Solid state polymerization technique of polyester industry

A solid-phase polymerization and process technology, which is applied in the field of solid-phase polymerization technology, can solve the problems of inability to further expand the dust removal capacity, unstable product quality, poor production stability, etc. block effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

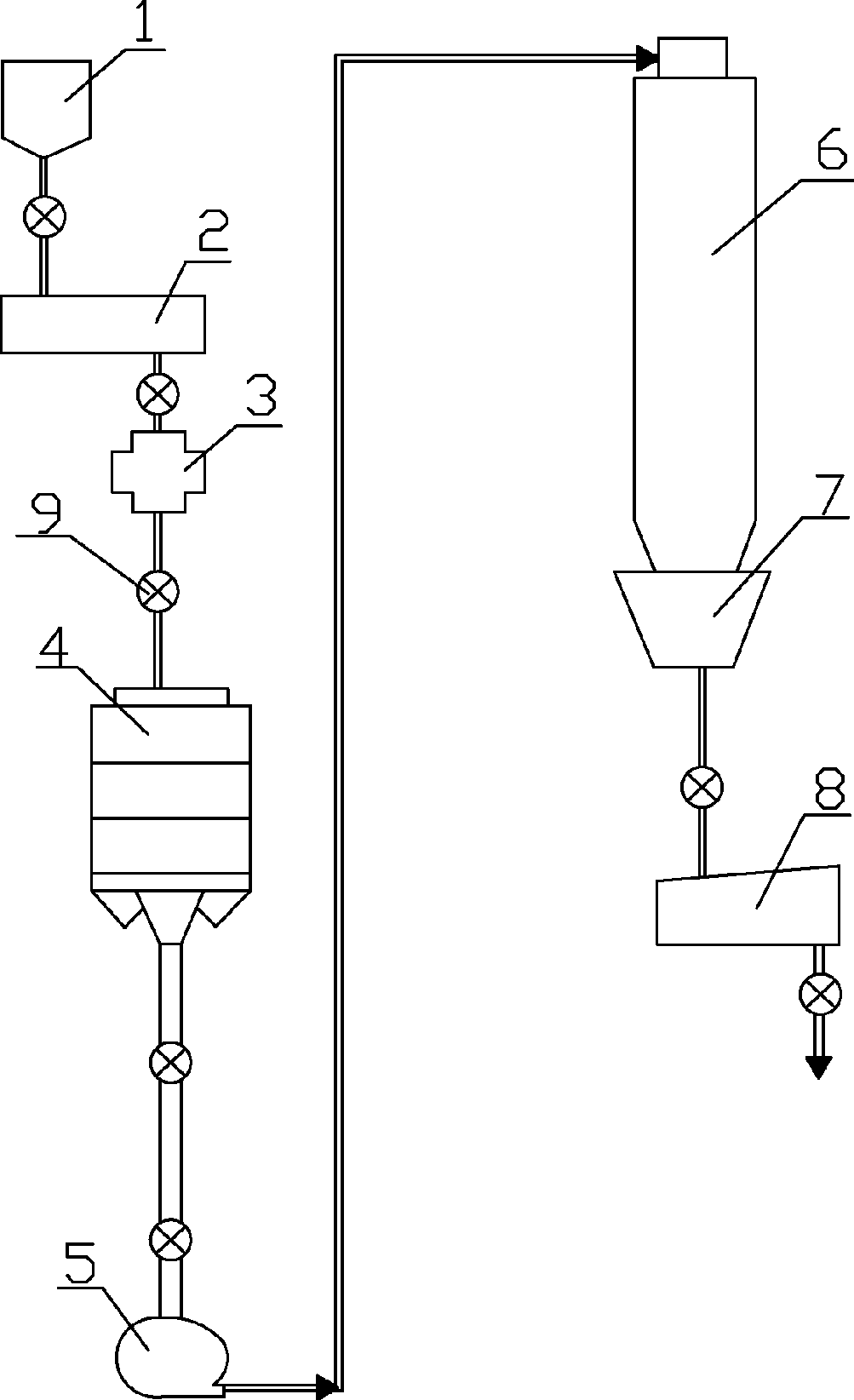

[0015] Embodiments of the present invention: the process route of the present invention is as follows: raw material (low-viscosity slice)—pre-crystallization—on-line dedusting—recrystallization / preheating—hot state conveying—main reaction—mechanical discharge—cooling and dust removal—finished product (high viscosity slice), its specific reaction process is as follows:

[0016] The low-viscosity chips used as raw materials arrive at the pre-crystallizer 2 from the raw material storage tank 1 through the rotary valve 9. The pre-crystallizer 2 is a Sulida horizontal stirring paddle crystallizer. The Sulida crystallizer is a screw shaft propulsion crystallizer produced in the United States. The paddle can drive the material to move in a circular motion, and push the slices to the container wall to absorb heat, so that the material can obtain heat during the movement to fully dry and crystallize. It is heated by jacketed hot oil, and the temperature of the heated oil is 225-250 °C. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com