Automatic detection method for oblique incidence wave technology steel plate and device thereof

An automatic detection device, oblique incidence technology, applied in measuring devices, using ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, etc., can solve problems such as inability to effectively detect cracks, and achieve high detection accuracy and real-time performance , strong environmental adaptability and high confidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

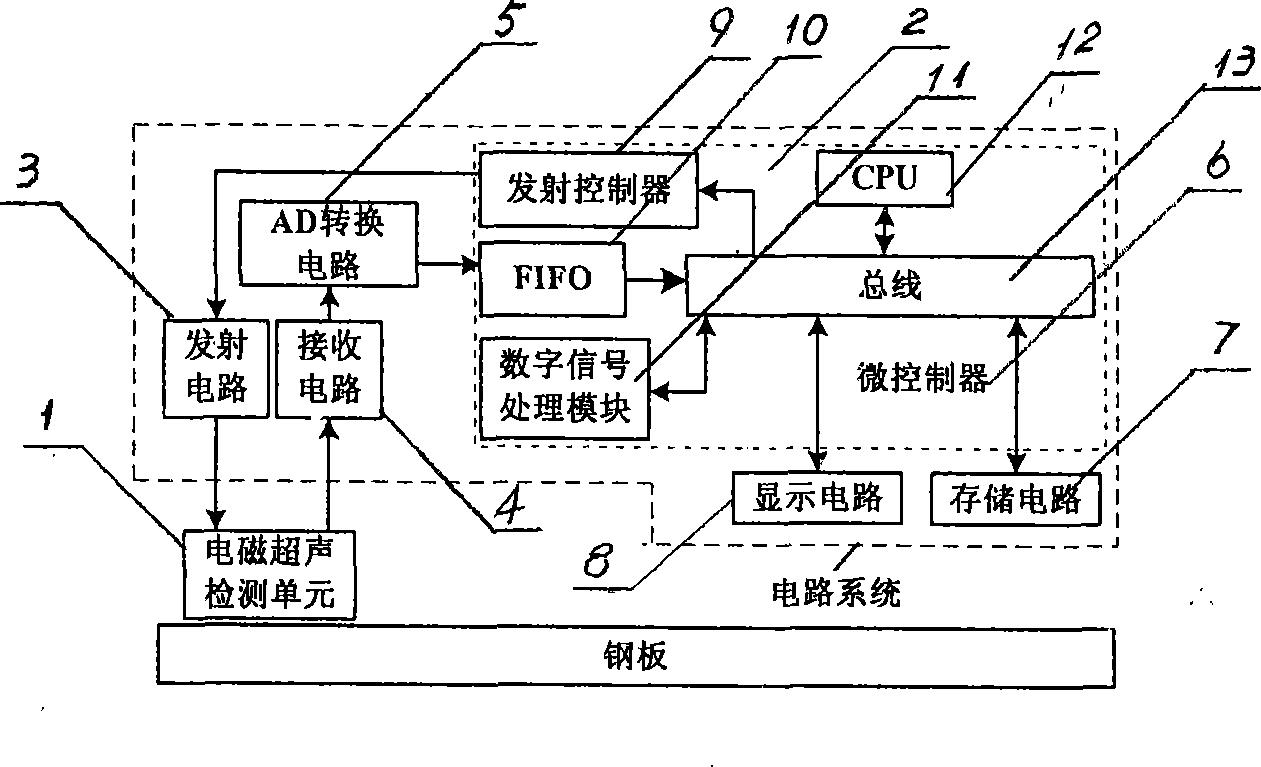

[0039] Embodiment 1, combining figure 1 , the present invention oblique incidence body wave technology steel plate automatic detection device, it is made up of electromagnetic ultrasonic detection unit (1) and circuit system (2); Electromagnetic ultrasonic detection unit (1) connects circuit system (2). Described circuit system (2) comprises transmitting circuit (3), receiving circuit (4), AD conversion circuit (5), microcontroller (6), memory circuit (7) and display circuit (8); Transmitting circuit ( 3) Connect the microcontroller (6), the receiving circuit (4) is connected to the AD conversion circuit (5), the AD conversion circuit (5) is connected to the microcontroller (6), and the microcontroller (6) is connected to the storage circuit (7), The microcontroller (6) is connected to the display circuit (8). Described microcontroller (6) is made up of launch controller (9), FIFO (10), digital signal processing module (11), CPU (12) and bus (13); Launch controller (9) connec...

Embodiment 2

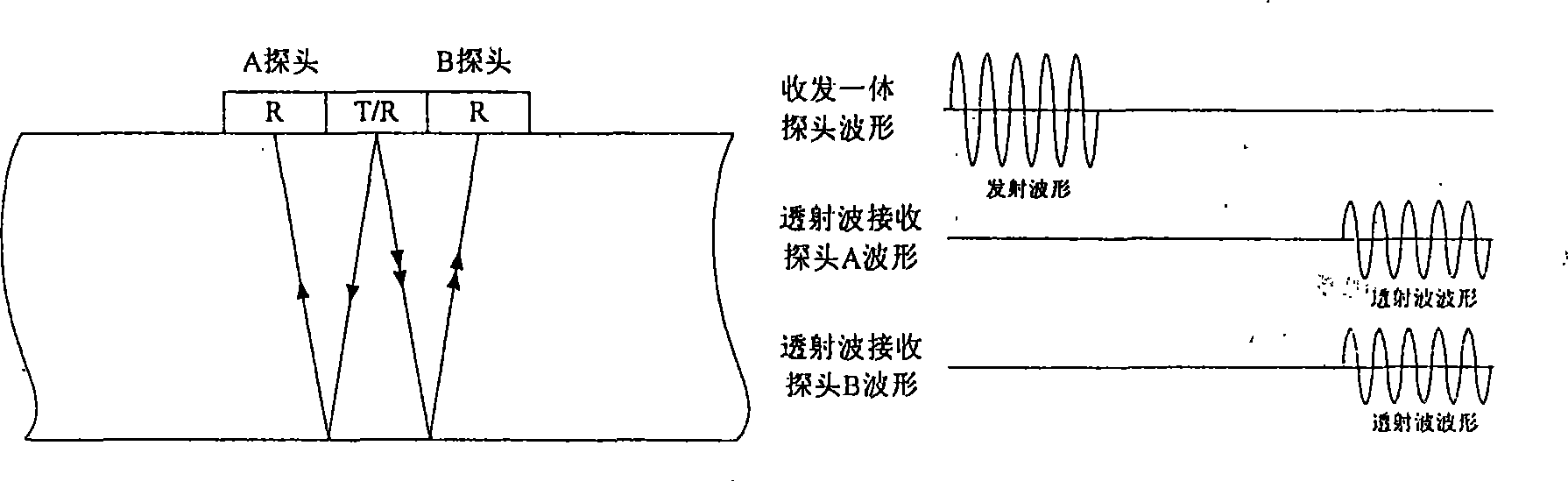

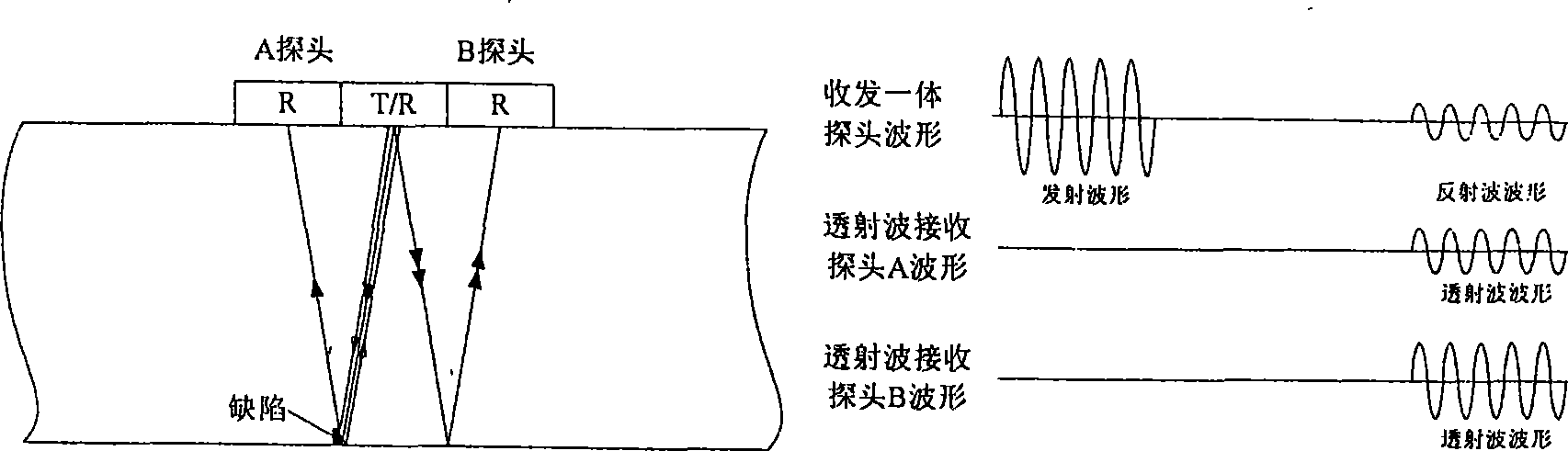

[0040] Example 2, combined with Figure 4 , Figure 5 , the present invention utilizes electromagnetic ultrasonic technology to directly generate body waves incident at a certain angle to the surface of the steel plate in the steel plate to be tested, that is, obliquely incident SV waves (Shear Vertical Wave). Obliquely incident SV waves are sensitive to defects such as delamination, inclusions, hole shapes, and small cracks in the steel plate. In addition, since electromagnetic ultrasonic technology does not require acoustic coupling agents and pretreatment of specimens during detection, the oblique incident body waves generated by it can be used to detect steel plates in various harsh environments online or in service in real time.

[0041] The electromagnetic ultrasonic transverse and longitudinal detection units are composed of three electromagnetic ultrasonic probes, one of which works in the state of transmitting and receiving, and has an electromagnetic ultrasonic tran...

Embodiment 3

[0042] Example 3, combined with Image 6 , Figure 7 , the circuit system periodically stimulates the transceiver integrated probe in the detection unit under the control of the microcontroller to generate obliquely incident SV waves. The SV wave propagating in the steel plate will be reflected and scattered at the defect and the end surface, and the reflected and transmitted ultrasonic signals can be received by the electromagnetic ultrasonic transceiver integrated probe and two transmitted wave receiving probes respectively. The detection device collects and stores the received signal in the detection unit under the control of the microcontroller. The shape and location of the defect can be determined by analyzing the reflected and transmitted signals. The detection results will be displayed in real time under the control of the microcontroller. In order to realize 100% no blind spot detection on the steel plate, the detection unit of the present invention adopts a combin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com