Lubricant additive with ultra-lubrication antifriction function

A lubricating oil additive and lubricating oil technology, applied in additives, lubricating compositions, petroleum industry, etc., can solve the problems affecting the self-healing ability of self-healing materials, the pass rate is less than 40%, and there is no self-healing effect, etc., and the coefficient of friction can be achieved Small, easy to operate, easy to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

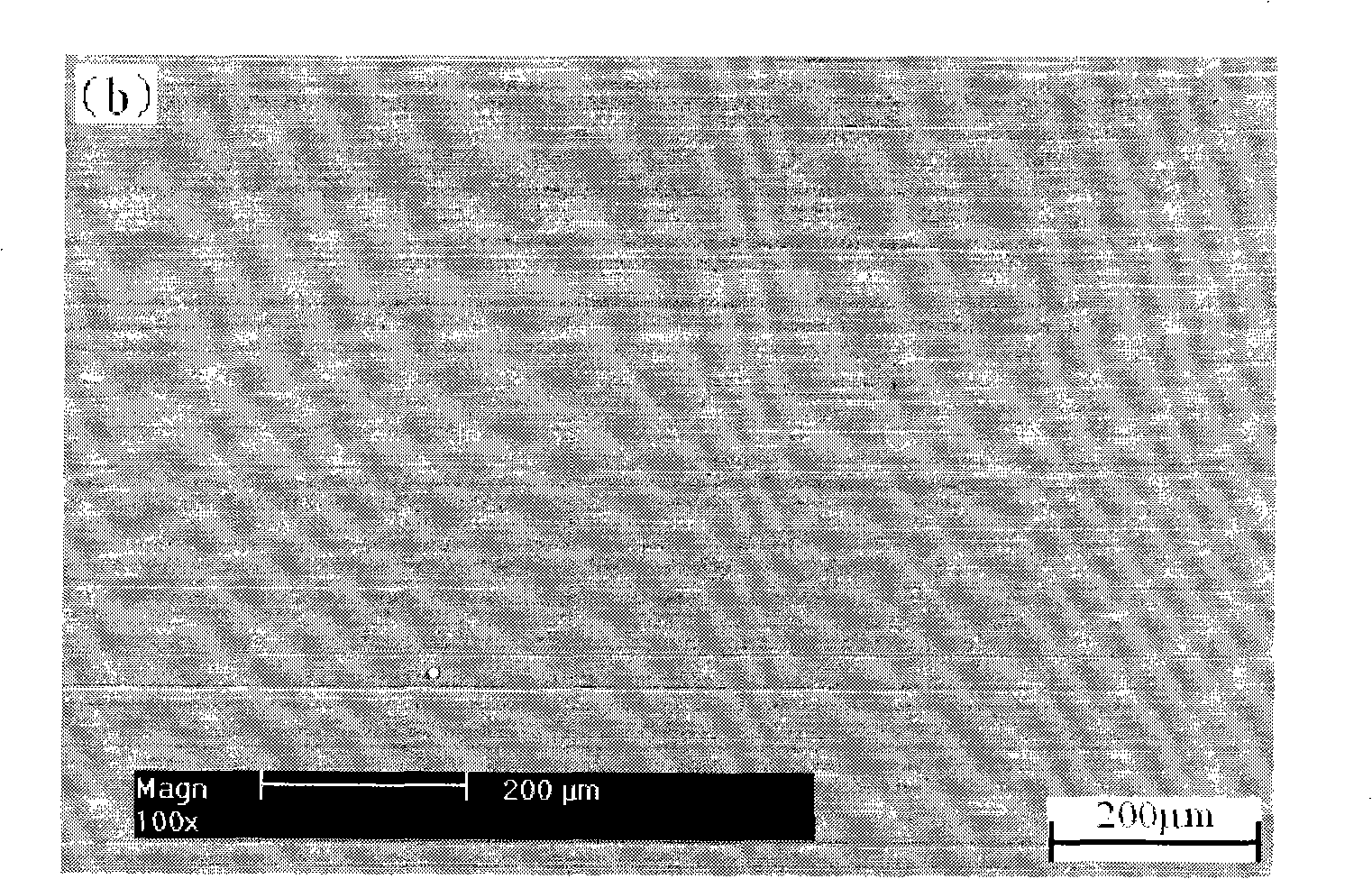

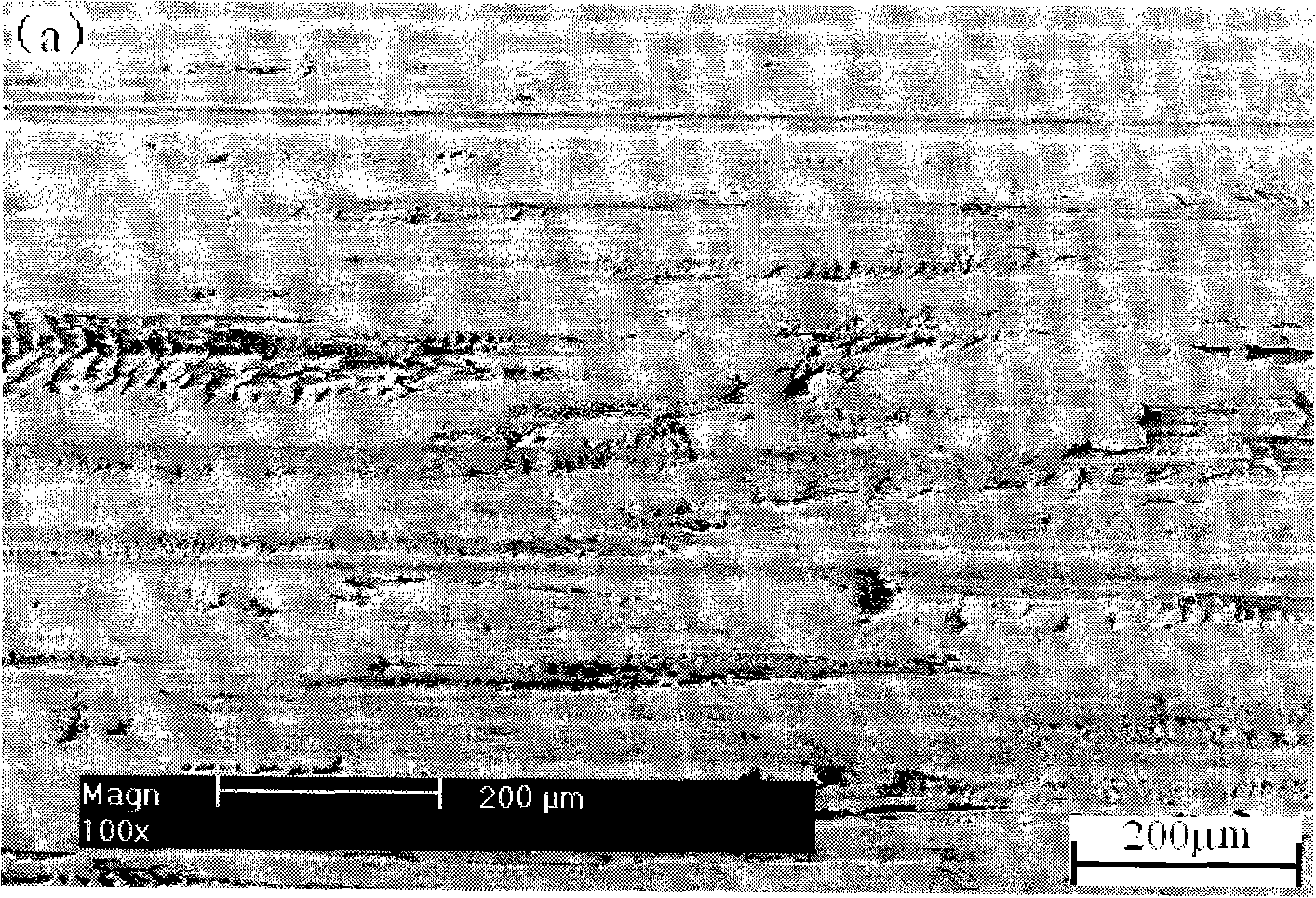

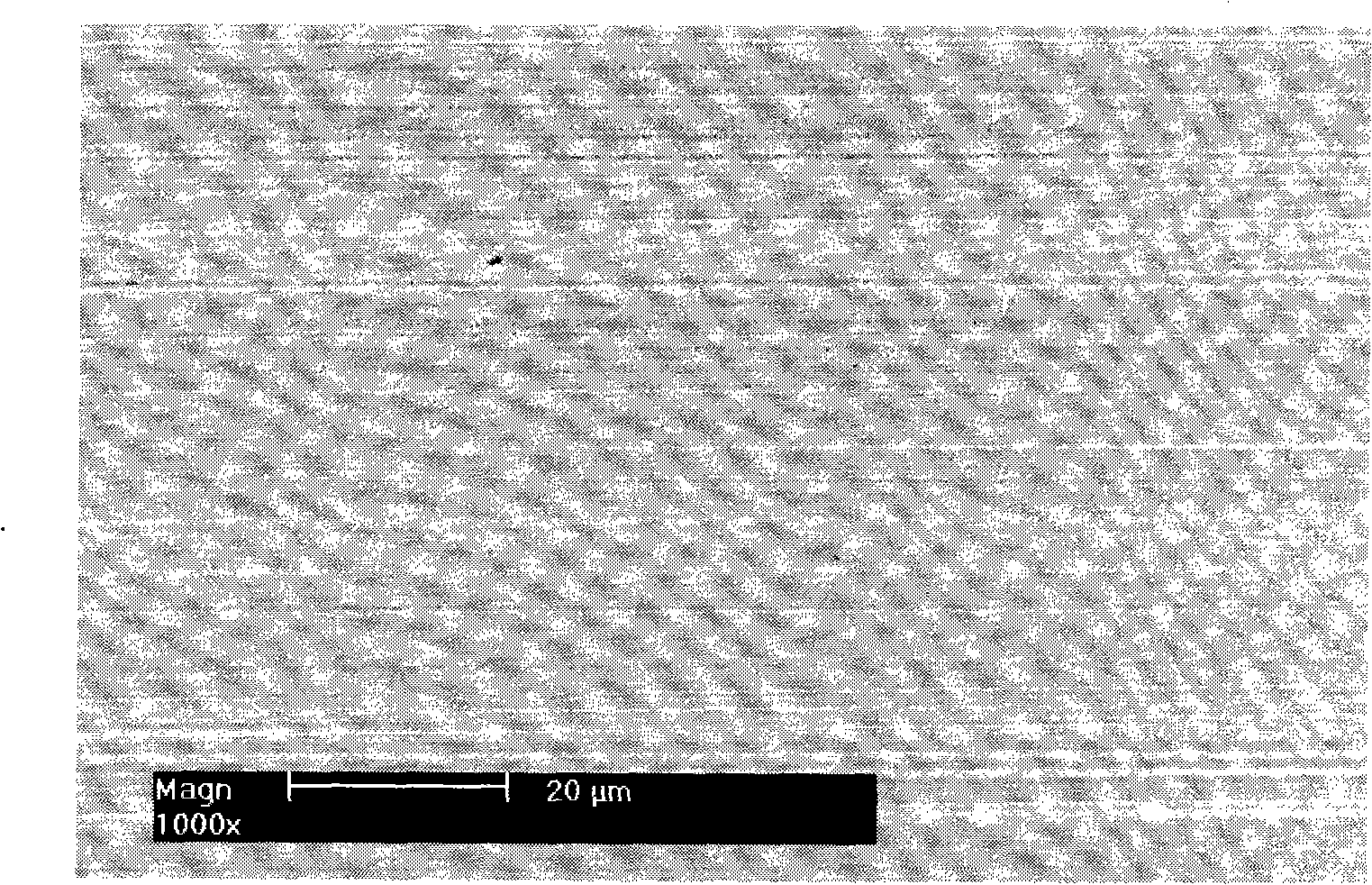

Image

Examples

Embodiment 1

[0023] Prepare a lubricating oil additive with super-lubricating and anti-friction effect with a ratio of 1:1 of serpentine and quartzite ultra-fine ore composite powder:

[0024] (1) Preparation of powder: Serpentine and quartzite ore are respectively ball milled to become powders with a particle size of less than 5 μm;

[0025] (2) Preparation of composite powder: mix serpentine and quartzite ultrafine ore composite powder in a ratio of 1:1, add 0.005% oleic acid in powder mass percentage, continue ball milling for 6 hours, and modify the surface of the composite powder and mixing to fully homogenize the mixed powder to obtain a composite powder. The modified ultrafine composite powder has good suspension and compatibility properties in lubricating oil;

[0026] (3) Dispersed in lubricating oil: the above-mentioned modified and mixed ultrafine composite powder is used as a lubricating oil additive, and is added to the lubricating oil at a ratio of 2% by mass, and is fully st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com