Electronic component and method for manufacturing the same

A technology of electronic components and manufacturing methods, which is applied in the direction of electrical components, electrical solid devices, semiconductor/solid device components, etc., can solve problems such as weak bonding force, bending and damage of bonding substrates, and achieve good productivity and realize productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

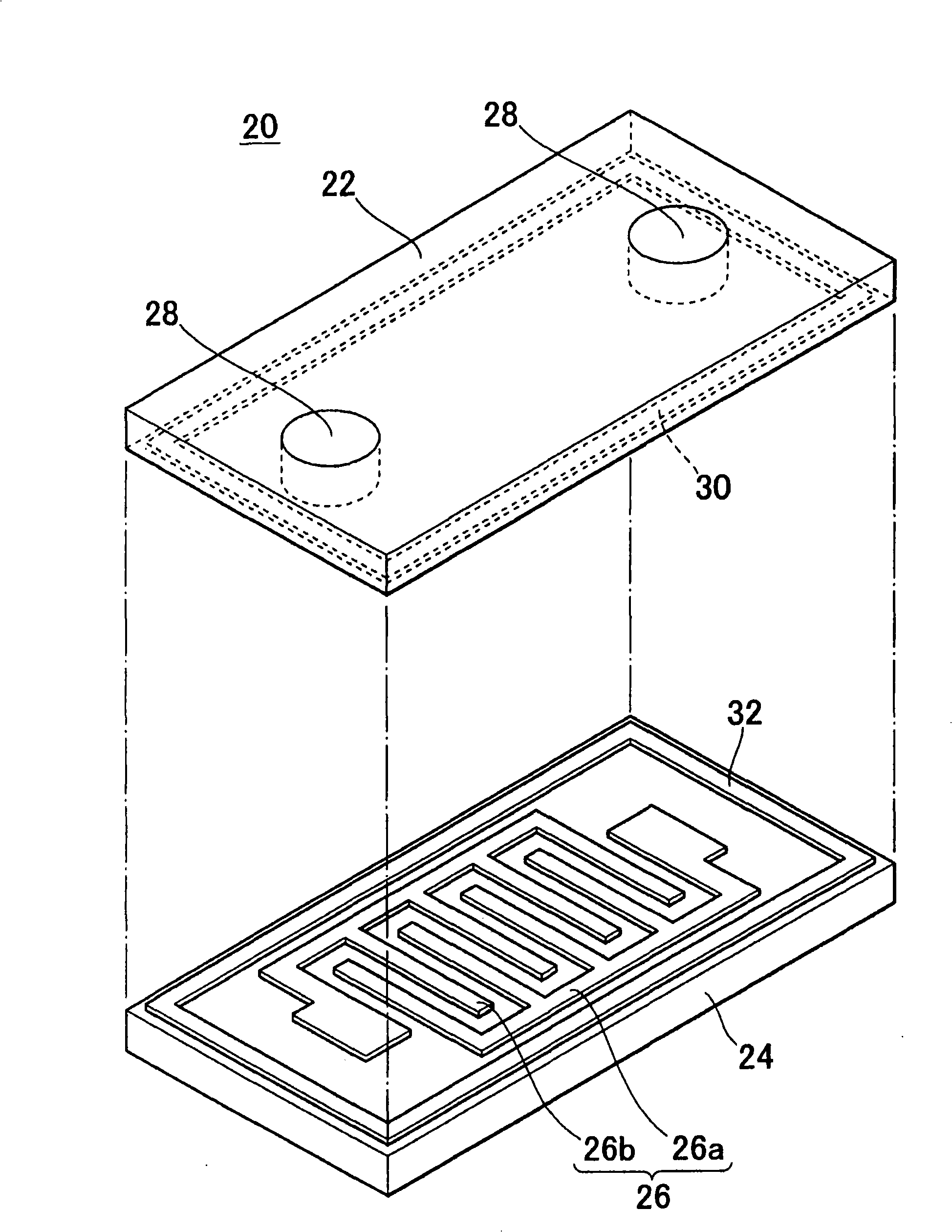

[0058] figure 1 It is an exploded perspective view showing an example of the electronic component of the present invention. Here, as the electronic component 20 , an electronic component formed with a surface acoustic wave element will be described, but an electronic component formed with another element may also be used. The electronic component 20 includes a first substrate 22 and a second substrate 24 . As the first substrate 22 used as the cover member, for example, silicon (Si) or the like is used, and as the second substrate 24 used as the substrate of the surface acoustic wave element, for example, LiTaO is used. 3 and other piezoelectric substrates. Among them, as the material of the first substrate 22 and the second substrate 24, in addition to the above-mentioned materials, LiNbO 3 , alumina, SiC, sapphire, crystal, Pb(Zr, Ti)O 3 , PbTiO 3 , BaTiO 3 , SrTiO 3 Wait.

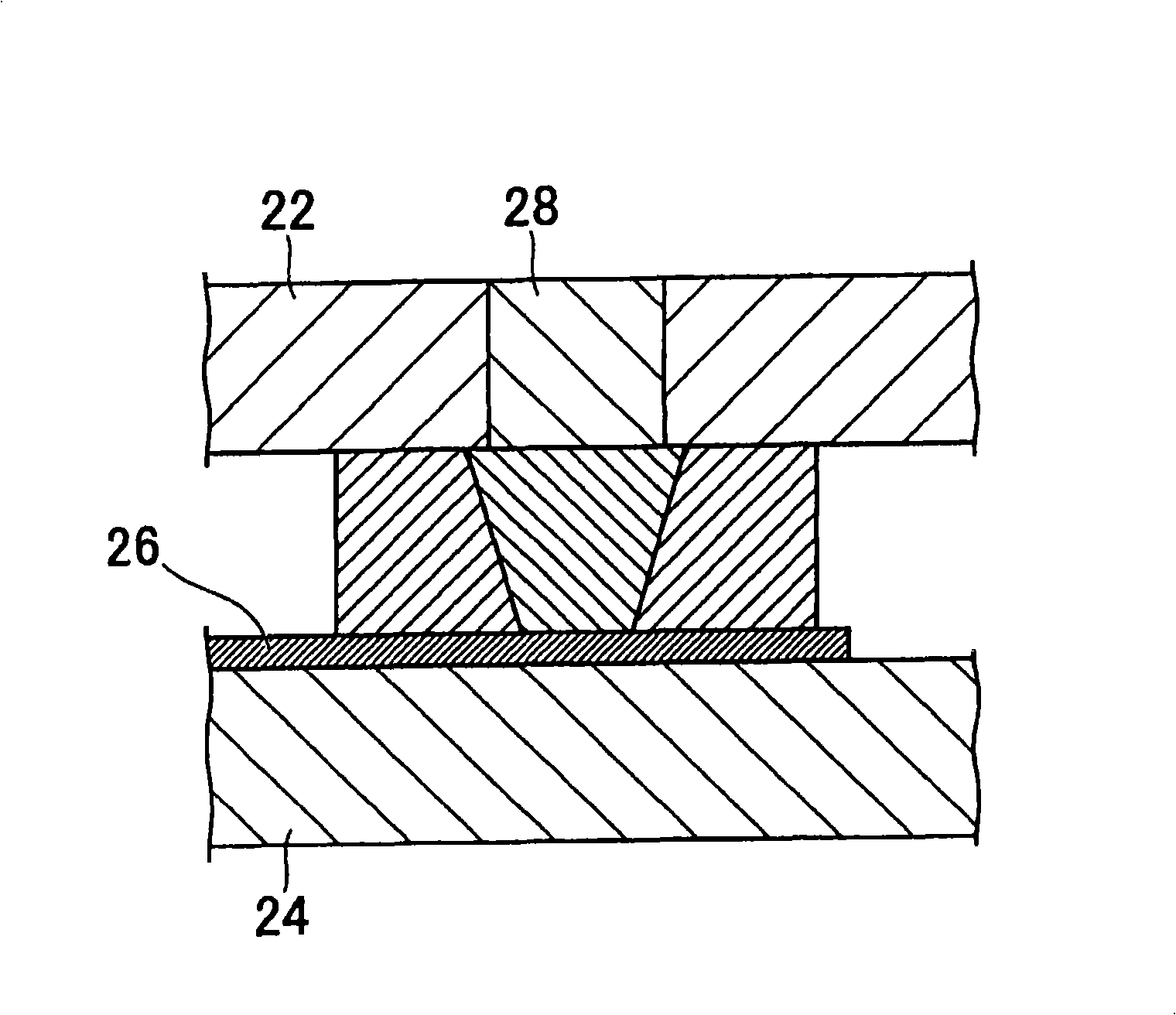

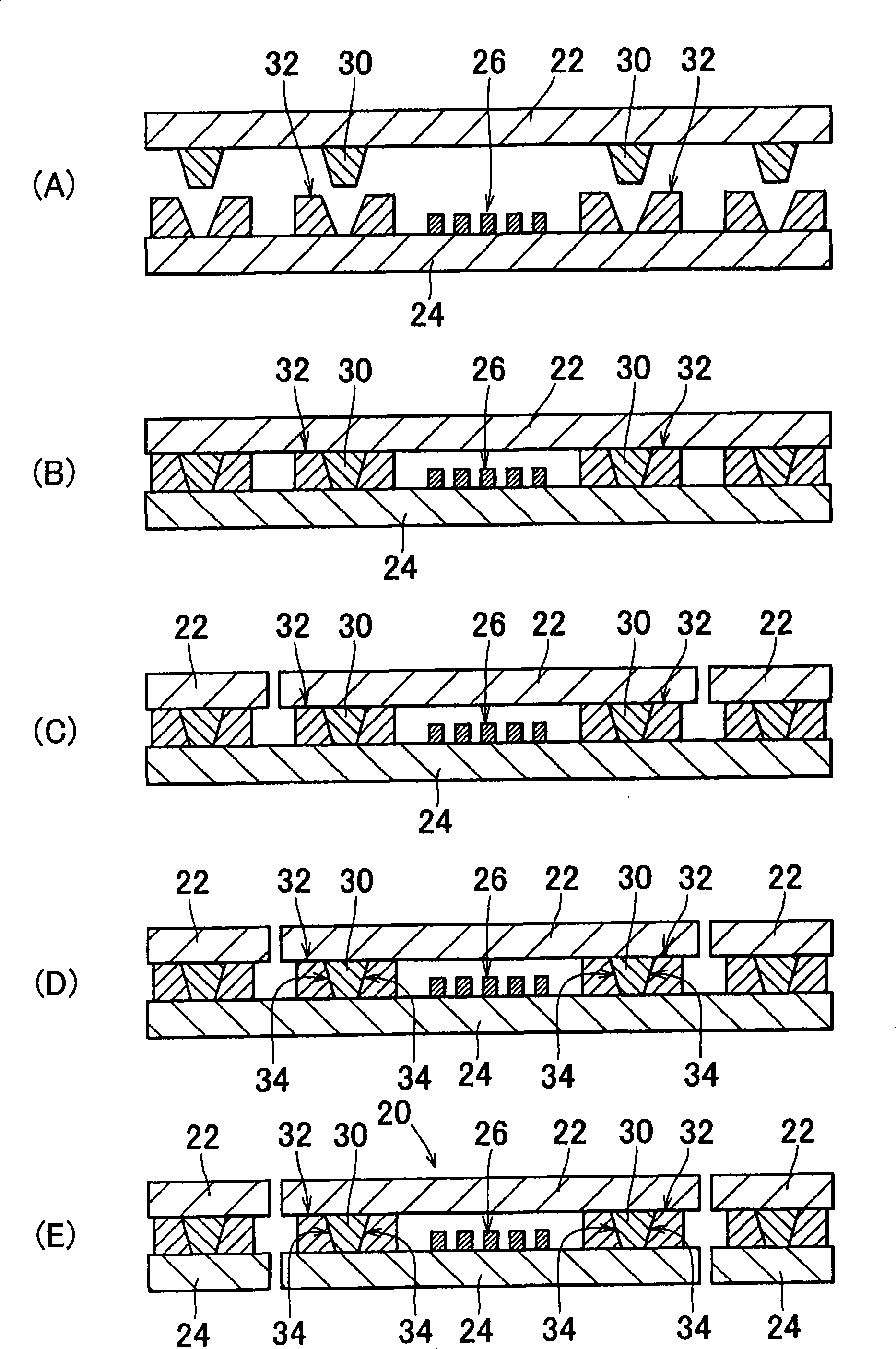

[0059] The first substrate 22 and the second substrate 24 are overlapped and bonded to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com