Technology for improving polyester esterification reaction speed

A technology of esterification reaction and technology, which is applied in chemical fiber and chemical industry, can solve the problems of large energy consumption and achieve the effects of less equipment investment, lower energy consumption and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

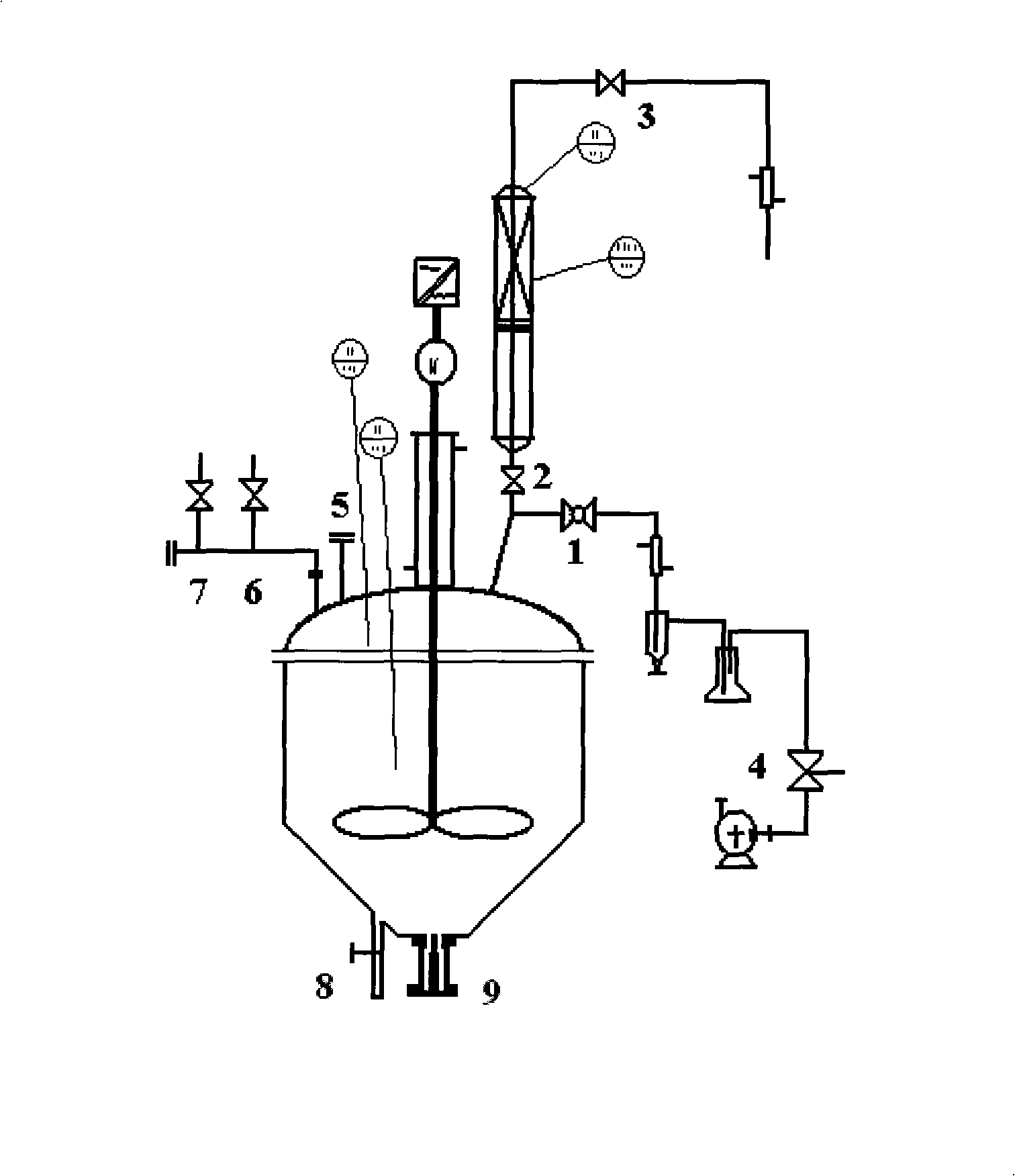

[0073] The reactor structure is as figure 1 As shown, among them: 1 is the vacuum valve, 2 is the inlet valve of the separation tower, 3 is the outlet valve of the separation tower, 4 is the three-way valve, 5 is the feeding port, 6 and 7 are the nitrogen interface and valve, 8 is the sampling valve , 9 is the discharge port.

[0074] According to the raw material ratio of PTA 5.0kg, EG 3.2kg, and antimony triacetate 2.5g, the materials are prepared and put into the reactor, the reactor is sealed, the gas phase air is replaced with nitrogen, and the temperature is raised. At the same time, feed nitrogen to maintain the internal pressure of the reactor at about 2.5kg / cm2 (gauge pressure). When the temperature of the reactor material reaches 230°C, the system pressure is about 2.5kg / cm2 (gauge pressure). Reaction conditions. Start to slowly open the water outlet valve of the separation tower (process tower), measure the water output, calculate the degree of completion of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com