Power generation control device

一种发电控制、发电机的技术,应用在电路装置、发电机控制零部件、电池电路装置等方向,能够解决无法大幅地改善引擎平滑性、引擎旋转缺乏平滑性、很难减轻转矩变动等问题,达到旋转稳定、抑制负荷的增大、吸气效率稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

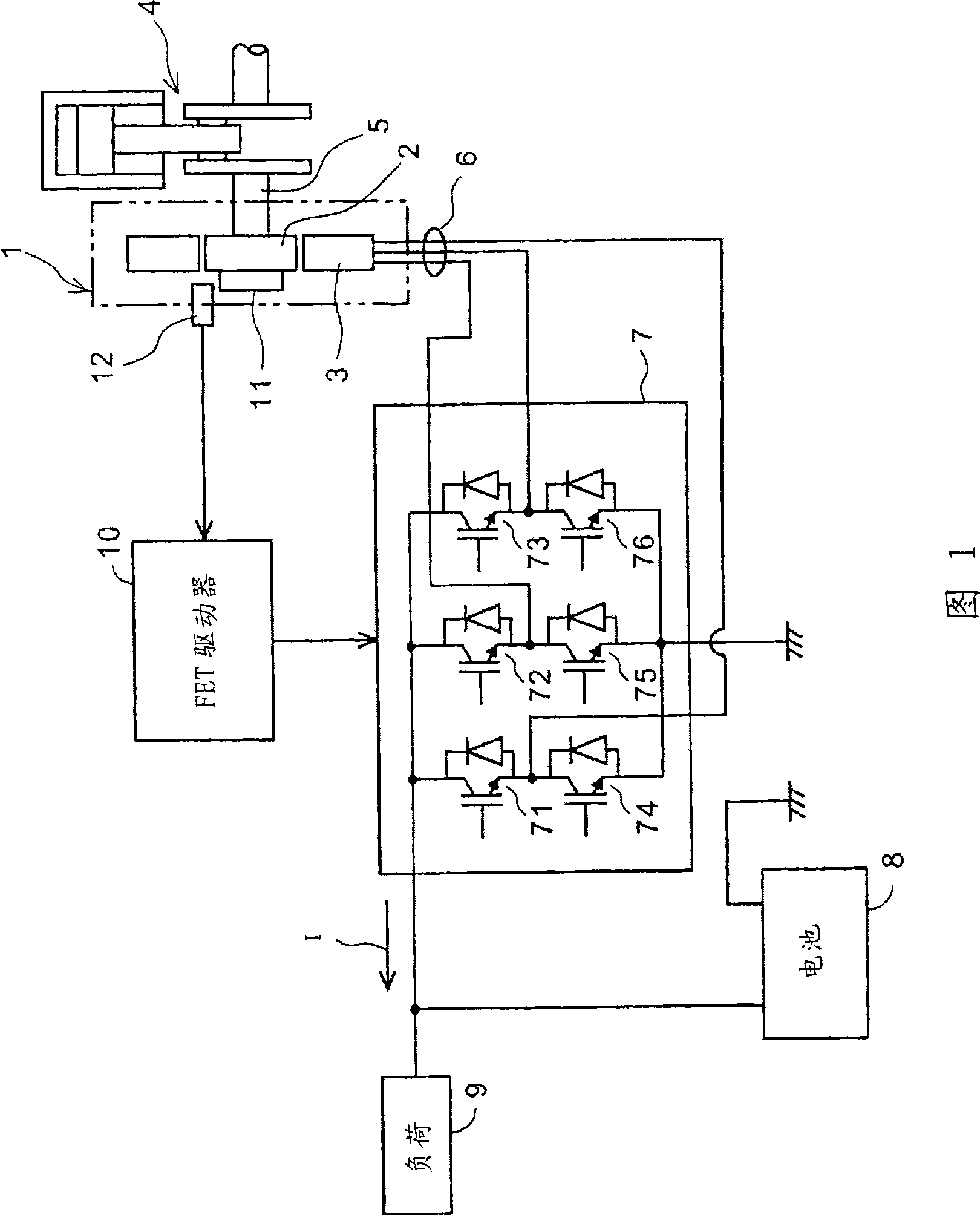

[0026] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. FIG. 1 is a diagram showing a system configuration of a charge control device according to an embodiment of the power generation control device of the present invention.

[0027] In FIG. 1 , a generator 1 is composed of an internal gear 2 and an external stator 3 , and the internal gear 2 is connected to one end of a crankshaft 5 of a four-cycle engine 4 . The outer stator 3 has a three-phase output coil 6 connected to an input side of a switching circuit 7 . The output side of the switch circuit 7 is connected to the battery 8 and the load 9 . The switch circuit 7 is a three-phase bridge circuit composed of six FETs 71 , 72 , 73 , 74 , 75 , and 76 . The FET driver 10 is provided as an output control device that changes the energization phases of the FETs 71 to 76 of the switch circuit 7 to perform duty control.

[0028] The internal gear 2 of the generator 1 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com