Novolac epoxy scraper and manufacturing method thereof

A phenolic epoxy resin and a manufacturing method of technology, applied in the direction of scraper, paper making, paper making machine, etc., can solve the problems of shutdown, poor temperature resistance, black marks, etc., and achieve a reasonable process route, firm installation, and strong straightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

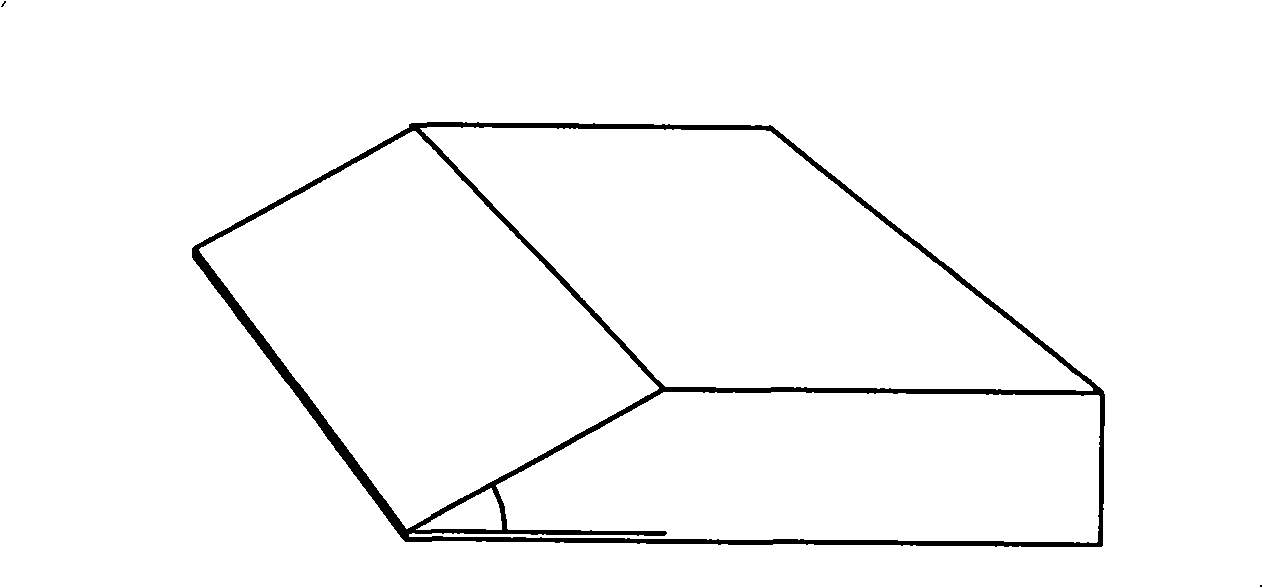

[0041] Example 1 see figure 1 , figure 2 , image 3 shown

[0042] One, a kind of manufacture method of phenolic epoxy resin scraper, its steps are as follows:

[0043] (1) Preparation of scraper base material: resin glue is selected as the base material, and the component weight ratio of the resin glue is as follows:

[0044] 38 parts of NPPN638S phenolic epoxy resin, 2 parts of epoxy resin toughening agent, 5 parts of dicyandiamide,

[0045] 0.005 parts of imidazole, 14 parts of dimethylformamide, 10 parts of acetone, 15 parts of silicon micropowder, 1.5 parts of molybdenum disulfide;

[0046] (2) The multi-layer carbon fiber cloth is glued at a high temperature of 160 degrees, and then pressed and cured at a temperature of 260 degrees and a pressure of 80 kilograms per square centimeter.

[0047] Two, the shape structure of a kind of phenolic epoxy resin scraper is as follows:

[0048] The novolac epoxy resin scraper made of the above-mentioned base material has the ...

Embodiment 2

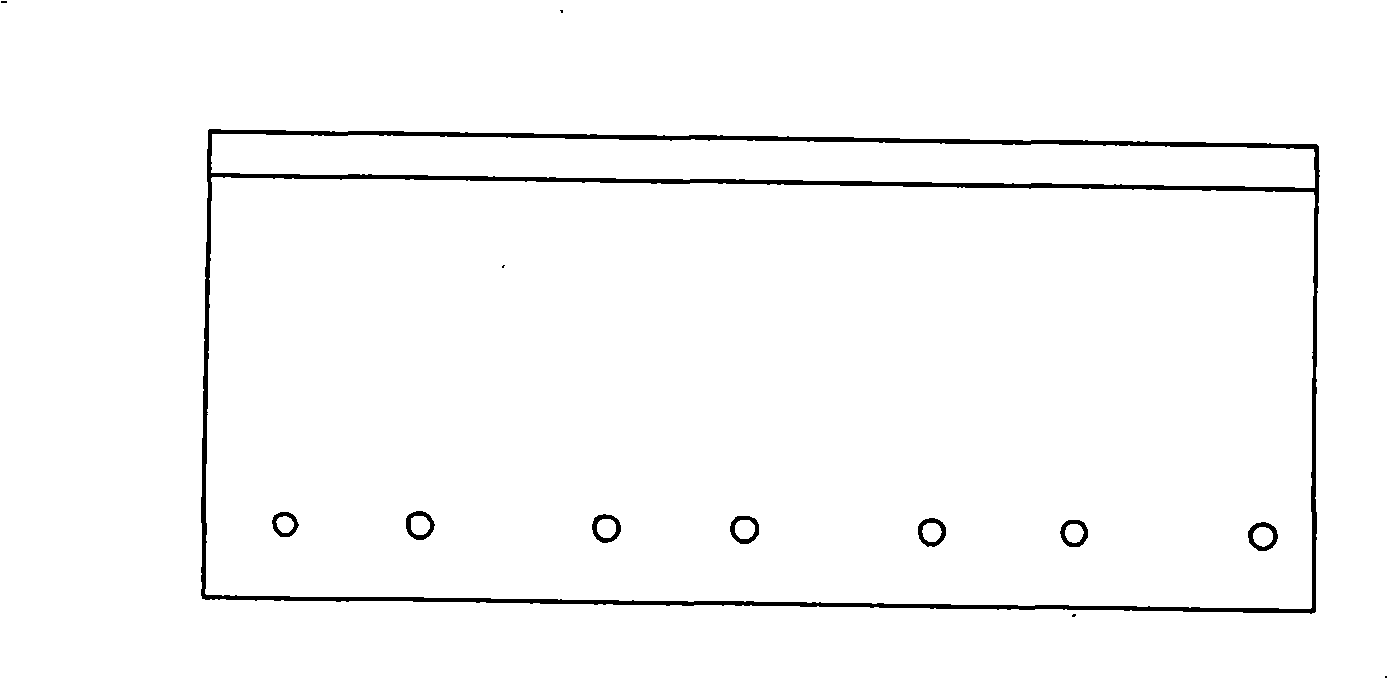

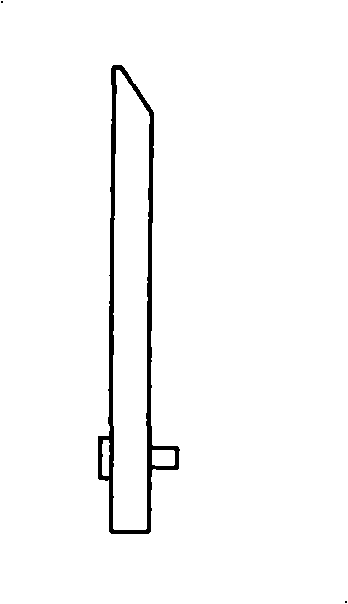

[0050] Example 2 see figure 1 , Figure 4 , Figure 5 shown

[0051] One, a kind of manufacture method of phenolic epoxy resin scraper, its steps are as follows:

[0052] (1) Preparation of scraper base material: resin glue is selected as the base material, and the component weight ratio of the resin glue is as follows:

[0053] 42 parts of KEP-1138 novolac epoxy resin, 2 parts of epoxy resin toughening agent, 5 parts of dicyandiamide, 0.006 parts of imidazole, 15 parts of dimethylformamide, 10 parts of acetone, 16 parts of silicon micropowder, 1.5 parts of molybdenum disulfide share;

[0054] (2) The multi-layer glass fiber cloth is glued at a high temperature of 160 degrees, and then pressed and cured at a temperature of 260 degrees and a pressure of 80 kilograms per square centimeter.

[0055] Two, the shape structure of a kind of phenolic epoxy resin scraper is as follows:

[0056] The novolac epoxy resin scraper made of the above-mentioned base material has the foll...

Embodiment 3

[0058] Example 3 see figure 1 , Figure 6 , Figure 7 shown

[0059] One, a kind of manufacture method of phenolic epoxy resin scraper, its steps are as follows:

[0060] (1) Preparation of scraper base material: resin glue is selected as the base material, and the component weight ratio of the resin glue is as follows:

[0061] 40 parts of F51 novolak epoxy resin, 2 parts of epoxy resin toughening agent, 5 parts of dicyandiamide, 0.007 part of imidazole, 14 parts of dimethylformamide, 10 parts of acetone, 15 parts of silicon micropowder, 1.5 parts of molybdenum disulfide;

[0062] (2) The multi-layer carbon fiber cloth is glued at a high temperature of 160 degrees, and then pressed and cured at a temperature of 260 degrees and a pressure of 80 kilograms per square centimeter.

[0063] Two, the shape structure of a kind of phenolic epoxy resin scraper is as follows:

[0064] The novolac epoxy resin scraper made of the above-mentioned base material has the following struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com