Method for synthesizing SAPO-35 molecular sieve

A technique for the synthesis of SAPO-35, which is applied in the direction of molecular sieves, alkali-exchanged phosphates, molecular sieve characteristic silicoaluminophosphates, etc., to achieve the effects of high product yield, high specific surface area, good thermal stability and hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example illustrates the synthesis method of the SAPO-35 molecular sieve provided by the present invention.

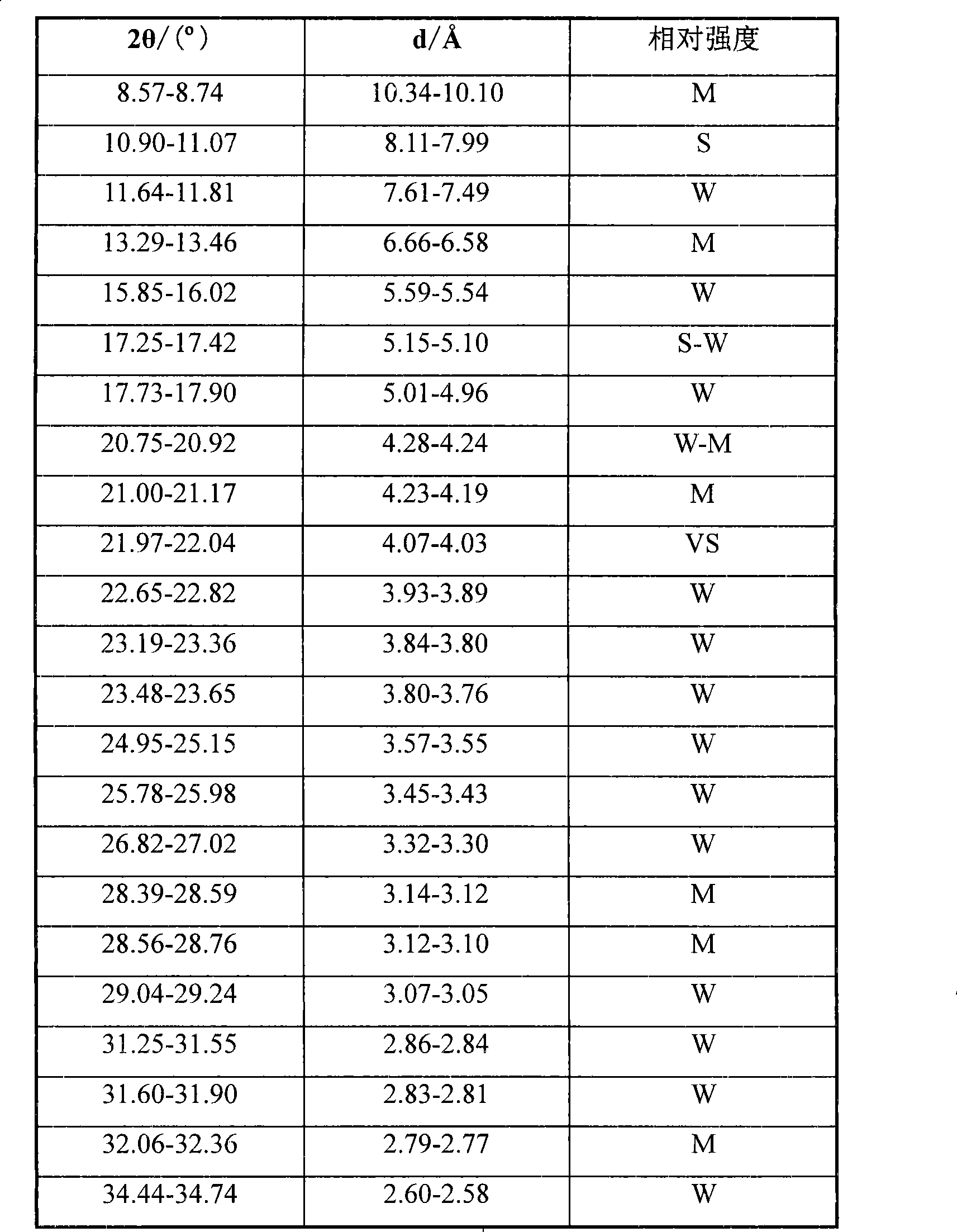

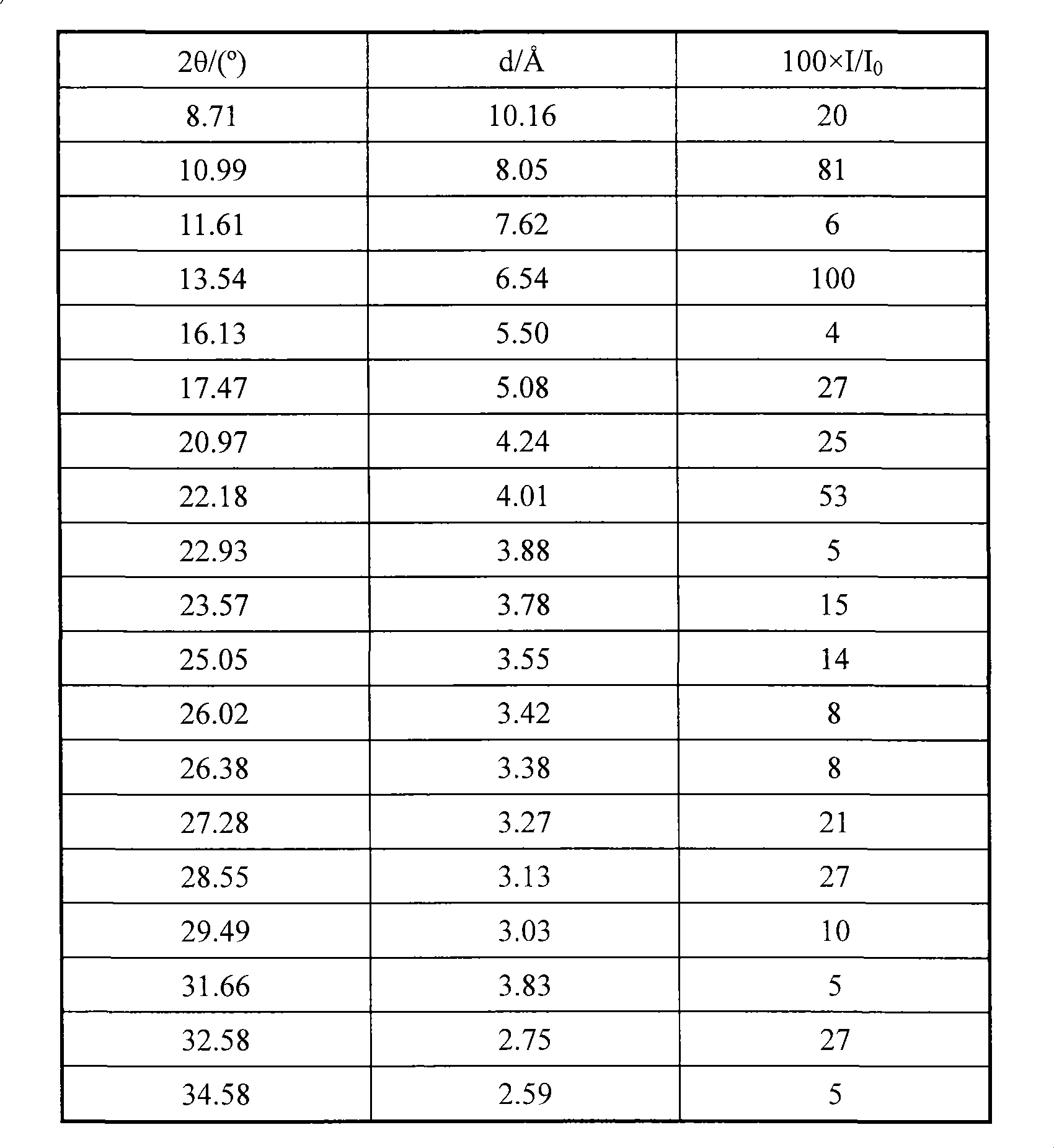

[0028] 155g phosphoric acid (containing H 3 PO 4 85w%, industrial product) and 619.9g of deionized water are added to the gelling kettle placed in a water bath of 60°C and mixed and stirred evenly. After stirring for 10 minutes, 102g of hydrated aluminum oxide (containing Al 2 o 3 70w%), continue stirring for no less than 1 hour, then add 33.6g silica sol (containing SiO 2 25w%) and stirred for 0.5 hour, then added 105.2g of hexamethyleneimine (chemically pure) into the above-mentioned gelling kettle and mixed evenly to prepare a reaction mixture. Part of the above-mentioned mixed material was transferred into a stainless steel crystallization kettle and sealed, and stirred and crystallized at 200° C. and autogenous pressure for 24 hours. The crystallized product is then filtered, washed, and dried at 100-110°C to obtain the molecular sieve raw powder pr...

Embodiment 2

[0034] This example illustrates the synthesis method of the SAPO-35 molecular sieve provided by the present invention.

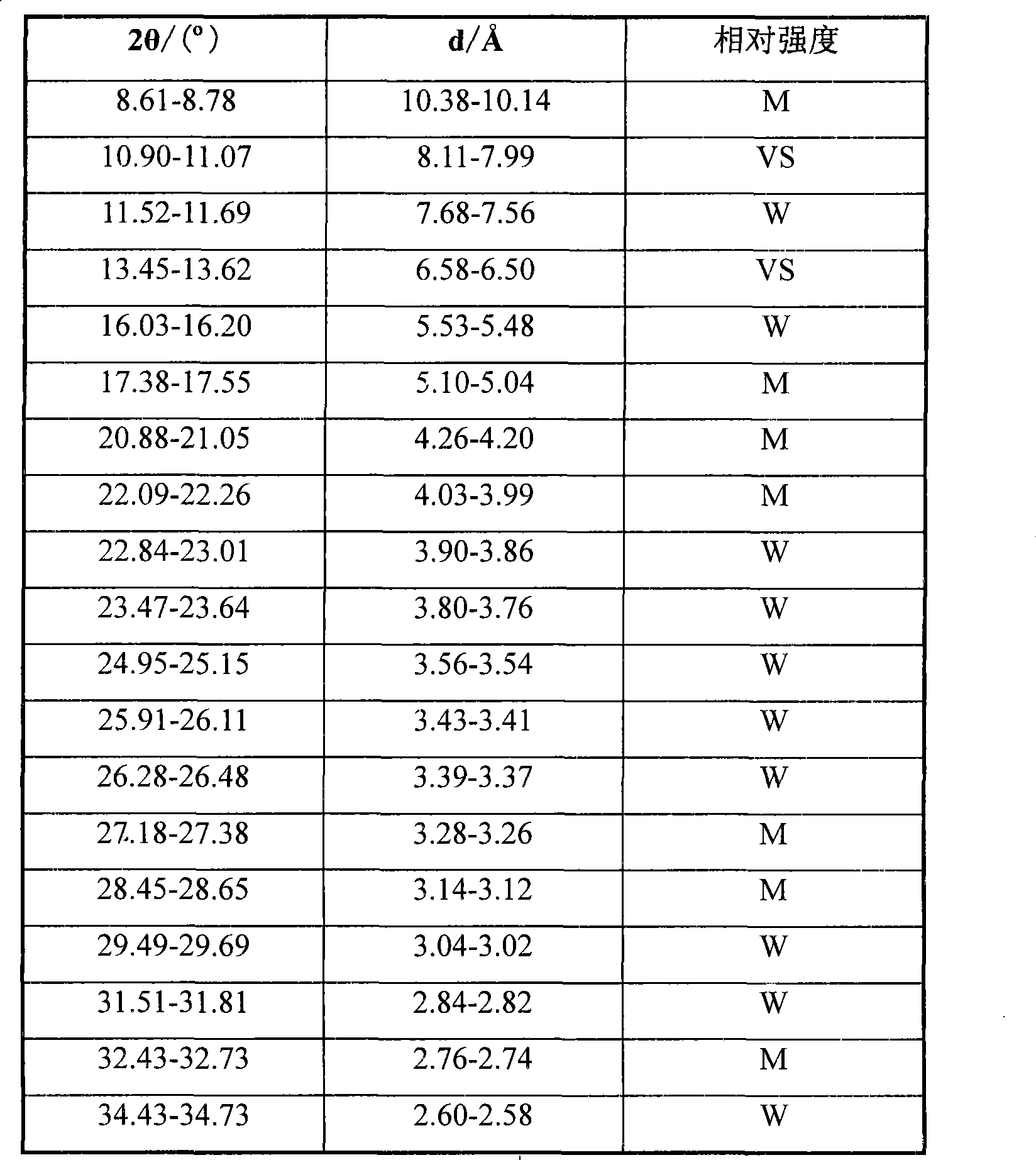

[0035] In Example 1, 33.6g of silica sol was changed into 50.5g of silica sol, 619.9g of deionized water was changed into 607.8g of deionized water, and gel was mixed in a gelling kettle placed in a water bath at 70°C. The separation and synthesis conditions were unchanged, and the molecular sieve raw powder product A2 was obtained, and the XRD analysis results of A2 were consistent with the data in Table 1, indicating that it was a SAPO-35 molecular sieve. The X-ray powder diffraction measurement result of the molecular sieve after roasting removes template agent accords with the data in table 2, and the element chemical composition of this molecular sieve is Al 2 o 3 :P 2 o 5 :SiO2 2 =1:0.77:0.31, the specific surface area after calcining to remove the template is 493m 2 / g, the pore volume is 0.254ml / g.

Embodiment 3

[0039] This example illustrates the synthesis method of the SAPO-35 molecular sieve provided by the present invention.

[0040] Change 33.6g of silica sol in Example 1 to 134.6g of silica sol, 619.9g of deionized water to 544.2g of deionized water, the gelling temperature is 50°C, and the remaining components and synthesis conditions remain unchanged to obtain the molecular sieve raw powder The XRD analysis results of sample A3 and A3 are consistent with the data in Table 1, indicating that it is SAPO-35 molecular sieve. The X-ray powder diffraction measurement results of the molecular sieve after the template agent was removed by calcination accord with the data in Table 2. The elemental chemical composition of the molecular sieve is Al 2 o 3 :P 2 o 5 :SiO2 2 =1:0.79:0.75, the specific surface area after calcining to remove the template is 491m 2 / g, the pore volume is 0.31ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com