Method of water treatment in steam plant

A water treatment and steam technology, applied in natural water treatment, water treatment parameter control, neutralized water/sewage treatment, etc., can solve the problems of easy to produce scale, difficult to use atomic energy facilities, expensive hydrazine, etc., to prevent scale. attached effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

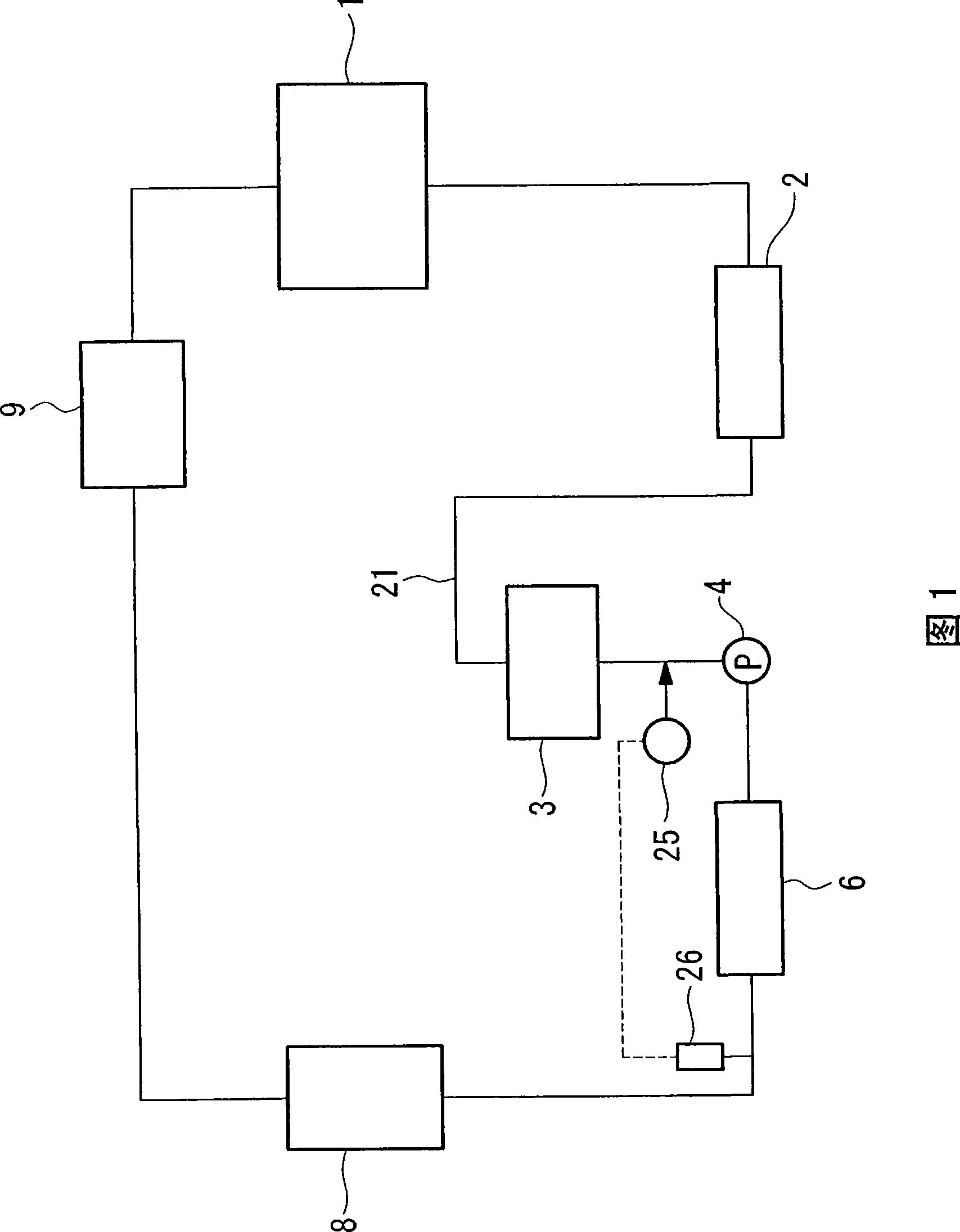

[0037] Hereinafter, the water treatment method of the steam facility according to the first embodiment of the present invention will be described based on FIGS. 1 and 2 .

[0038] FIG. 1 is a flowchart showing an example of a steam facility to be treated by a water treatment method according to a first embodiment.

[0039] In the water treatment method of the steam facility of the first embodiment, the steam facility includes: a boiler 8, which generates water vapor by heat from a heat source; a steam turbine 9, which operates by steam from the turbine 8; a condenser 1, It condenses the water vapor discharged from the steam turbine 9 into condensed water; a water supply pump (water supply device) 4, which sends the condensed water condensed by the condenser 1 to the boiler 8; a flow path 21, which is connected to all The boiler 8, the steam turbine 9, the condenser 1 and the water supply pump 4 are circulated. In addition, in this steam facility, a low-pressure heater 2 and a...

no. 2 approach

[0056] Hereinafter, a water treatment method of a steam facility according to a second embodiment of the present invention will be described. In addition, since the structure of the steam facility to be the object of the water treatment method of the present embodiment is the same as that of the steam facility to be the object of the water treatment method of the first embodiment shown in FIG. 1 , this embodiment will also be described with reference to FIG. 1 , and omit the description of common structural elements.

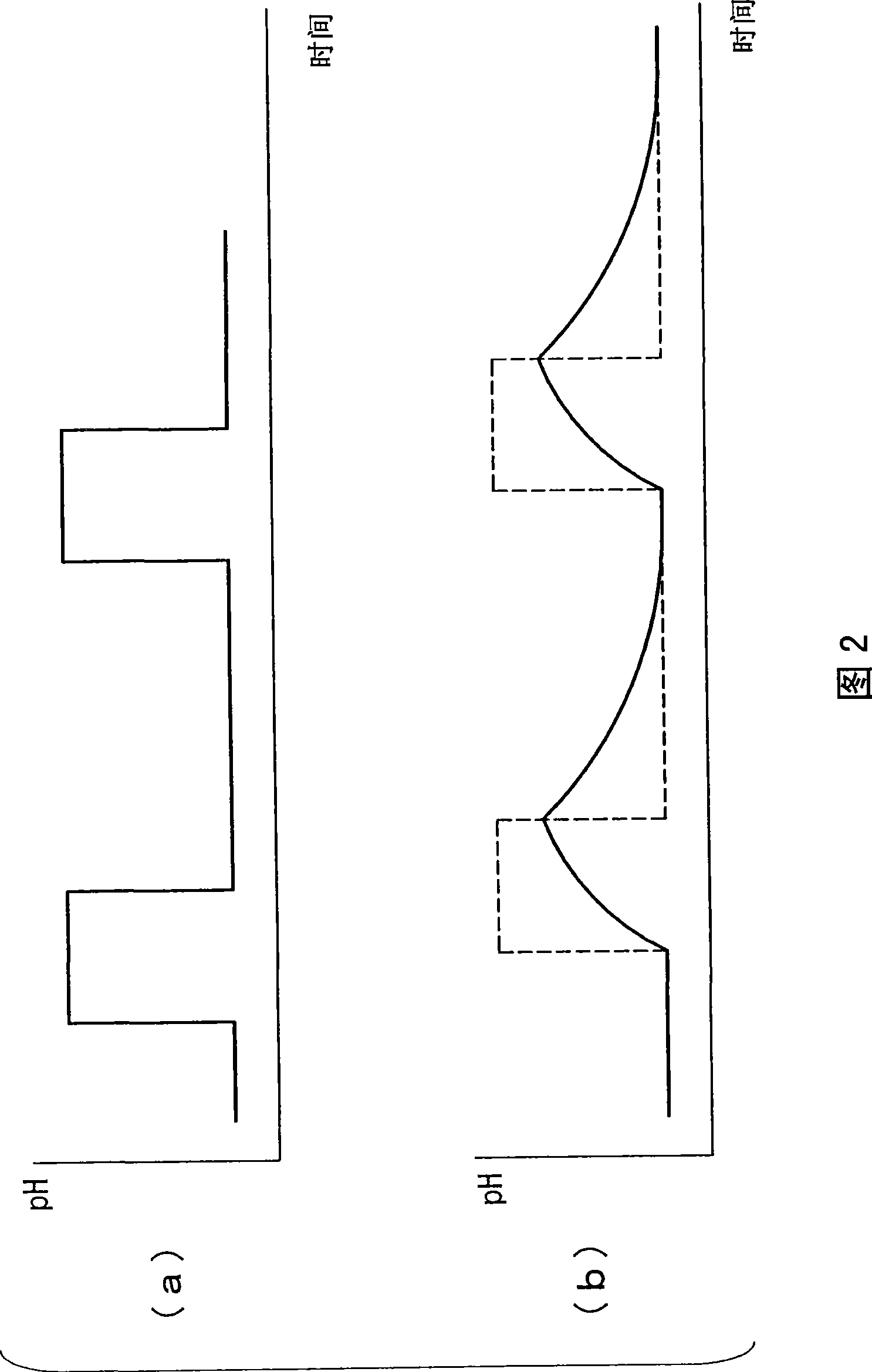

[0057] In the water treatment method of a steam facility according to the present embodiment, during operation of the steam facility, substantially periodic chemical environmental fluctuations are given to the flow paths in predetermined equipment provided on the flow paths 21 .

[0058] In the present embodiment, the above-mentioned "predetermined equipment" refers to equipment in which scale adhesion becomes a problem in the steam facility, similarly to the fi...

no. 3 approach

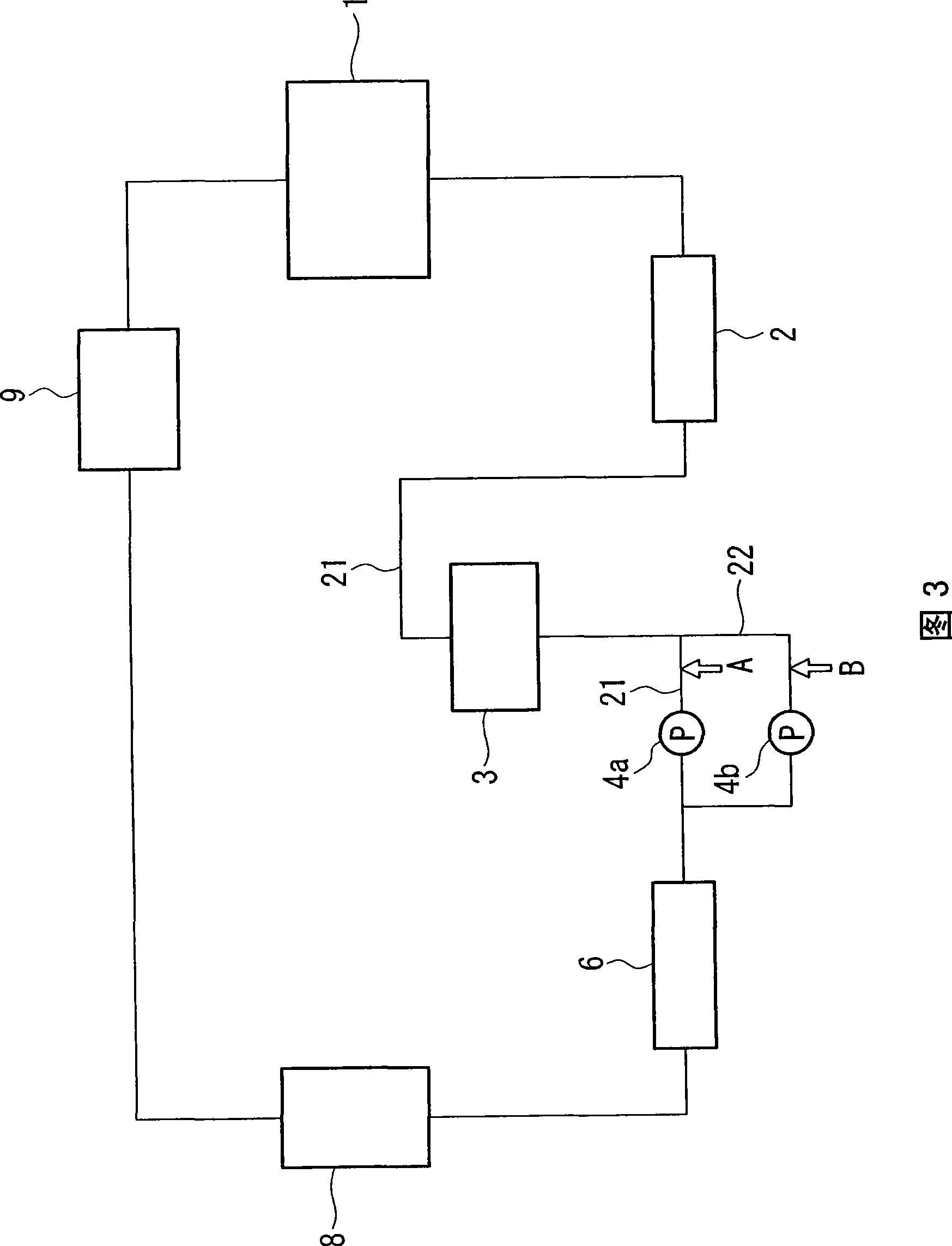

[0071] Hereinafter, a water treatment method of a steam facility according to a third embodiment of the present invention will be described based on FIG. 3 .

[0072] 3 is a flowchart showing an example of a steam facility to be treated by a water treatment method according to a third embodiment.

[0073]In addition, in the structure of the steam facility to be the object of the water treatment method of this embodiment, except that a plurality of water supply pumps (the first water supply pump 4a and the second water supply pump 4b) are arranged in parallel, the other is the same as that shown in FIG. 1 . Since the steam facilities targeted by the water treatment methods of the first embodiment and the second embodiment are the same, descriptions of common structural elements are omitted.

[0074] In addition, since the types of medicines used in this embodiment are also the same as those in the first and second embodiments, description thereof will be omitted.

[0075] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com