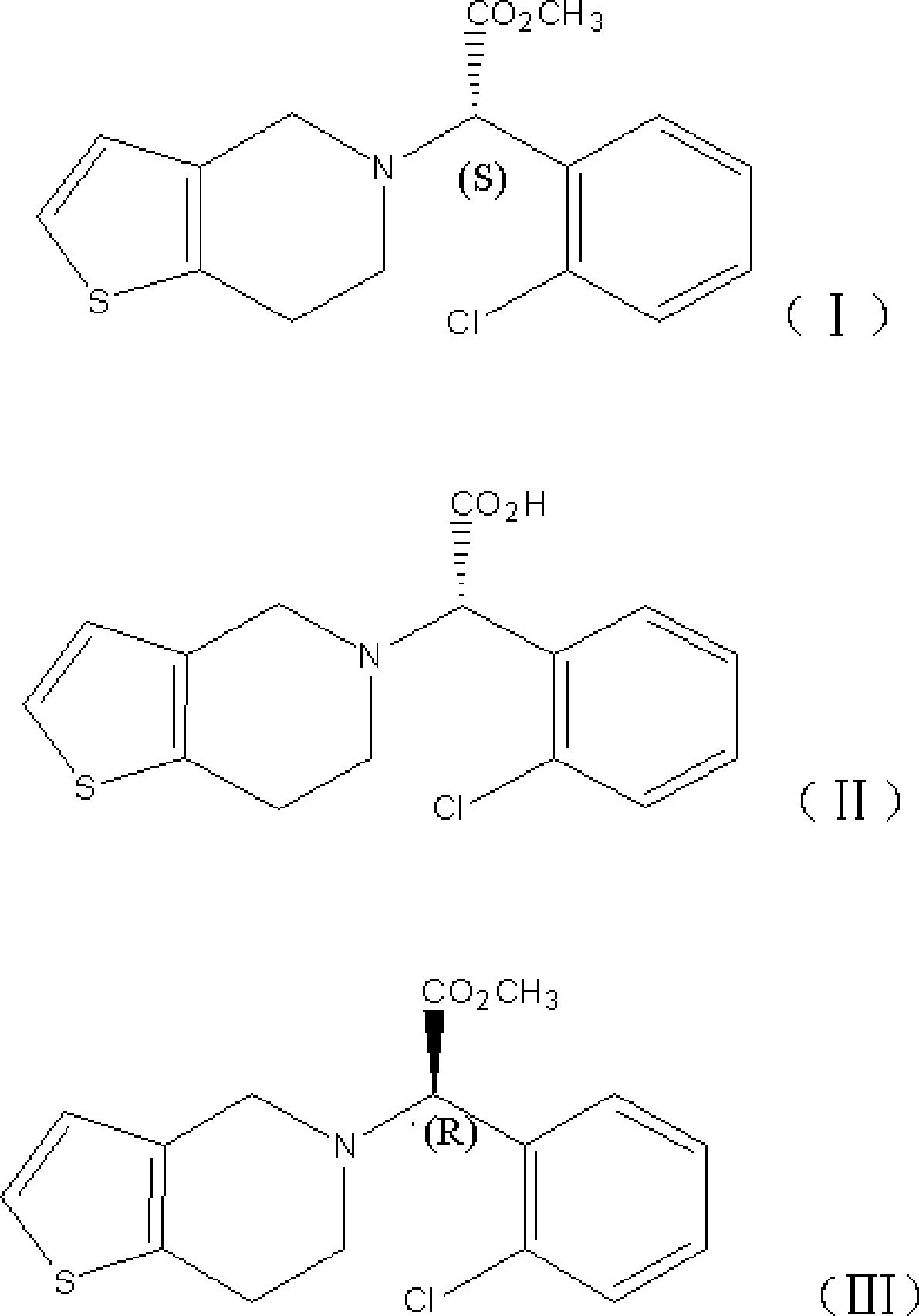

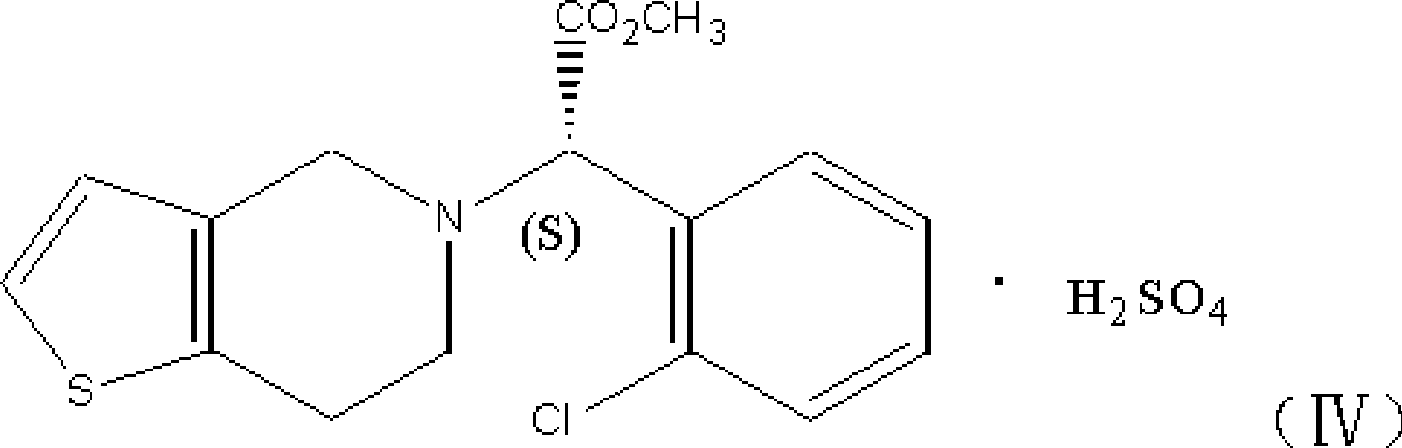

Solid preparation of clopidogrel and preparation method thereof

A clopidogrel, solid preparation technology, applied in the field of medicine, can solve the problem of no anti-platelet aggregation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

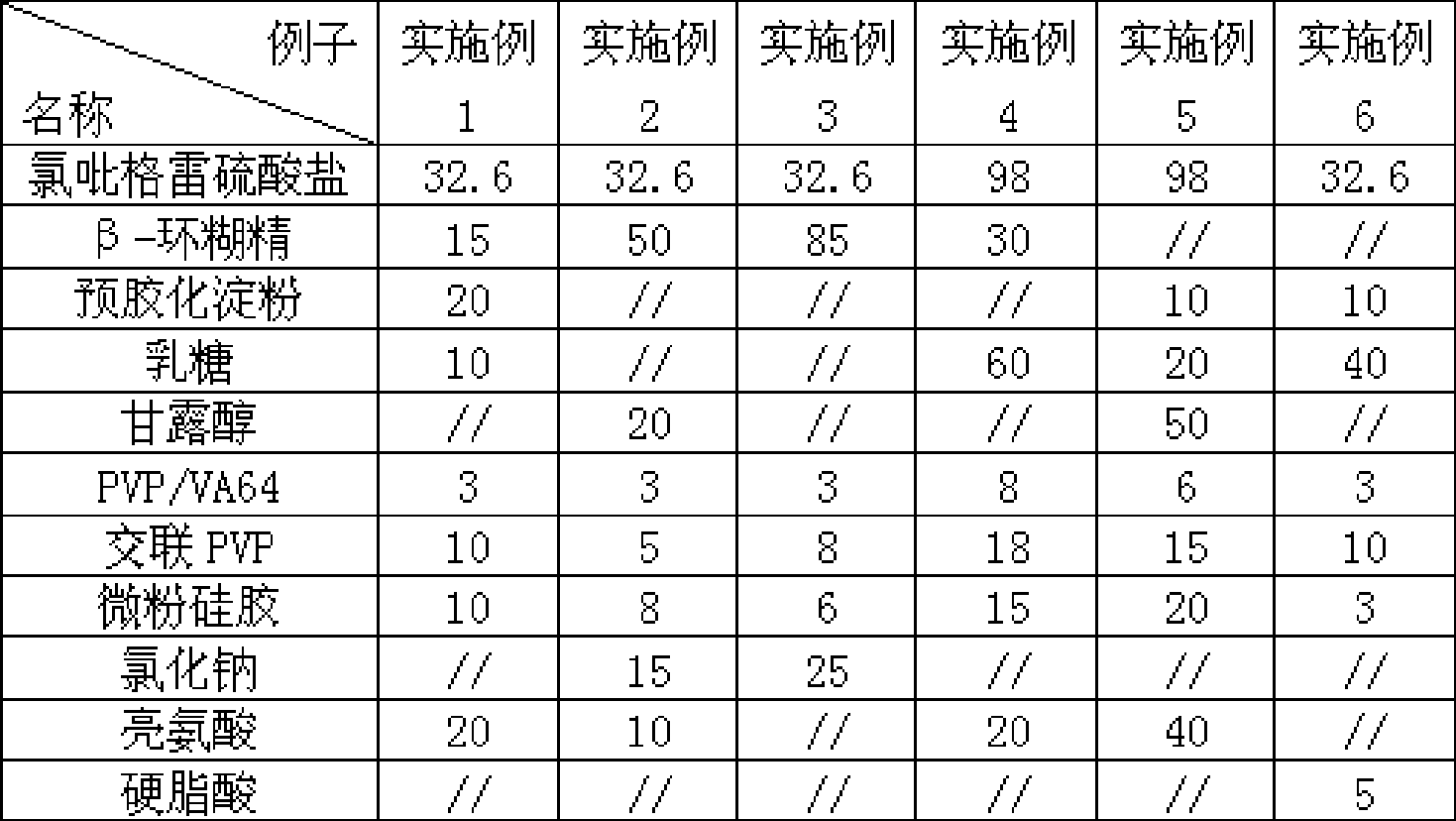

Examples

Embodiment 1

[0039] The preparation method of embodiment 1:

[0040] 1) Crush clopidogrel sulfate and β-cyclodextrin and sieve through a 120-mesh sieve, then mix it with pregelatinized starch, micropowder silica gel and anhydrous lactose, and press it into tablets. After crushing the obtained tablet, pass through a 30-mesh sieve to granulate;

[0041] 2) Mix the granules obtained in operation 1) with polyvinylpyrrolidone copolymer VA64, cross-linked polyvinylpyrrolidone and leucine evenly, and then directly compress to obtain tablets or fill capsule shells or directly seal them into aluminum-plastic composite film bags;

[0042] 3) The obtained plain tablet is coated with a film coating with Opadry II coating powder, the coating temperature is 50° C., and the weight gain after coating is 2.3%.

Embodiment 2

[0043] The preparation method of embodiment 2:

[0044] 1) Mix clopidogrel sulfate and β-cyclodextrin through a 100-mesh sieve, polyvinylpyrrolidone copolymer VA64, micropowder silica gel, cross-linked polyvinylpyrrolidone, sodium chloride and leucine, and then press directly Get tablets or fill capsule shells or directly seal them in aluminum-plastic composite film bags;

[0045] 2) The obtained plain tablet is coated with a film coating with Opadry II coating powder, and the weight gain is controlled to 2.5% after coating.

Embodiment 3

[0046] The preparation method of embodiment 3:

[0047] 1) After crushing clopidogrel sulfate and β-cyclodextrin through a 100-mesh sieve, mix it evenly with polyvinylpyrrolidone copolymer VA64, micropowder silica gel, cross-linked polyvinylpyrrolidone, and sodium chloride, and then directly compress to obtain tablets or Filling capsule shells or directly sealing them into aluminum-plastic composite film bags;

[0048] 2) The obtained plain tablet is coated with a film coating with Opadry II coating powder, and the weight gain is controlled to 2.5% after coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com