Liquid gas gasification method and its circulation type gasification apparatus

A gasification device, liquefied gas technology, applied in the method of container discharge, fixed-capacity gas storage tank, gas/liquid distribution and storage, etc., can solve the problems of insufficient heat absorption area, loss of gasification capacity, condensation, etc., Achieve the effect of high heat exchange efficiency, low manufacturing cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

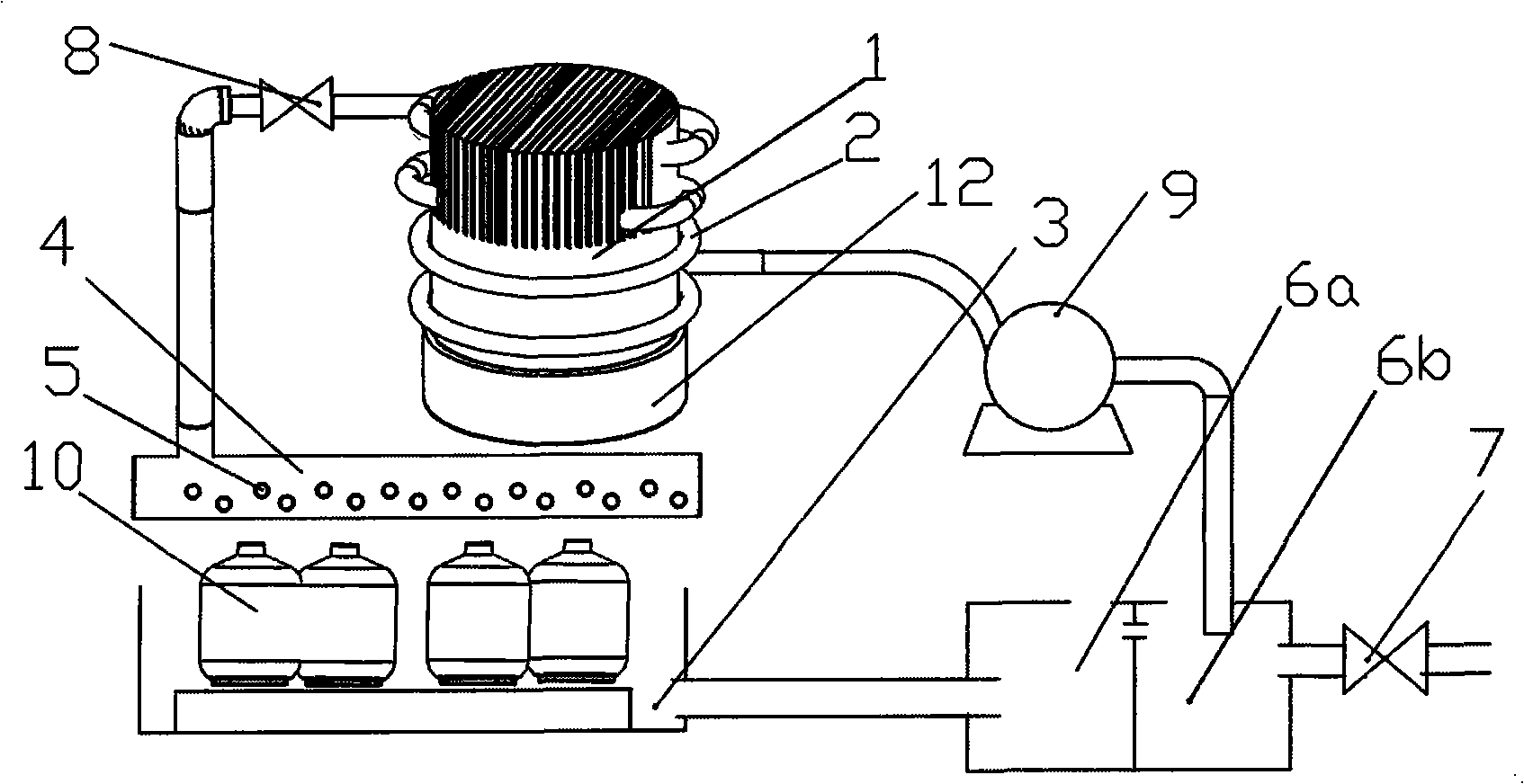

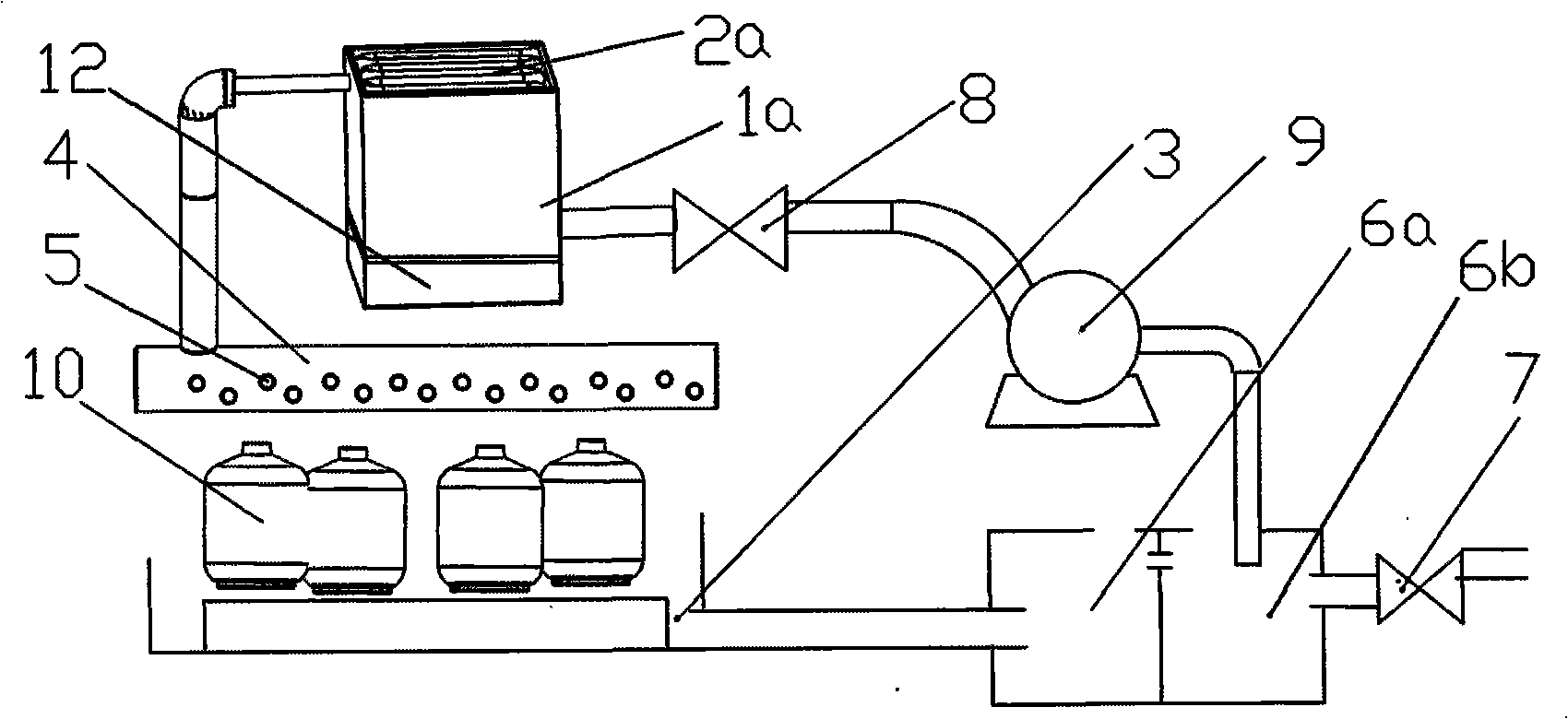

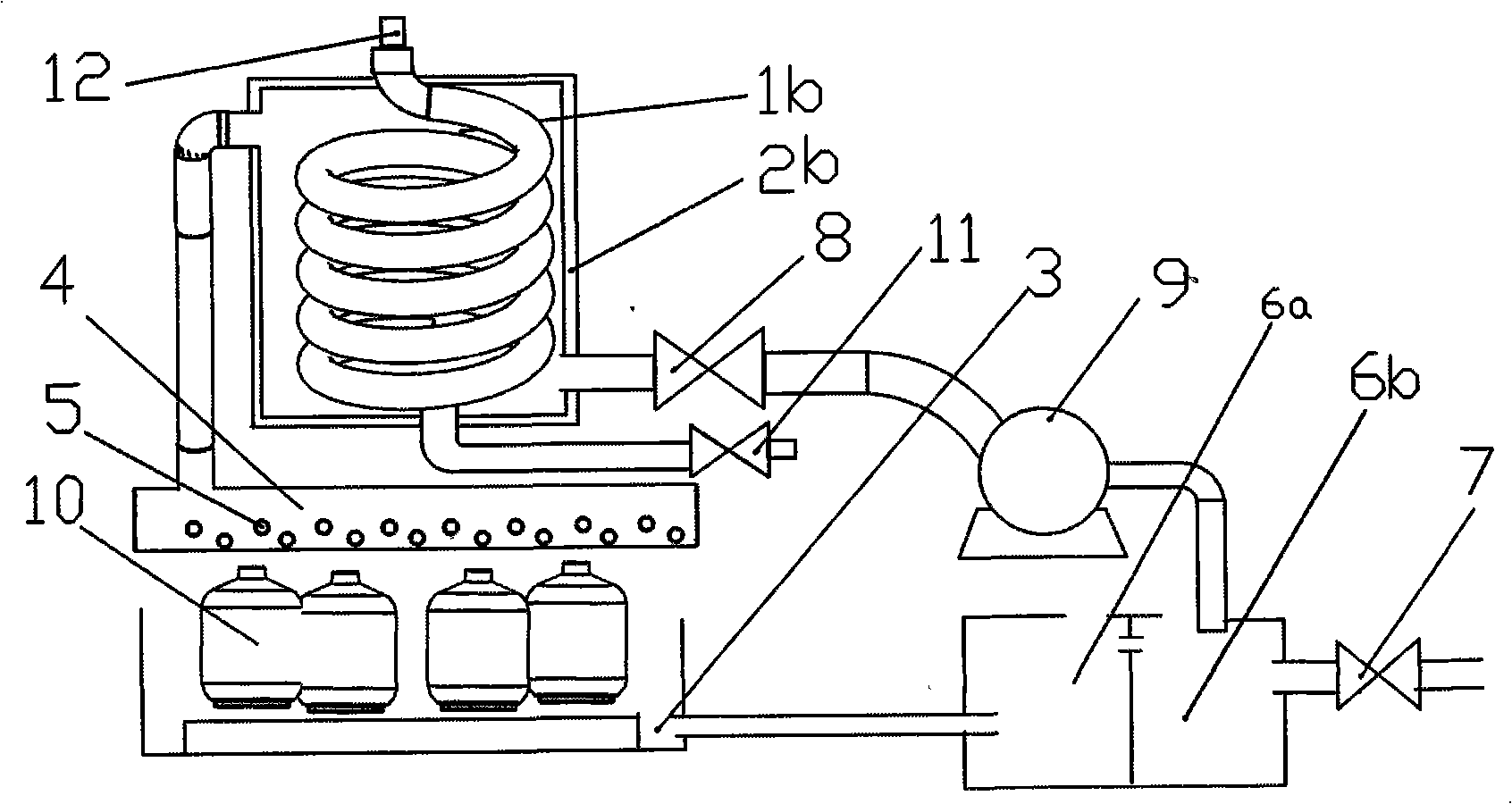

[0016] The present invention will be described in detail in conjunction with the accompanying drawings and embodiments. Such as figure 1 As shown, the lower end of the tube radiator and the fin radiator is connected as one, and the boiler exhaust port 12 is connected with the tube radiator. The part of the heat absorbing coil 2 corresponding to the fin radiator is wound on the fin radiator, and the part corresponding to the tube radiator is wound on the tube radiator. The upper outlet of the heat-absorbing coil 2 is connected to the laterally arranged spray pipe 4 through a valve 8 . A water collection tank 3 is correspondingly provided below the spray pipe 4 , and the air storage tank 10 is placed on the water collection tank 3 corresponding to the water spray hole 5 of the spray pipe 4 . The purification tank is composed of a recovery tank 6a and a water storage tank 6b connected to each other. The water collection tank 3 is connected to the recovery tank 6a. 6b. The rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com