Novolac epoxy scraper and manufacturing method thereof

A novolac epoxy resin and manufacturing method technology, applied in the direction of scraper, paper making, paper machine, etc., can solve the problems of downtime, poor temperature resistance, stained with black marks, etc., and achieve reasonable process route, strong straightness, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

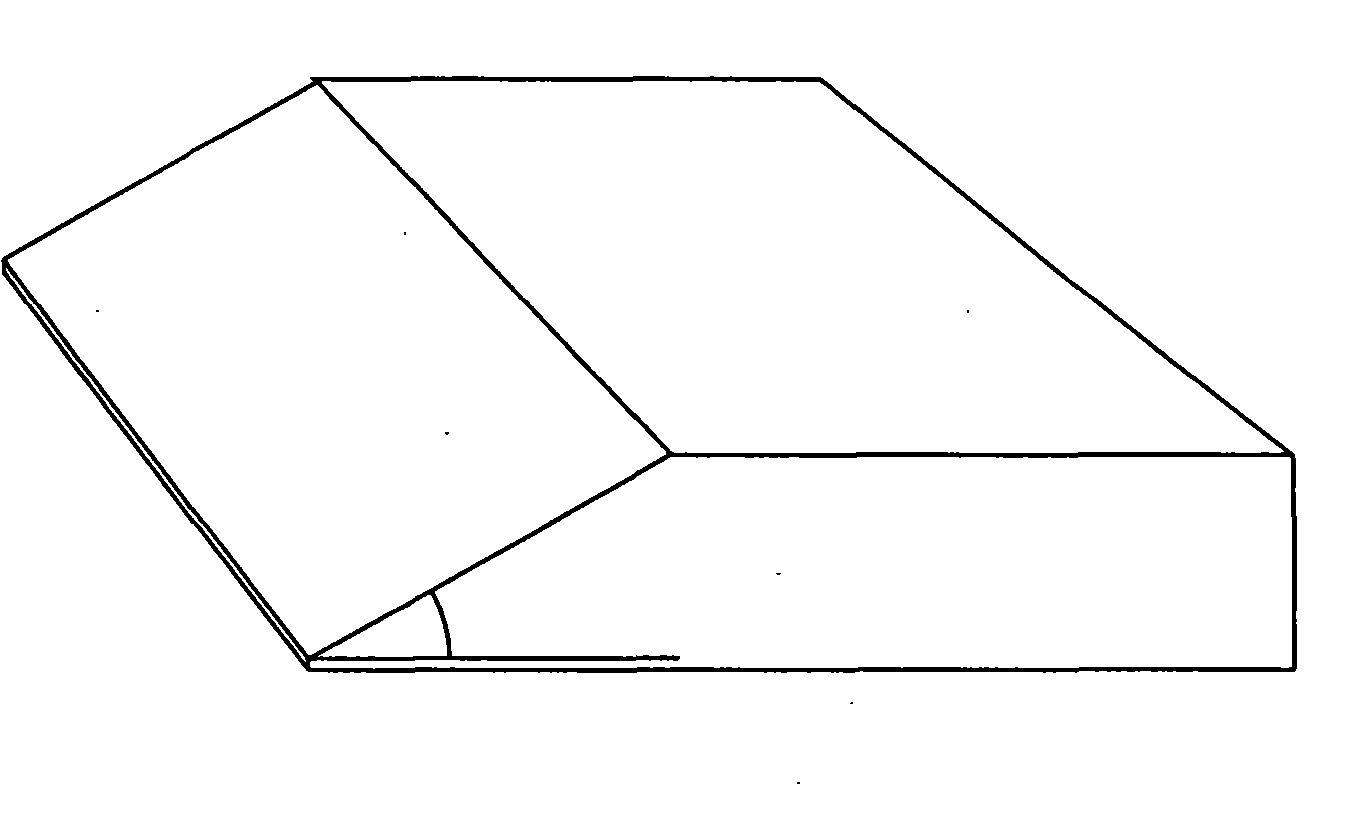

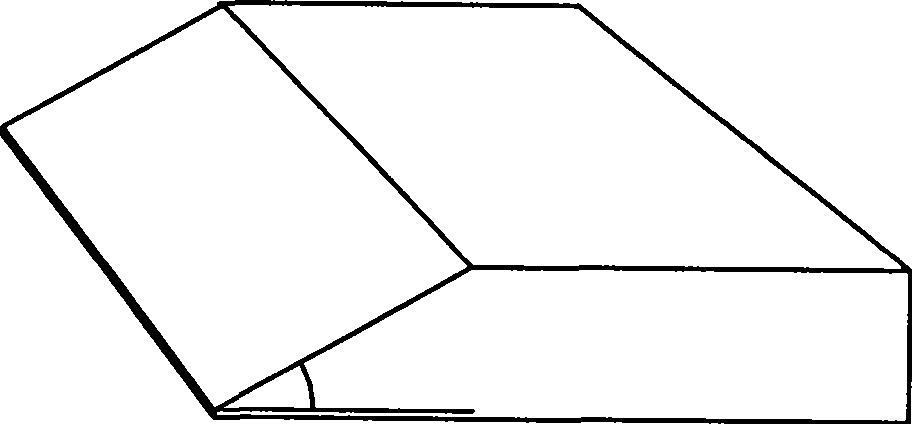

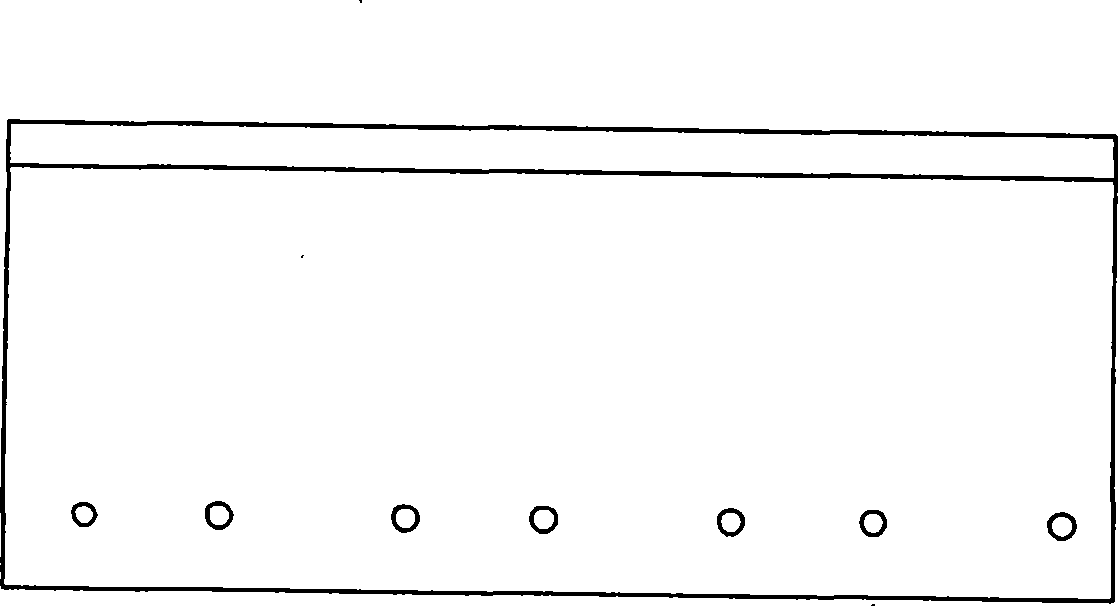

[0040] Embodiment 1 is shown in Fig. 1, Fig. 2, Fig. 3

[0041] One, a kind of manufacture method of phenolic epoxy resin scraper, its steps are as follows:

[0042] (1) Preparation of scraper base material: resin glue is used as the base material, and the components by weight of the resin glue are as follows: 38 parts of NPPN638S novolac epoxy resin, 2 parts of epoxy resin toughening agent, 5 parts of dicyandiamide, 0.005 parts of imidazole, 14 parts of dimethylformamide, 10 parts of acetone, 15 parts of silicon micropowder, 1.5 parts of molybdenum disulfide;

[0043] (2) The multi-layer carbon fiber cloth is glued at a high temperature of 160 degrees, and then pressed and cured at a temperature of 260 degrees and a pressure of 80 kilograms per square centimeter.

[0044] Two, the shape structure of a kind of phenolic epoxy resin scraper is as follows:

[0045] The novolak epoxy resin scraper manufactured by the above-mentioned base material has a structural form: the lengt...

Embodiment 2

[0046] Embodiment 2 is shown in Fig. 1, Fig. 4, Fig. 5

[0047] One, a kind of manufacture method of phenolic epoxy resin scraper, its steps are as follows:

[0048] (1) Preparation of scraper base material: resin glue is used as the base material, and the component weight ratio of the resin glue is as follows: 42 parts of KEP-1138 novolac epoxy resin, 2 parts of epoxy resin toughening agent, 5 parts of dicyandiamide 0.006 parts of imidazole, 15 parts of dimethylformamide, 10 parts of acetone, 16 parts of microsilica powder, and 1.5 parts of molybdenum disulfide;

[0049] (2) The multi-layer glass fiber cloth is glued at a high temperature of 160 degrees, and then pressed and cured at a temperature of 260 degrees and a pressure of 80 kilograms per square centimeter.

[0050] Two, the shape structure of a kind of phenolic epoxy resin scraper is as follows:

[0051] The novolac epoxy resin scraper manufactured by the above-mentioned base material has a structural form: the len...

Embodiment 3

[0052] Embodiment 3 is shown in Fig. 1, Fig. 6, Fig. 7

[0053] One, a kind of manufacture method of phenolic epoxy resin scraper, its steps are as follows:

[0054] (1) Preparation of scraper base material: resin glue is selected as the base material, and the component weight ratio of the resin glue is as follows: 40 parts of F51 novolac epoxy resin, 2 parts of epoxy resin toughening agent, 5 parts of dicyandiamide, 0.007 parts of imidazole, 14 parts of dimethylformamide, 10 parts of acetone, 15 parts of silicon micropowder, and 1.5 parts of molybdenum disulfide;

[0055] (2) The multi-layer carbon fiber cloth is glued at a high temperature of 160 degrees, and then pressed and cured at a temperature of 260 degrees and a pressure of 80 kilograms per square centimeter.

[0056] Two, the shape structure of a kind of phenolic epoxy resin scraper is as follows:

[0057] The novolac epoxy resin scraper manufactured by the above-mentioned base material has a structural form: the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com