All bio-decomposable starch-resin, preparation method thereof, film products and resin composition for preparing starch-resin

A biodegradable, starch resin technology, applied in the field of biodegradable starch resin, can solve the problems of insufficient toughness, environmental pollution, insufficient application of blown film, etc., and achieve the effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The total weight of the resin composition was 100 kg, which contained 44.8% by weight of tapioca starch, 38.8% by weight of PBAT ester grains, 11.9% by weight of glycerin, 4% by weight of water, 0.5% by weight of lecithin, and 0.5% by weight of starch hydrolysis enzyme solution.

[0044] Firstly put the tapioca starch in the first waiting barrel, put the PBAT ester grains in the second waiting barrel, and put the liquid raw materials such as glycerin, water, lecithin and starch hydrolytic enzyme in the third waiting barrel and then put the cassava starch in the first bucket for feeding into the mixing bucket, then add the PBAT ester grains in the second bucket for feeding into the mixing bucket, then put the liquid starch in the third bucket for feeding The raw materials are evenly sprayed into the mixing barrel, and all the raw materials are mixed evenly and then sent to the feeding barrel of the twin-screw extruder, and then mixed by the twin-screw extruder to obtain a...

Embodiment 2~8

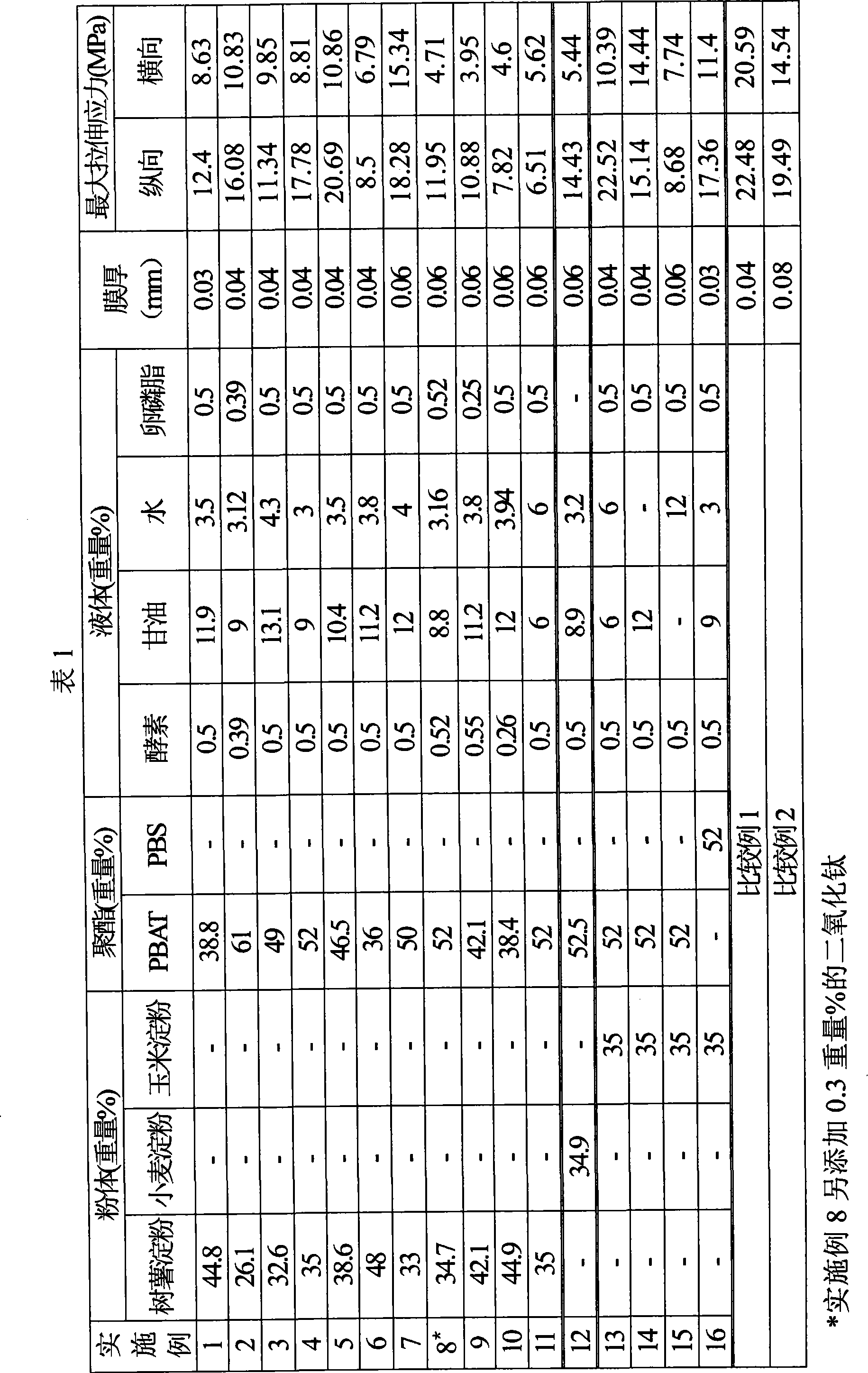

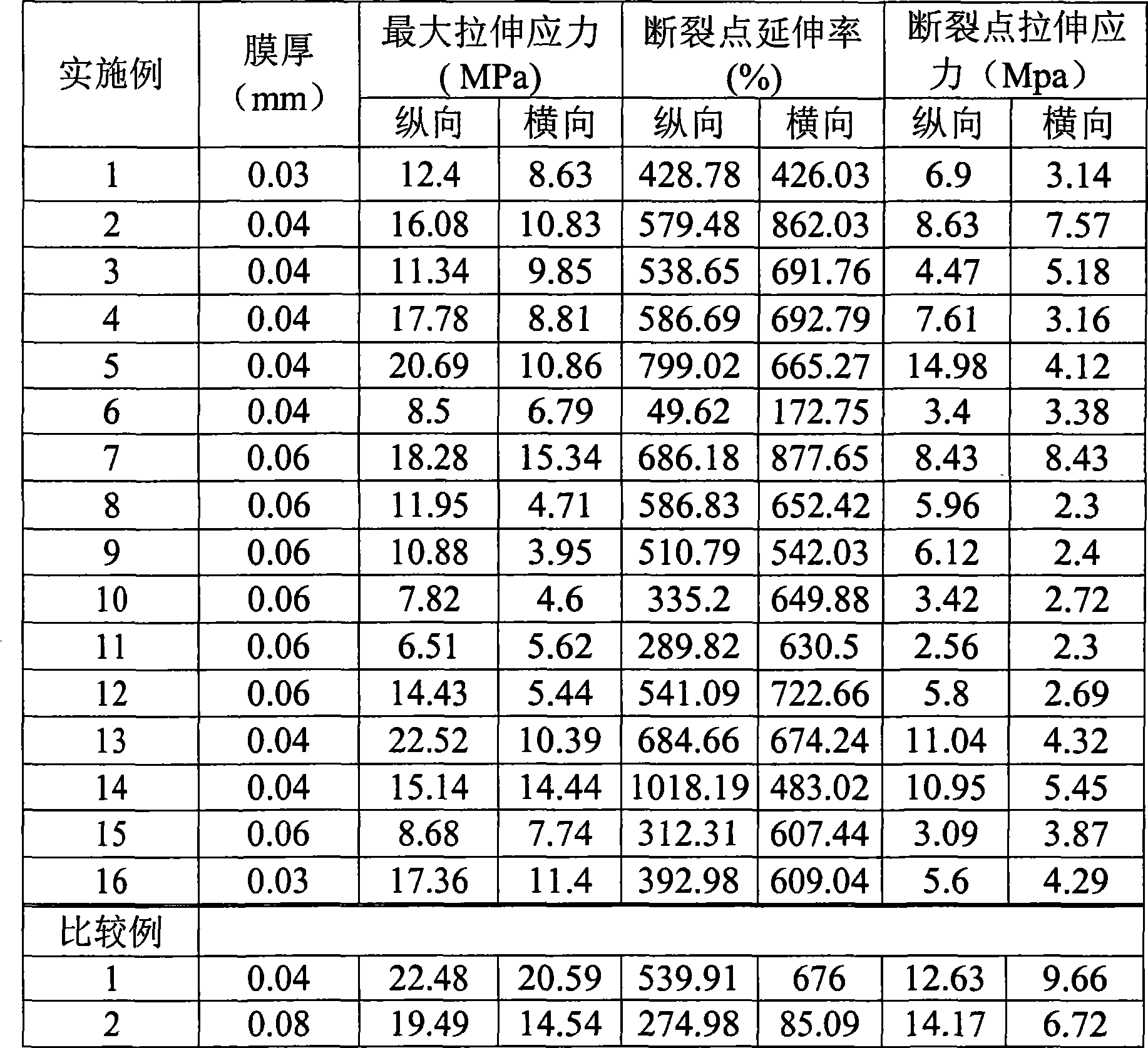

[0046] The implementation procedure of Examples 2-8 is the same as that of Example 1, except that the component ratios of the resin compositions of Examples 2-8 are shown in Table 1 below.

Embodiment 9~16

[0048] The implementation steps of Examples 9 to 16 are except that the screw speed of the twin-screw extruder is set at 250rpm, and the temperature settings of the eleven zones from the feed end to the extrusion end of the screw are sequentially set at 30°C, 110°C, and 120°C. °C, 125 °C, 125 °C, 125 °C, 130 °C, 135 °C, 135 °C, 125 °C, and 90 °C, the rest are approximately the same as in Example 1. In addition, the component ratios of the resin compositions of Examples 9-16 are shown in Table 1 below, wherein Example 8 additionally added 0.3% by weight of titanium dioxide, and the titanium dioxide was first placed in the first waiting tank and mixed with tapioca starch.

[0049] blown film

[0050] Get respectively about 10 kilograms of resin pellets of the starch resins obtained in the aforementioned embodiments 1 to 16, and utilize an extrusion type blown film machine (Blown Film Extruder) to make films of different thicknesses. The films made by the resin pellets of each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com