Multifunctional composite core aluminum stranded wire and cable

An aluminum stranded wire and composite core technology, applied in the direction of insulated cables, communication cables, cables, etc., can solve the problems of strength loss, reduction of composite core tensile strength, difficult to find and detect, to prevent overload and reduce galloping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

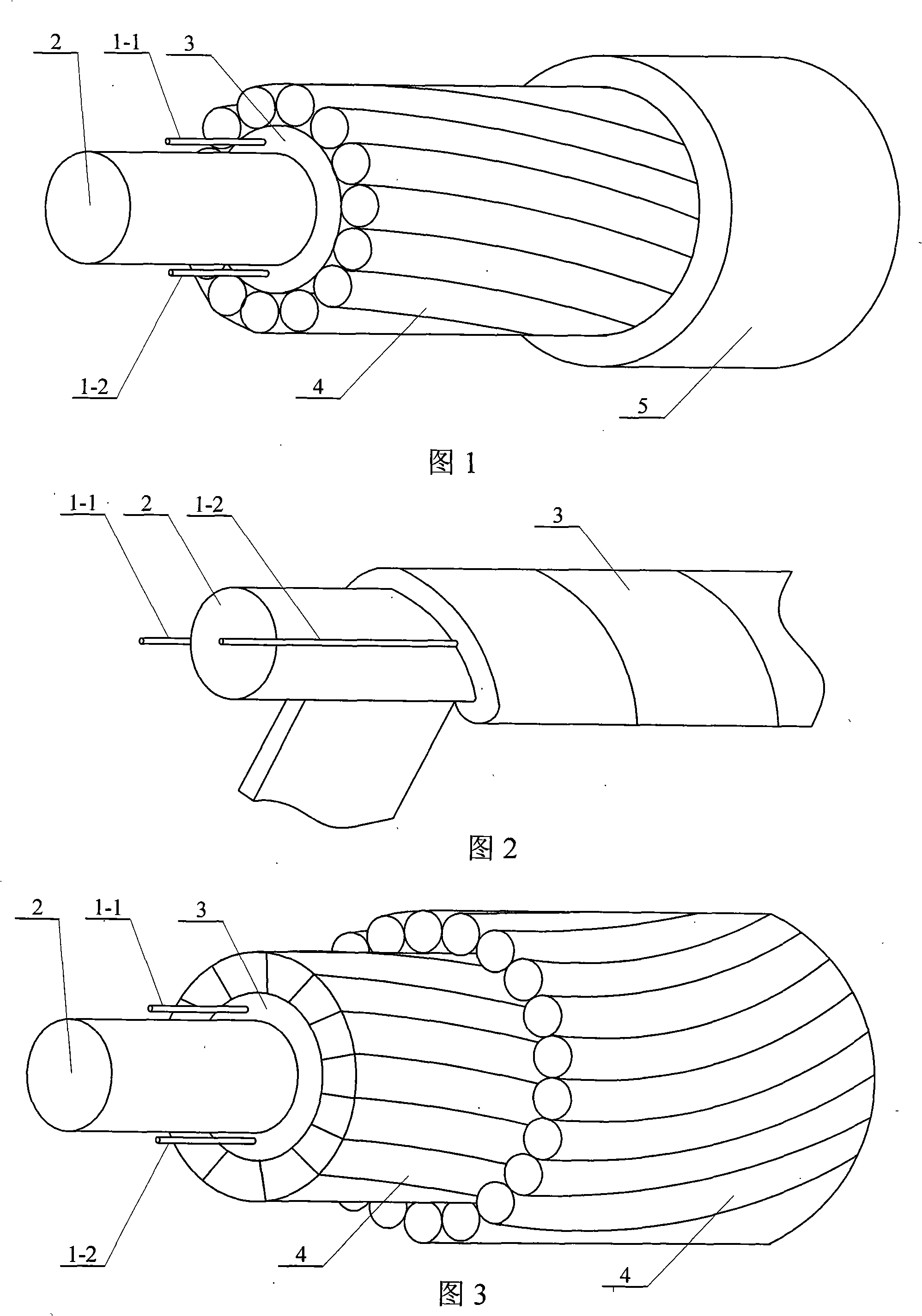

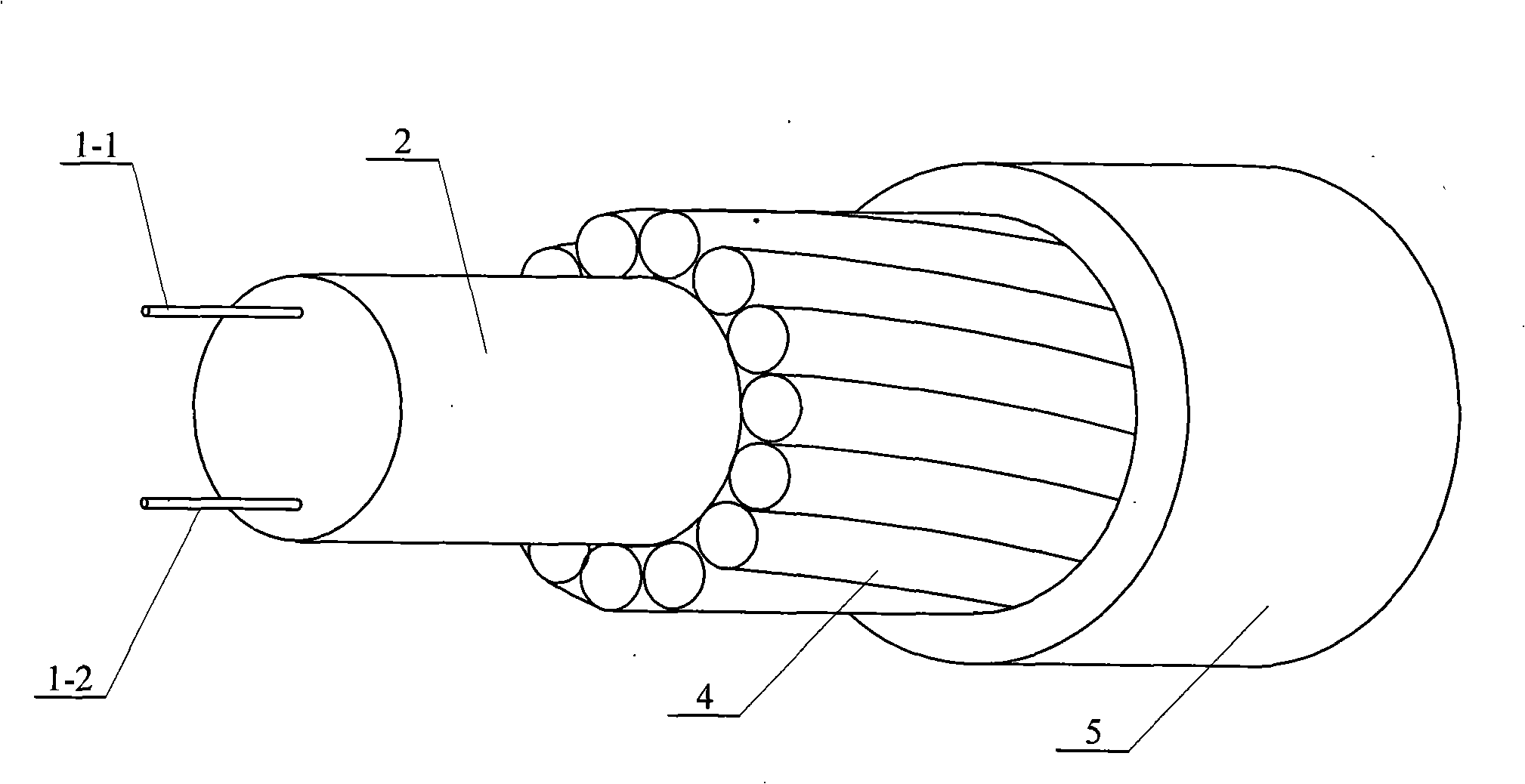

[0007] Specific implementation mode one: (see Figure 4 ) The multifunctional composite core aluminum stranded wire of this embodiment includes a composite material inner core 2 and an aluminum stranded wire 4, the exterior of the composite material inner core 2 is provided with an aluminum stranded wire 4, and the multifunctional composite core aluminum stranded wire also includes temperature and stress Sensing optical fiber 1-1, the temperature and stress sensing optical fiber 1-1 is arranged in the inner core 2 of composite material.

specific Embodiment approach 2

[0008] Specific embodiment two: (see Fig. 2) the multifunctional composite core aluminum stranded wire of the present embodiment comprises composite material inner core 2, outer core 3 and aluminum stranded wire 4, and the exterior of composite material inner core 2 is provided with outer core 3, The outer core 3 is provided with an aluminum stranded wire 4, and the multifunctional composite core aluminum stranded wire also includes a temperature and stress sensing optical fiber 1-1, and the temperature and stress sensing optical fiber 1-1 is arranged on the inner core 2 and Between the outer core 3.

specific Embodiment approach 3

[0009] Specific embodiment three: (see Fig. 3) the multifunctional composite core aluminum stranded wire of the present embodiment comprises composite material inner core 2, outer core 3 and aluminum stranded wire 4, and the exterior of composite material inner core 2 is provided with outer core 3, The outer core 3 is provided with an aluminum stranded wire 4 , the multifunctional composite core aluminum stranded wire also includes a temperature and stress sensing optical fiber 1 - 1 , and the temperature and stress sensing optical fiber 1 - 1 is arranged inside the outer core 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com